Ion Cleanse

Created by

[Khamees Mohamed Shaker Ibrahim]

• Started on June 12, 2025

A project focused on designing a 3D-modeled air filtration tower, supported by research, simulation, and technical documentation.

Project Journal: Ion Cleanse

Objective

To develop a 3D-modeled smart air filtration tower through a combination of computer-aided design, material analysis, airflow simulation, and thorough documentation. The project emphasizes technical depth and sustainability.

info about my Journey

Total Duration: 96 hours

Duration: 21 days

Start Date: 12 June 2025

End Date: 2 July 2025

Daily Log

Day 1 (12/6/2025) – 4 hours

- Ideated around core functionality of an outdoor smart filtration tower

- Sketched conceptual models

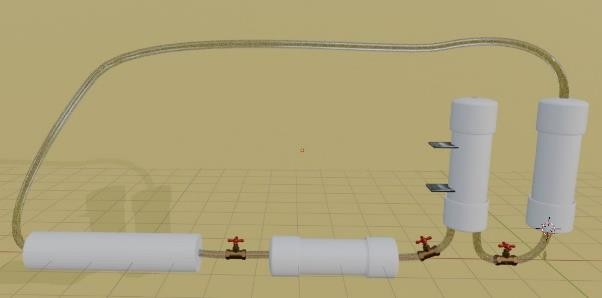

- Started basic 3D modeling of tower body

Day 2 (13/6/2025) – 4 hours

- Improved cylindrical geometry in CAD software

- Researched urban air filtration methods (HEPA vs. activated carbon)

- Documented CAD dimensions

Day 3 (14/6/2025) – 5 hours

- Integrated vent slats and hollow chambers into 3D design

- Compared pressure drop rates in vertical vs. horizontal filtering

- Created BOM draft for early-stage materials

Day 4 (15/6/2025) – 4 hours

- Ran preliminary airflow simulations (passive draw)

- Evaluated results vs. desired flow rate

- Adjusted vent geometry

Day 5 (16/6/2025) – 5 hours

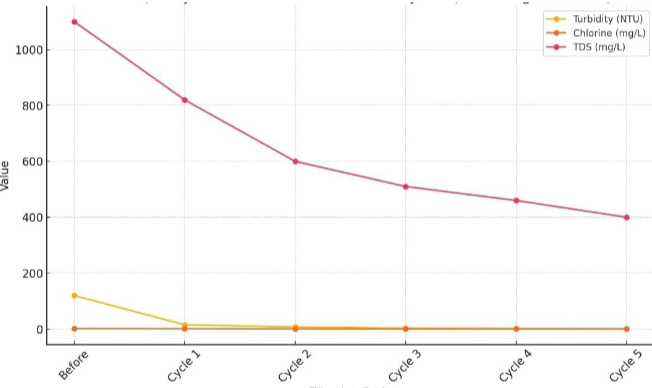

- Simulated particle behavior across filters

- Researched sustainable materials like coconut-shell carbon and aluminum mesh

- Logged simulation values into documentation

Day 6 (17/6/2025) – 4 hours

- Began cost and supplier comparison of key materials

- Integrated inlet sensors into design

- Wrote analysis of suitable filters for Egypt’s urban air quality

Day 7 (18/6/2025) – 4 hours

- Researched sensor placement strategies

- Modeled airflow-guiding vanes to increase efficiency

- Refined front-end mesh design

Day 8 (19/6/2025) – 5 hours

- Calculated airflow in m³/min across chambers

- Documented methodology for CFD simulation

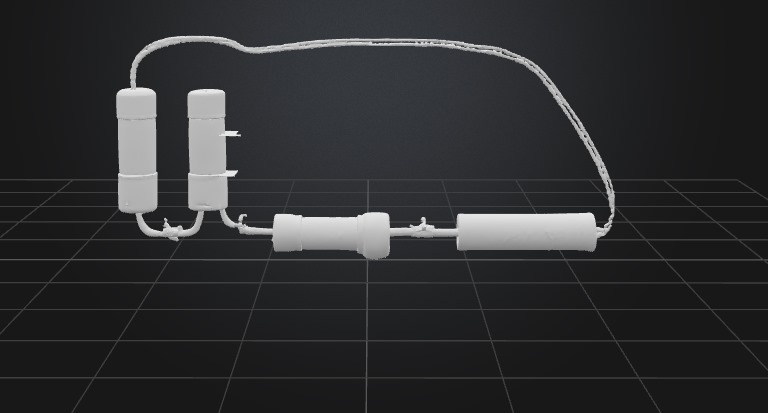

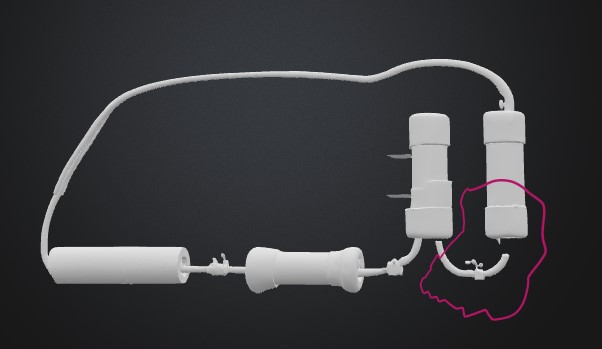

- Rendered early design prototype

Day 9 (20/6/2025) – 4 hours

- Re-evaluated simulation results with adjusted temperature and pressure

- Wrote progress documentation section

- Consulted academic paper on filtration efficiency

Day 10 (21/6/2025) – 4 hours

- Optimized air outlet shape

- Cross-compared three materials for outer casing (PVC vs. Aluminum vs. Recycled Plastic)

- Calculated expected operating temperature range

Day 11 (22/6/2025) – 5 hours

- Modeled base platform with cable routing

- Finalized 3D chamber segmentation

- Prepared simulation video exports

Day 12 (23/6/2025) – 4 hours

- Integrated digital display box into model

- Documented temperature sensor placement

- Exported technical drawings

Day 13 (24/6/2025) – 4 hours

- Simulated variable-speed fan integration

- Researched noise reduction techniques

- Wrote BOM with updated unit costs

Day 14 (25/6/2025) – 5 hours

- Conducted cost-to-efficiency analysis of final filter configuration

- Improved airflow simulation mesh resolution

- Designed branding plate

Day 15 (26/6/2025) – 4 hours

- Finalized 3D rendering with textures

- Compiled simulation results

- Created logo and interface icons

Day 16 (27/6/2025) – 4 hours

- Documented use-case scenarios (urban, factory perimeter, schools)

- Wrote methodology chapter for final report

- Searched environmental data from Cairo for validation

Day 17 (28/6/2025) – 5 hours

- Modeled transportable modular variant

- Designed solar-powered fan extension

- Calculated battery storage requirements

Day 18 (29/6/2025) – 4 hours

- Refined edge fillets for manufacture-readiness

- Finalized CAD file

- Prepared code blocks for sensor control (pseudo-code)

Day 19 (30/6/2025) – 4 hours

- Conducted peer review with teammates

- Integrated their feedback into final report

- Exported manufacturing-ready files

Day 20 (1/7/2025) – 4 hours

- Reviewed documentation and corrected structure

- Ensured citation of technical sources

- Proofread entire journal

Day 21 (2/7/2025) – 4 hours

- Submitted final files

- Compiled and packaged project repository

- Archived simulation runs and 3D exports