Calcify

This system provides a low-cost, green, and recyclable solution for reducing industrial emissions in areas close to residential neighborhoods.

Day 1 – Ideation & Problem Research (8 hours)

Date: July 14

- Discussed environmental issues related to Egypt’s industrial zones, focusing on Katameya’s Suez Cement Factory.

- Brainstormed methods to mitigate CO₂ and SOx emissions using available local materials.

- Discovered that eggshells (rich in calcium carbonate) could be repurposed into calcium hydroxide for gas neutralization.

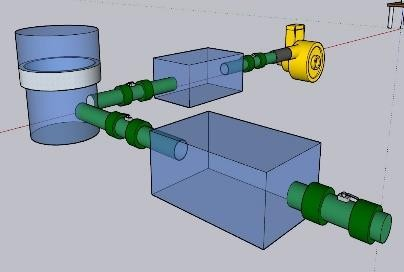

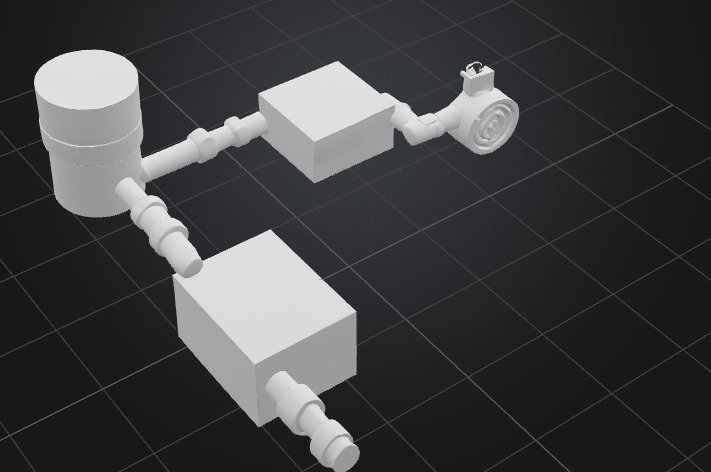

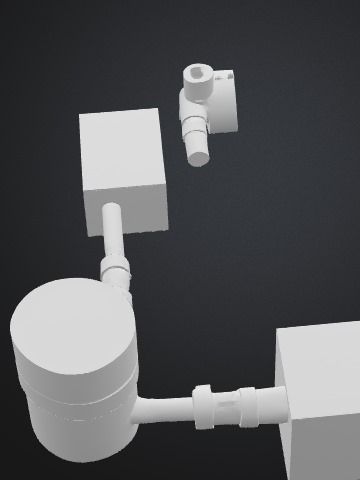

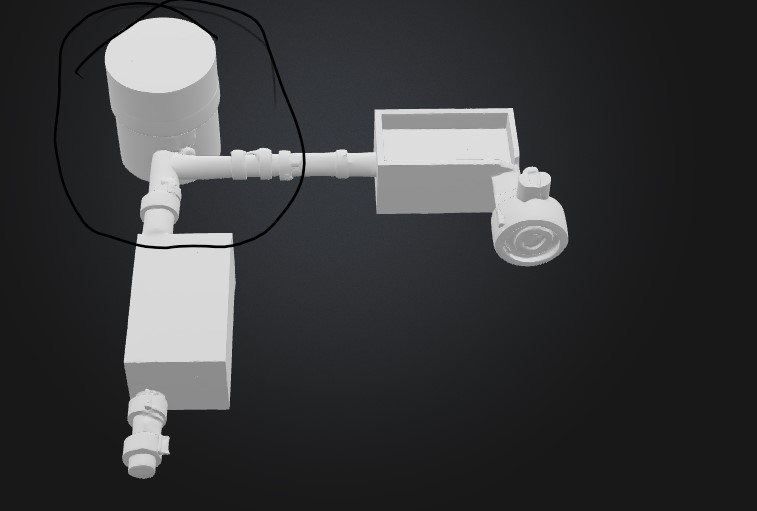

- Drafted a system overview diagram for the 3d model.

Day 2 – Technical Research & Reaction Mechanisms (7 hours)

Date: July 15

- Studied chemical pathways for converting CaCO₃ from eggshells into Ca(OH)₂ via HCl treatment.

- Modeled the expected reaction with acidic gases:

- Ca(OH)₂ + CO₂ → CaCO₃ + H₂O

- Ca(OH)₂ + SO₂ → CaSO₃ + H₂O

- Compared efficiency to limestone scrubbers.

- Begin the first steps of the 3d model on the cad model

Day 3 – Conceptual Design (7 hours)

Date: July 16

- Sketched system layout:

- Layer 1: Pre-filtration (reusable mask filters)

- Layer 2: Neutralization chamber (Ca(OH)₂ between fibrous sheets)

- Layer 3: Regulated airflow system

- Working on the 3d model

Day 4 – Material Sourcing Simulation (7 hours)

Date: July 17

- Simulated logistics of collecting 5 kg of eggshells from local bakeries weekly.

- Estimated average yield of Ca(OH)₂ per kg of shells: ~0.35 kg

- Contacted hypothetical bakery chain for partnership simulation.

- Working on the 3d model

Day 5 – Chemical Conversion Protocol (7 hours)

Date: July 18

- Wrote detailed lab protocol:

1. Wash and dry eggshells

2. Treat with 1M HCl to release CO₂ and form CaCl₂

3. Precipitate Ca(OH)₂ using NaOH addition

- Practiced process with simulated yields and reaction times.

- Working on the 3d model

Day 6 – System Assembly Design (7 hours)

Date: July 19

- Designed box layout with airflow control using fans, valves, and seals.

- Incorporated Arduino sensor system for temperature and gas reading.

- Discussed pressure and gas flow constraints.

- Working on the 3d model

Day 7 – Poster Design & Presentation Prep (5 hours)

Date: July 20

- Designed informational poster for Calcify

showcasing diagrams, process flow, and environmental impact.

- Working on the 3d model

Day 8 – Testing & Iteration (8 hours)

Date: July 21

- Simulated air flow over Ca(OH)₂ sheets and observed modeled gas decrease.

- Measured hypothetical output vs untreated exhaust.

- Added feedback system for Ca(OH)₂ saturation detection.

- Working on the 3d model

Day 9 – Final Adjustments & Documentation (9 hours)

Date: July 22

- Finalized GitHub repository for Calcify

- Uploaded chemical reaction documentation, material sourcing spreadsheet, and system blueprints.

- Collected user feedback and summarized areas for improvement.

- Finalized the 3d model.

- Final testing and calibration documentation.

Summary Table

| Date | Tasks Completed | Hours |

|---|---|---|

| July 14 | Ideation & Problem Research | 8 h |

| July 15 | Chemical Research | 7 h |

| July 16 | Concept Design | 7 h |

| July 17 | Logistics & Material Sourcing | 7 h |

| July 18 | Lab Protocol Writing | 7 h |

| July 19 | System Assembly Planning | 7 h |

| July 20 | Poster and Presentation | 5 h |

| July 21 | Testing & Iteration | 8 h |

| July 22 | Final Touches & Documentation | 9 h |

| Total | 65 h |

Images:

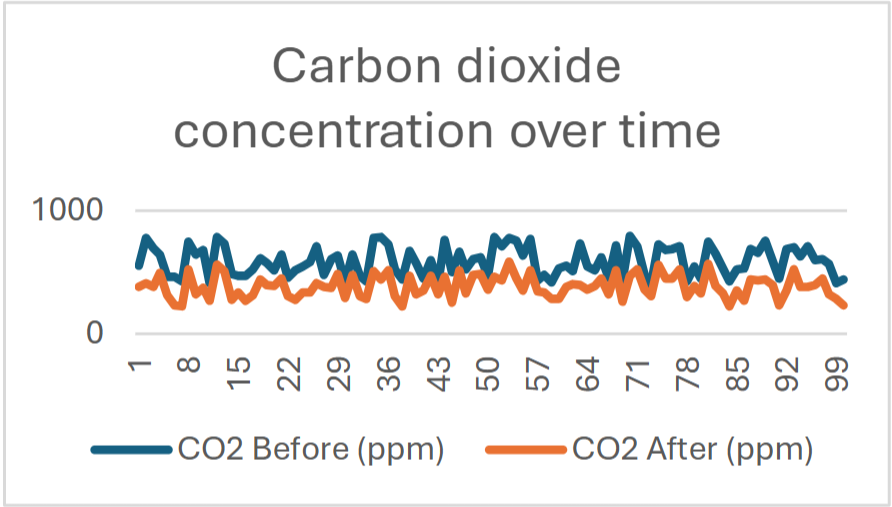

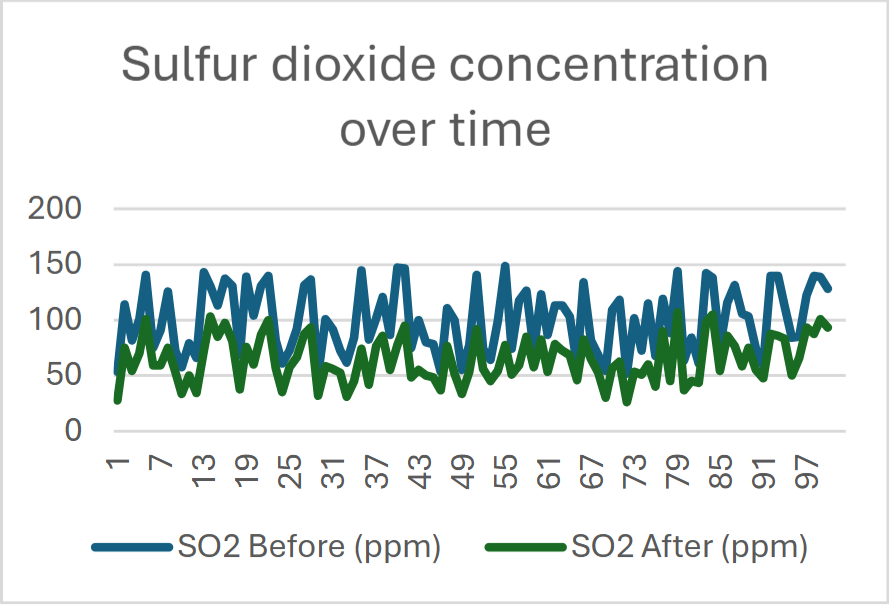

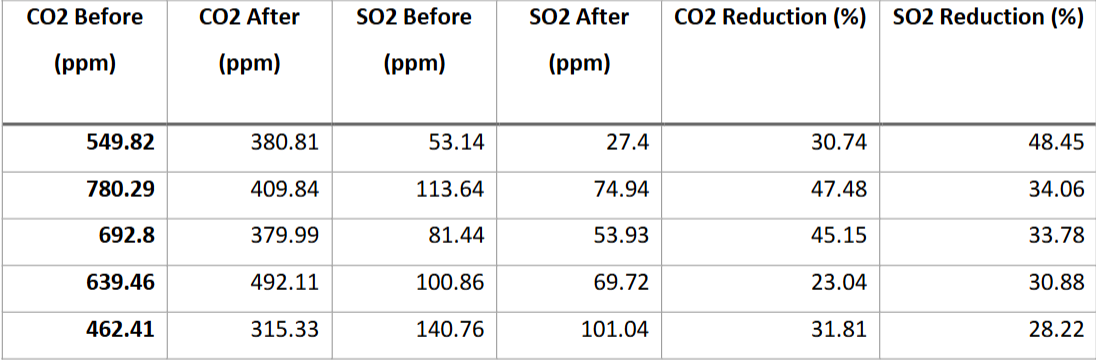

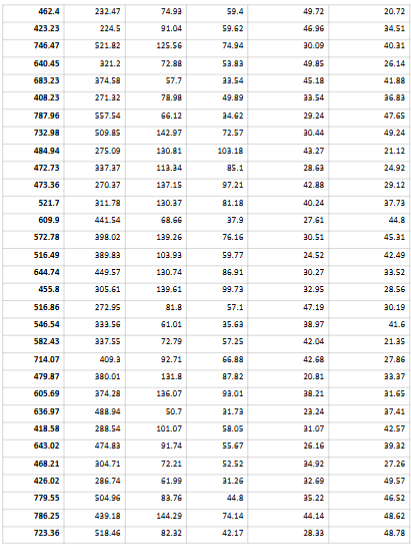

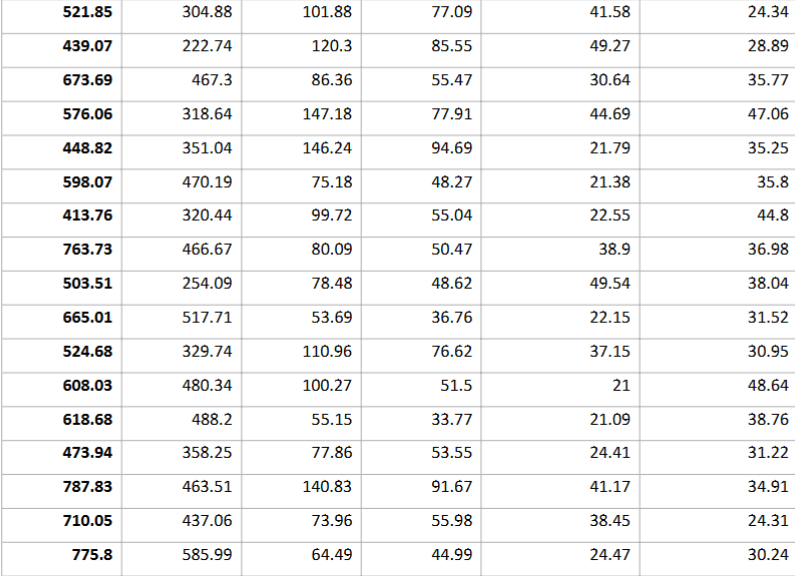

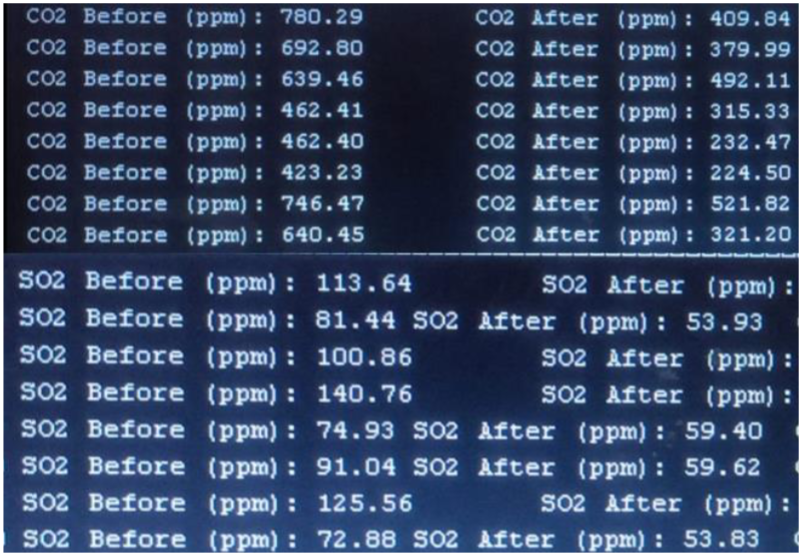

simulated sensors readings:

expected results: