Velocis

Ultra Fast CoreXY auto ejecting 3d Printer

Project Velocis

Author: Euwain Sheard

Description Ultra Fast CoreXY auto ejecting 3d Printer

Total time spent: *17h*

May 24 (Day 1): Started CADing and Part Sourcing

I started by looking at various parts and how they would fit into my project. This is what I decided on so far

| Part | Price |

|---|---|

| Phaetus RAPIDO HOTEND | $80 |

| Octopus Pro | $70 |

| Orbiter v2.5 | $50 |

I might change this later, but I like these parts

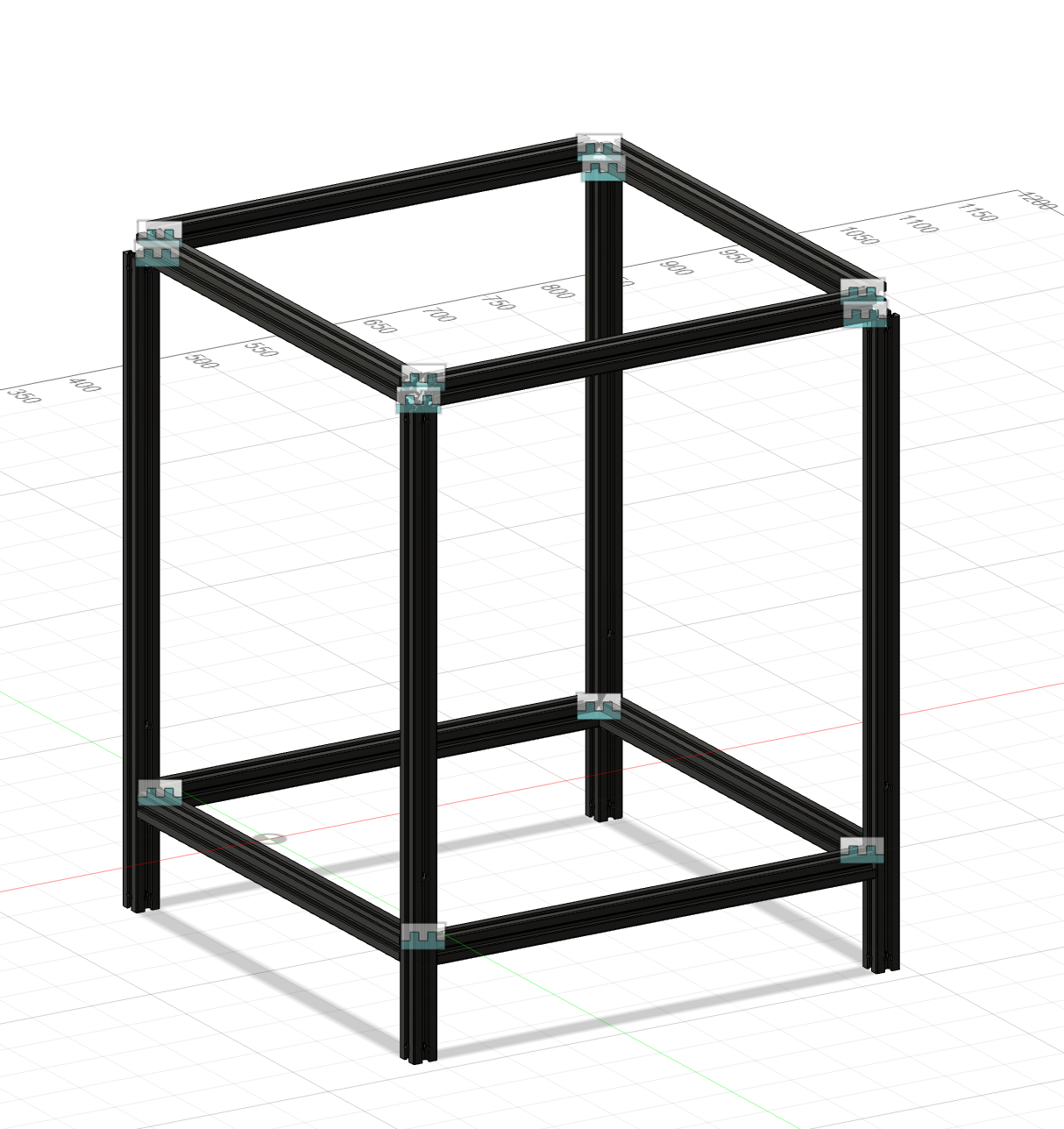

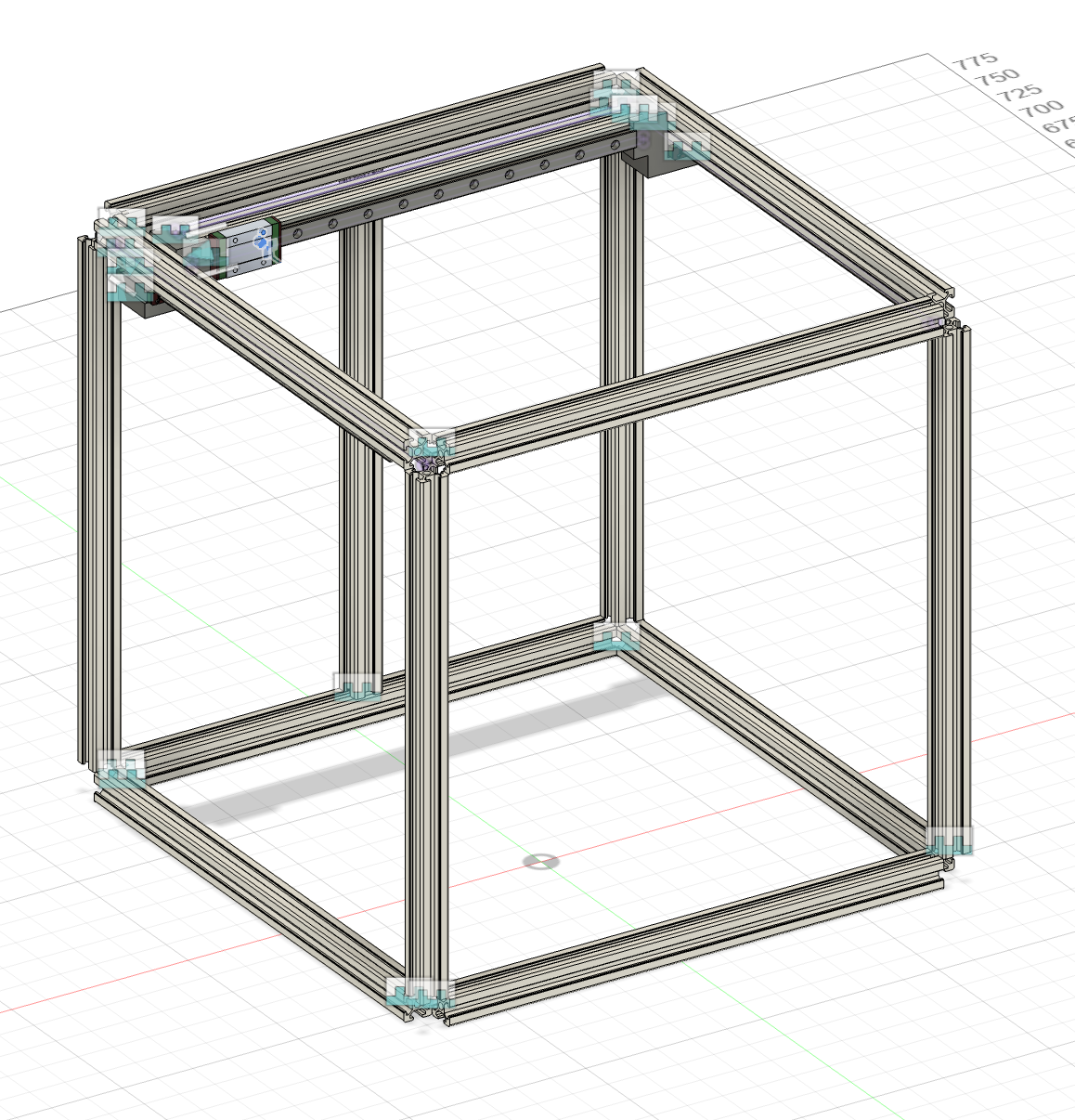

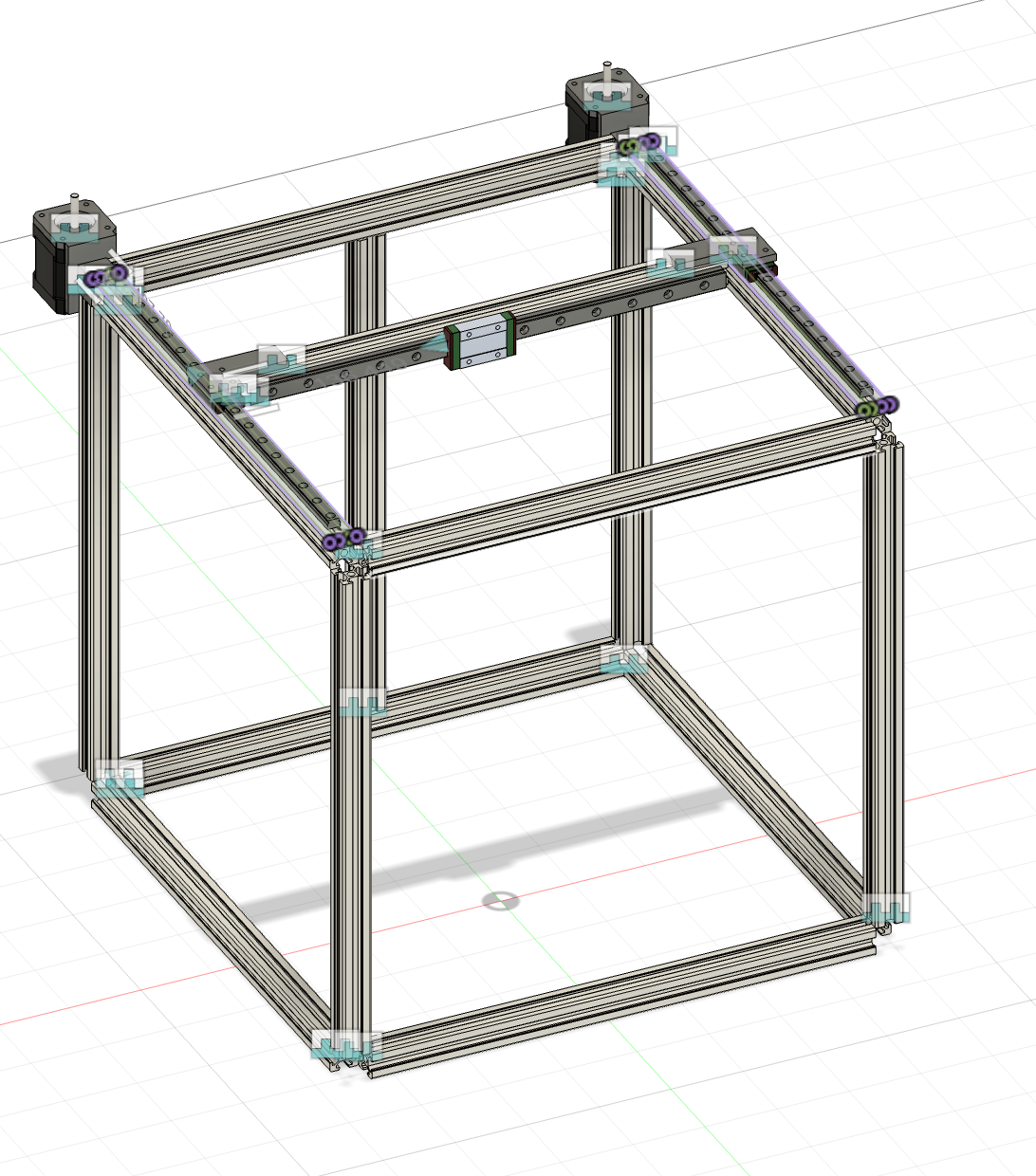

Now to Cad! I have taken inspiration from the Voron Trident for the design of the frame and triple lead screw z axis

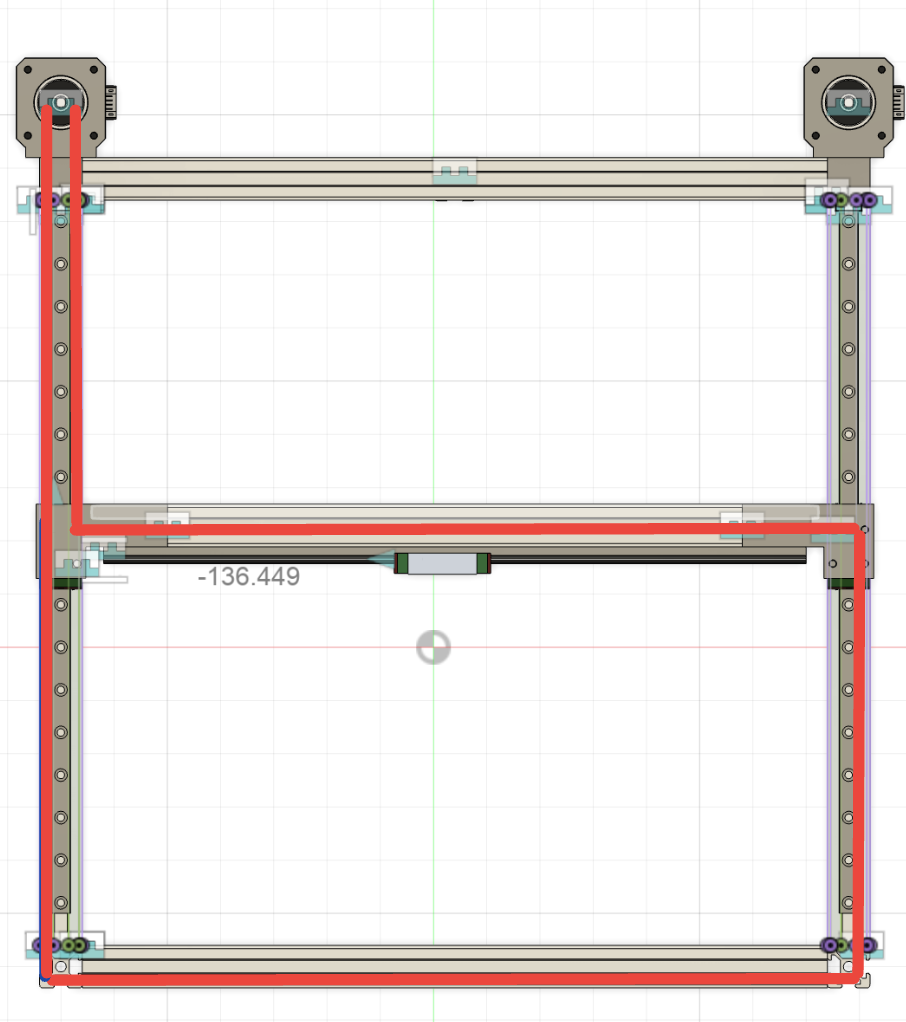

Picture of the cad

I am, however, having trouble with the extrusion files I found...

Time spent: 2h

Day 1 Part 2

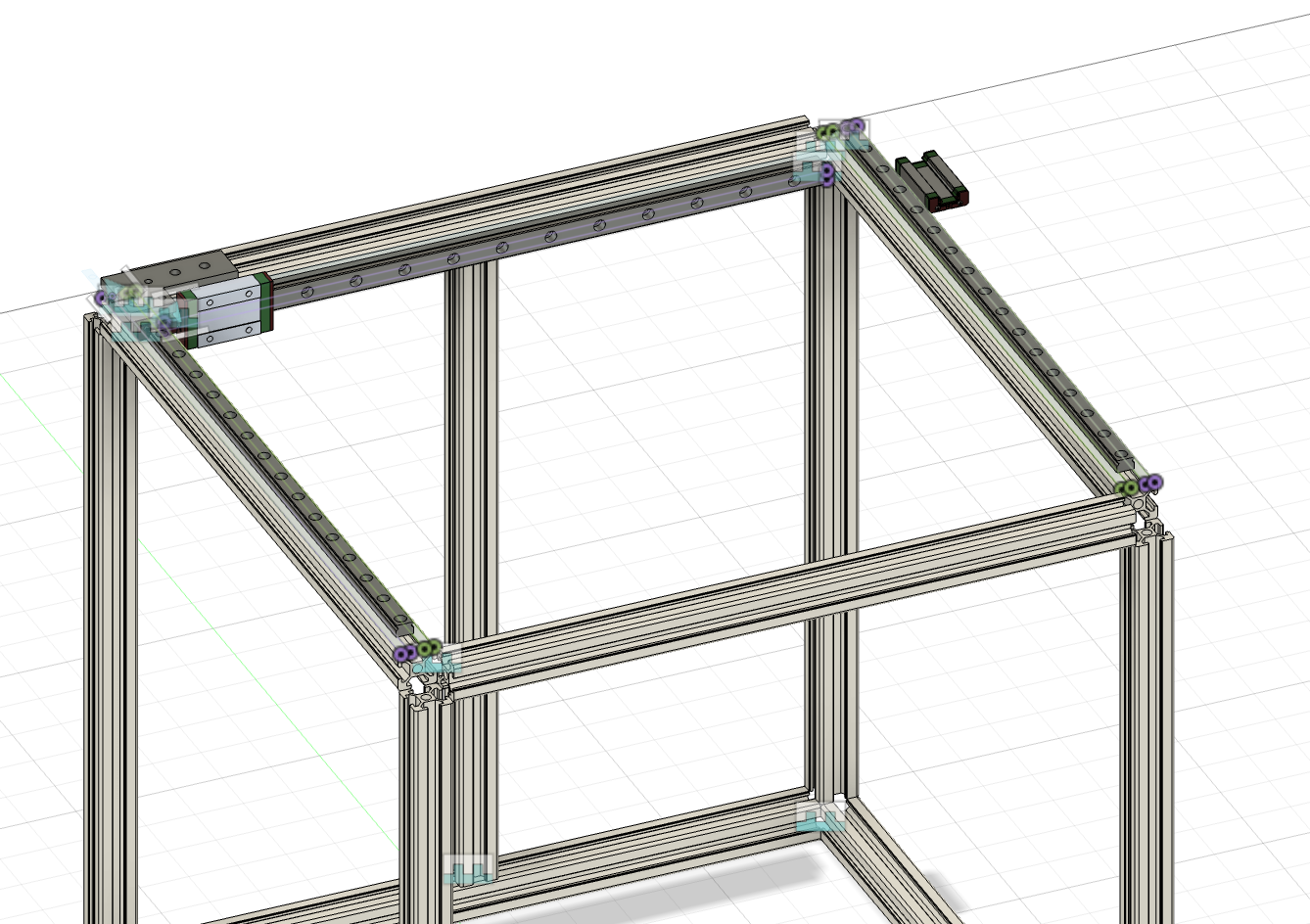

I worked on the Cad some more. I fixed the extrusion problems by uses these files instead. However this meant that I had to redesign the frame. When I redesigned the frame I decided to change some of the extrusion lengths. Now instead of 370, and 500, I shortened the extrusions to 350 and 450. I also modeled some of the x, and z gantry. I also organized some of the components, mainly the extrusions, into folders. I am going to use a mixture of Fusion 360's internal and external component options.

Updated Picture of Cad

Time spent: 1.5h

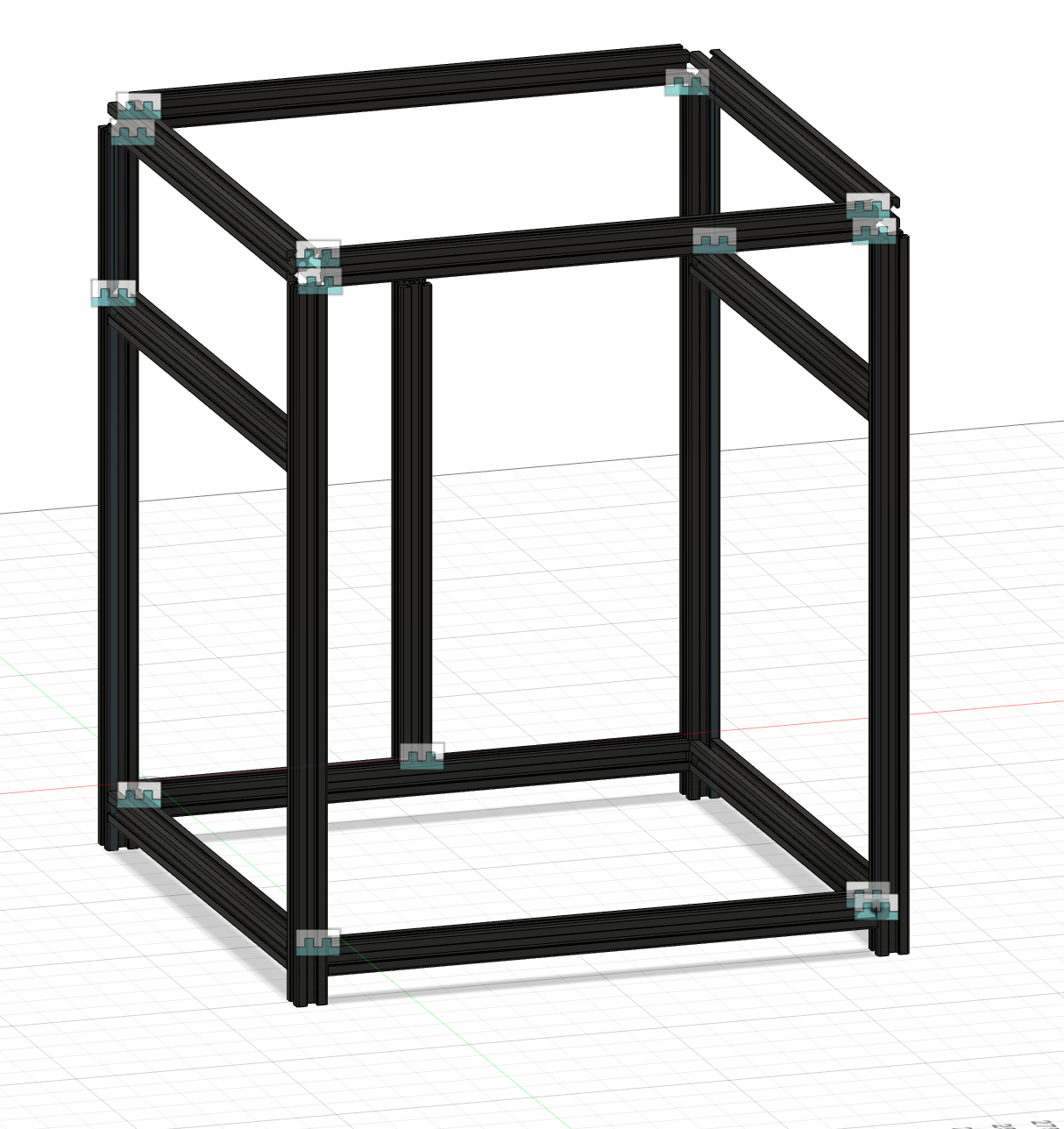

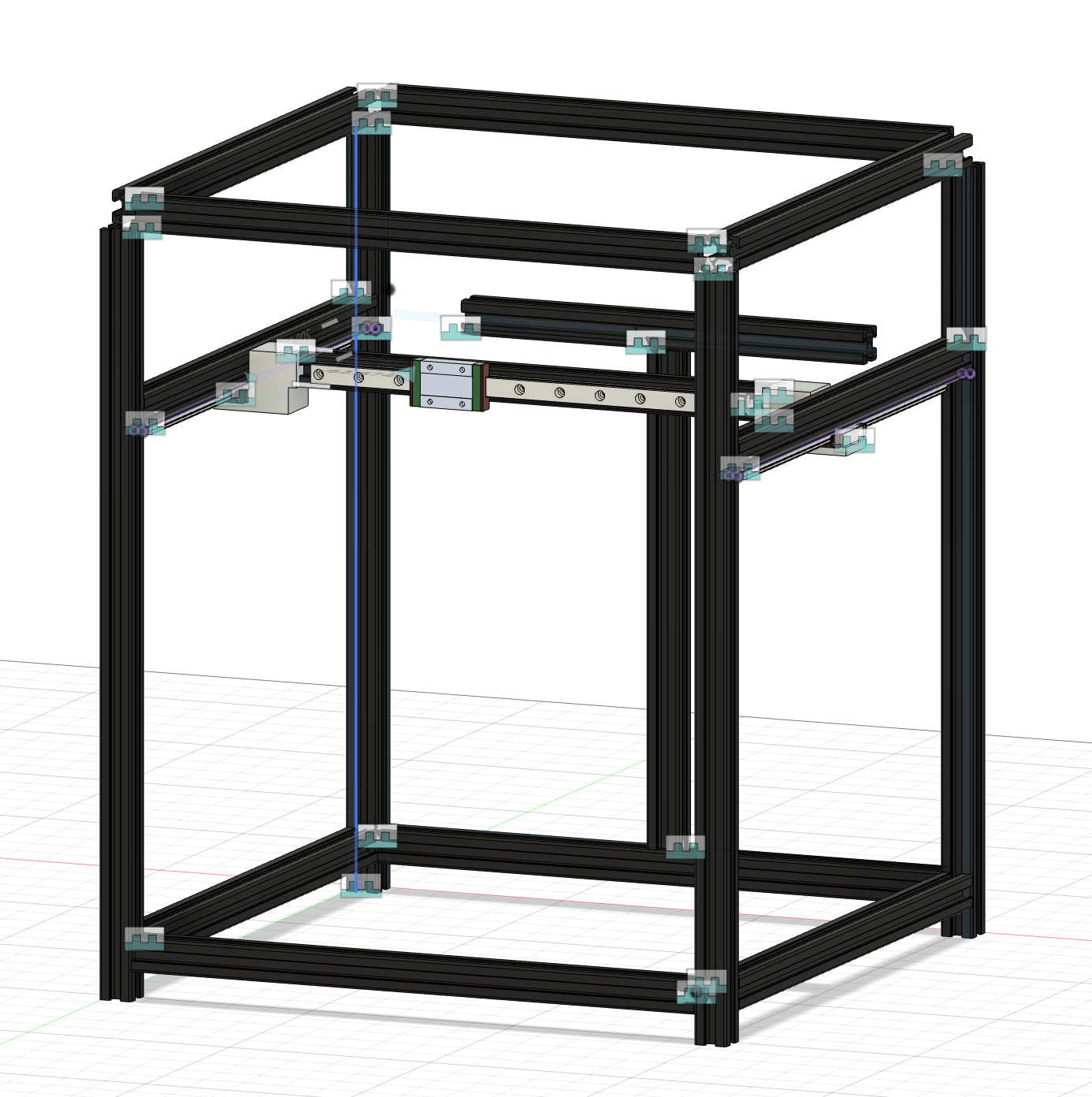

May 25 (Day 2): Cad

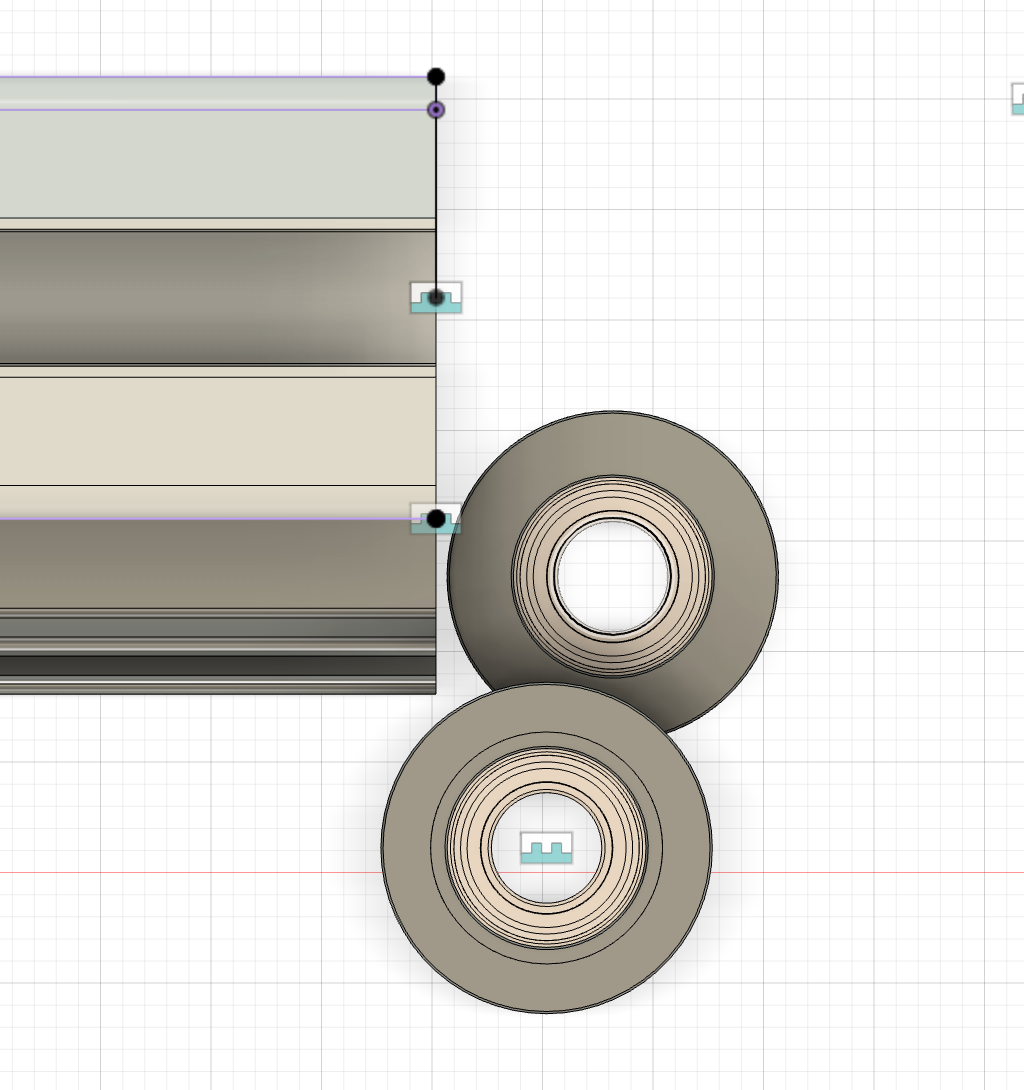

I started today by finishing CADing the basic frame, and looking at various linear rails. I found these on the Voron sourcing guide for my y axis, but I am going to shop around for better prices. I am going to attach the Linear rails on the bottom of the aluminum extrusions, so I can install a cable chain later.

I haven't CADed the linear rails yet, maybe I'll do that later today.

Picture of Cad

Time spent: 1.5h

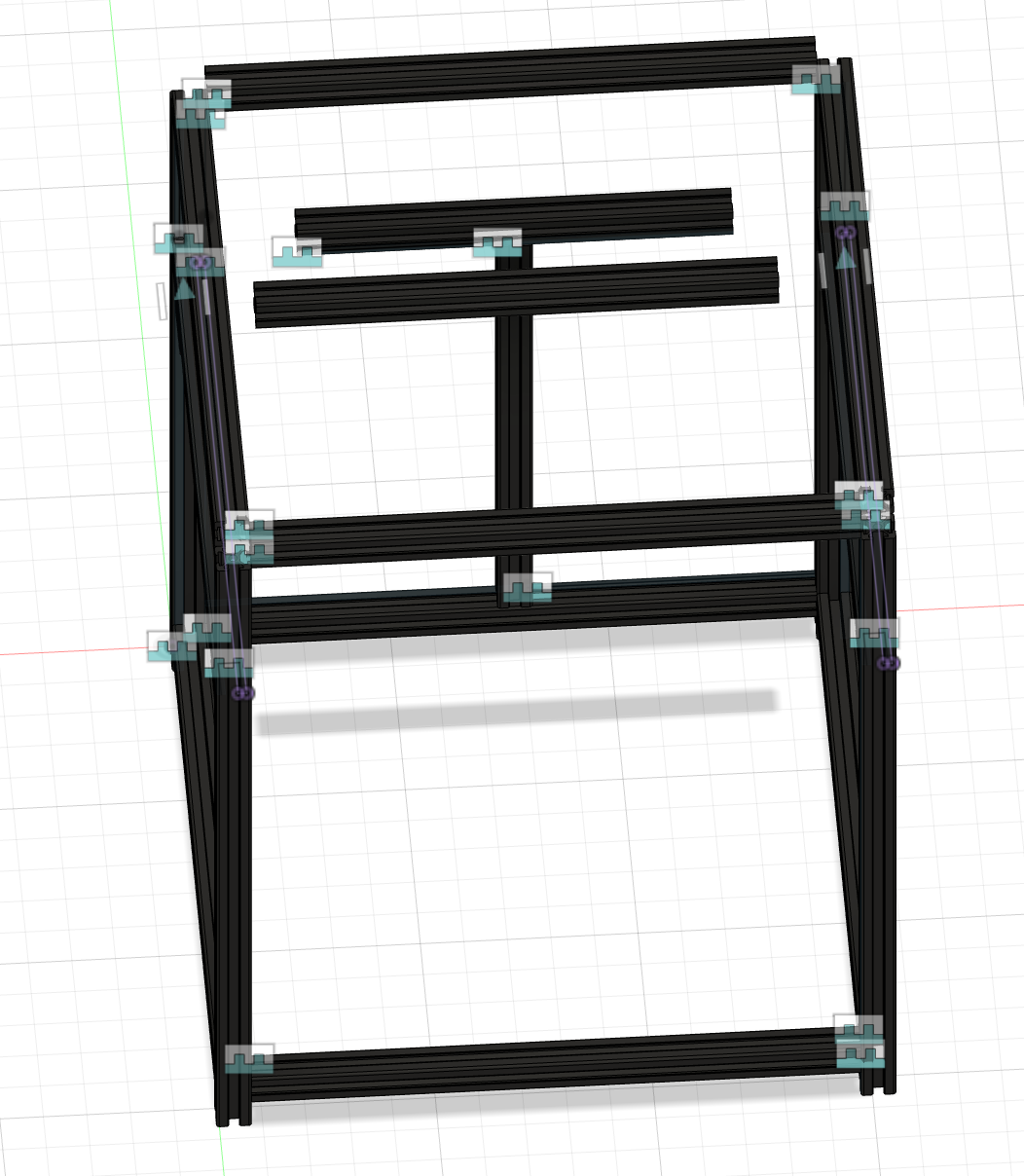

Day 2 Part 2: Cad

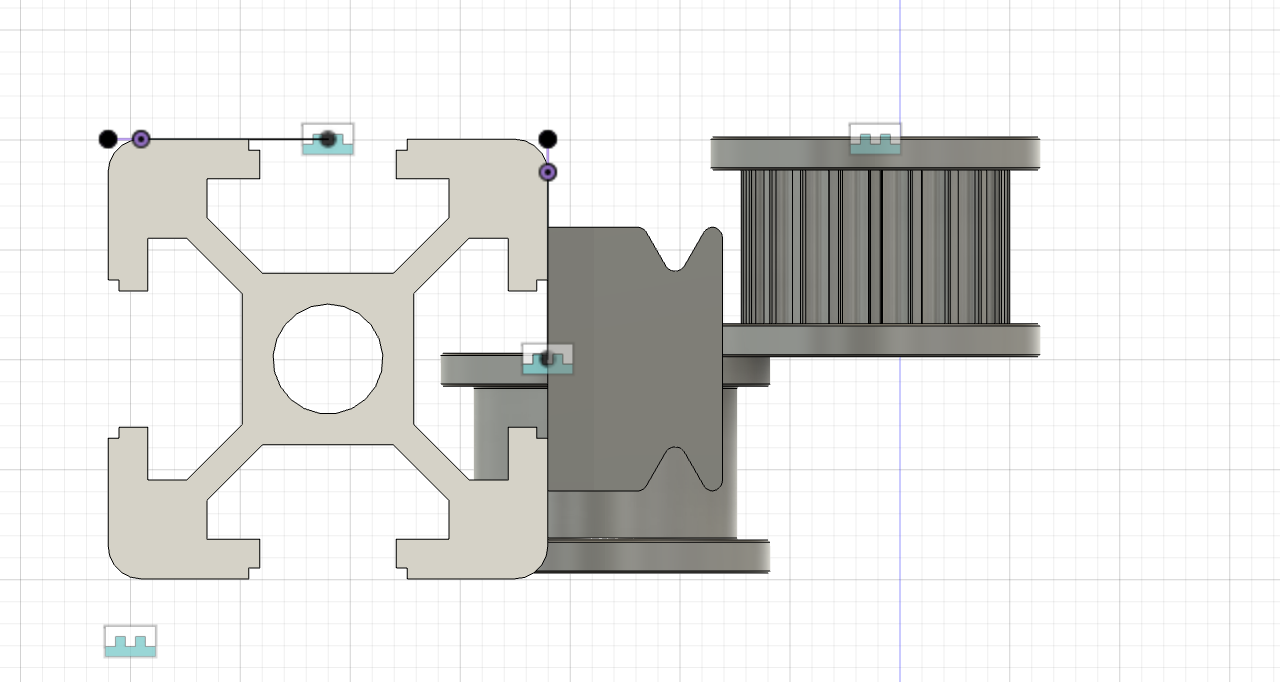

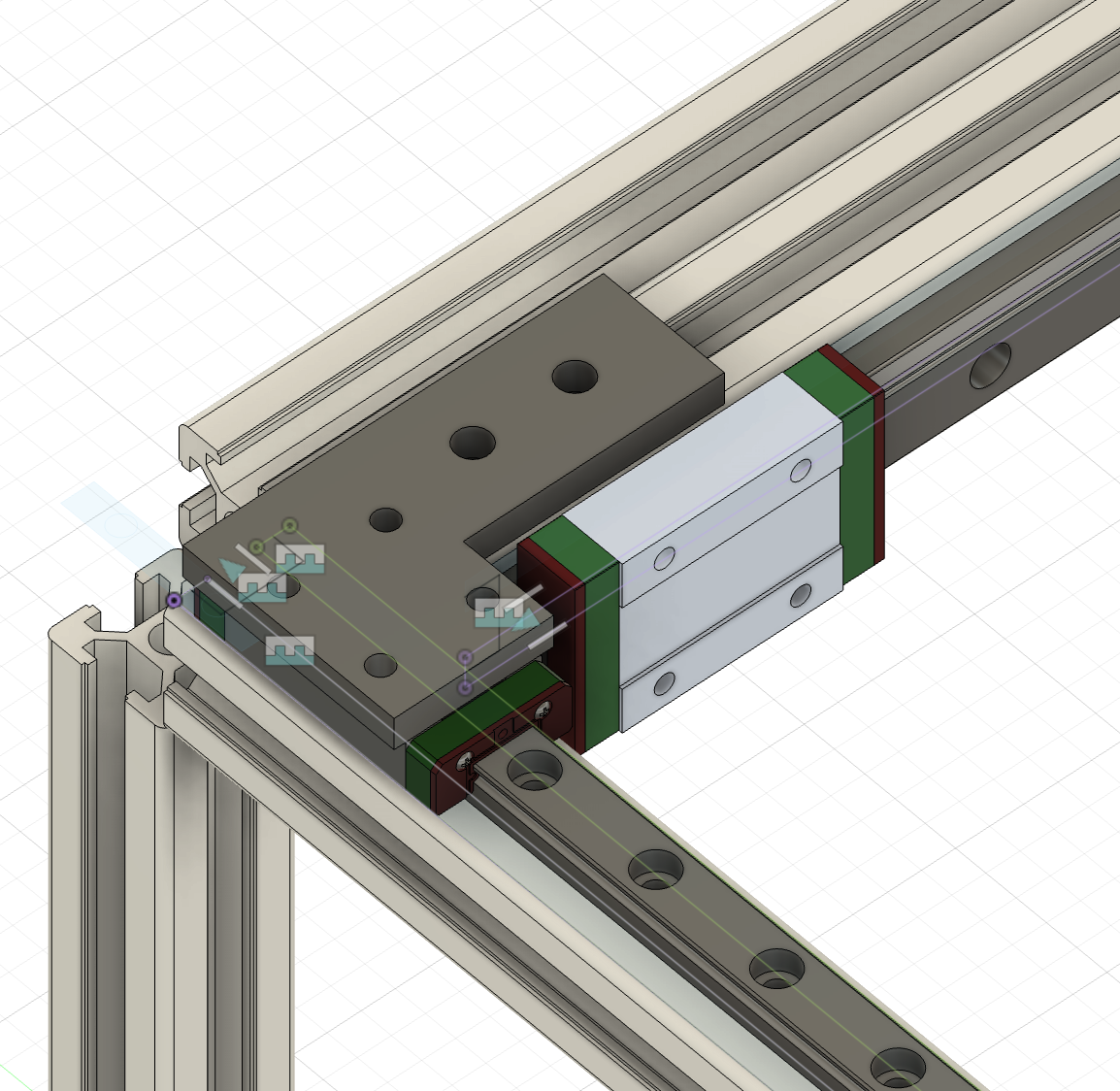

I started by finding models of the linear rails I am going to use. I am going with MGN9H for the y axis, which is what I am designing. I have no idea how this is all going to fit into the budget.

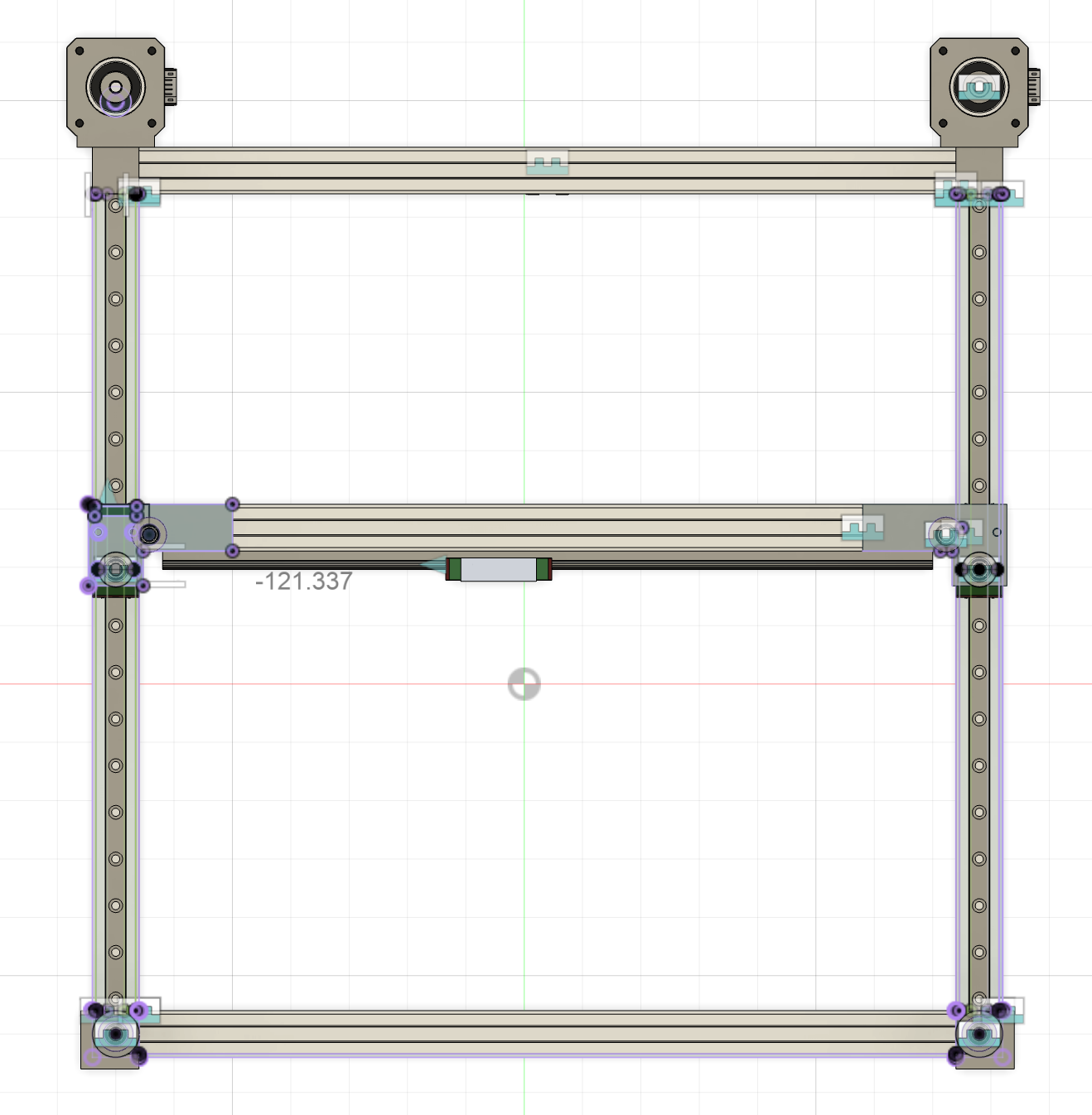

Then I started to CAD. I first modified the length of the files I found from 390 mm to 300 to use them in my design. Then I imported them and attached them to my frame with joints. Then I imported the carriages into the design and used a sliding joint to attach them to the rail. It took me a little time to figure out, but in the end I got it. I then imported another aluminum extrusion to work as my x axis.

Pictures of Cad

Added X axis extrusion

One of the linear rails

Time spent 1.5h

Day 3 (May 26): Tried to Cad and looked up corexy kinamatics

Today I started to Cad the connectors between the x axis gantry and the y axis linear rails, and completed this only to find out that one of the linear rails was not in the right place. Then I spend way to long only to not figure it out. This problem is really frustrating. I have looked at all the joints and sketches and what not, but couldn't find the error.

I decided to take a break and further my knowledge of corexy kinamatics. I have a basic understanding but want to learn more about it I found this really useful website that explains it.

I don't have any pictures of Cad for the moment, I am still working on the error 😔

Day 3 Part 2: Fixed error

I took a break for a bit to work on another project, after I came back to Fusion I had an idea to delete the sketch and look at the joint which was broken, and then undo it and fix the joint. This didn't work, but I was able to remake the sketch and that fixed it!.

Now I can finally work on connecting the extrusions!

I added an simple part to connect the extrusion to the linear rail, I still need to make the other one and add belt paths.

Pictures of Cad

Time spent 2h

Day 4 (May 27): Cad

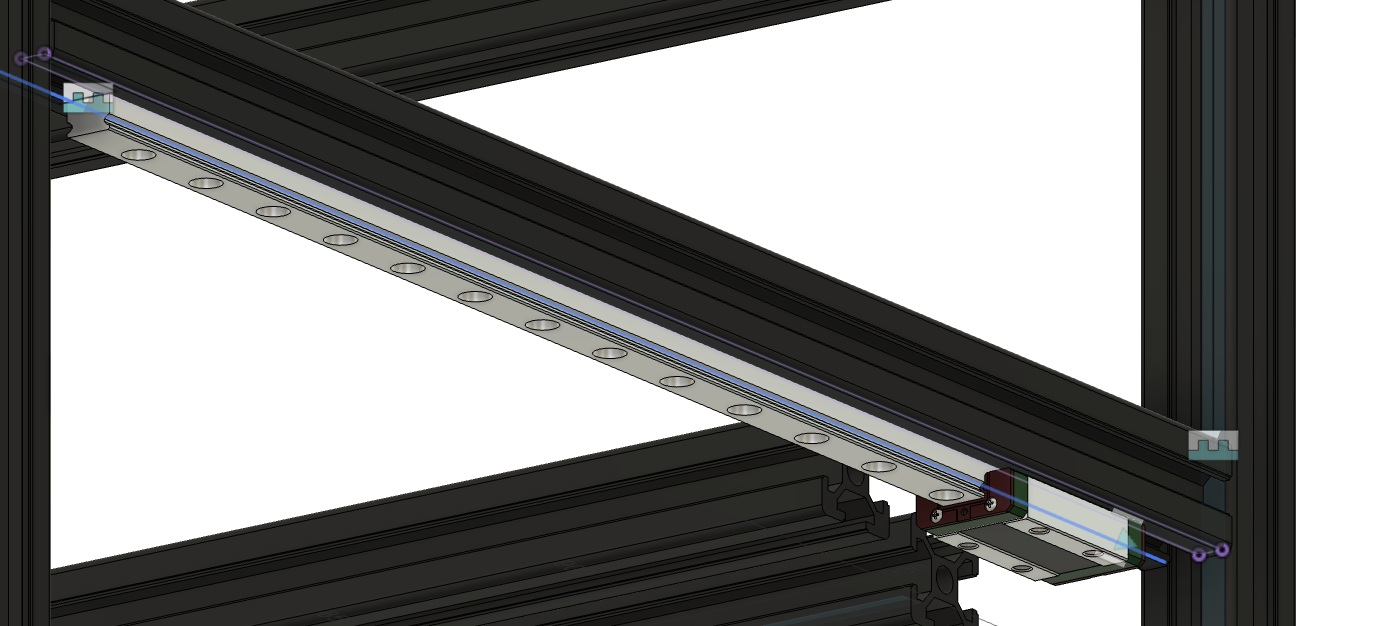

Today I started by mirroring the linear rail connector. I then started on the x axis linear rail. I connected the rail, but not the carriage. I will either do that later today or tomorrow.I also need to make the belt path and the idlers and pulleys.

I will upload photos of cad when I finish the x axis linear rail either later today or tomorrow.

Time spent 1.5h

Day 4 Part 2:

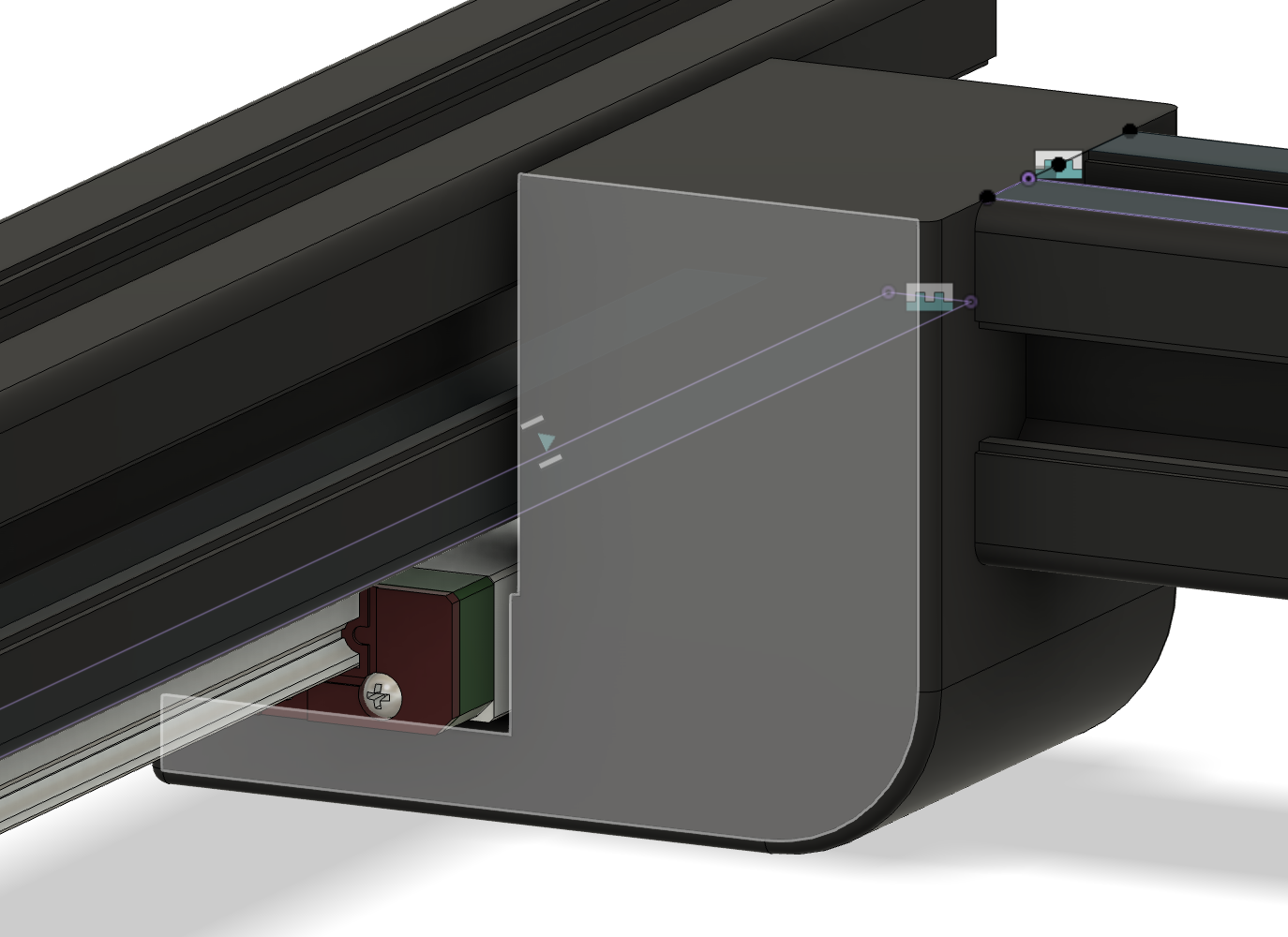

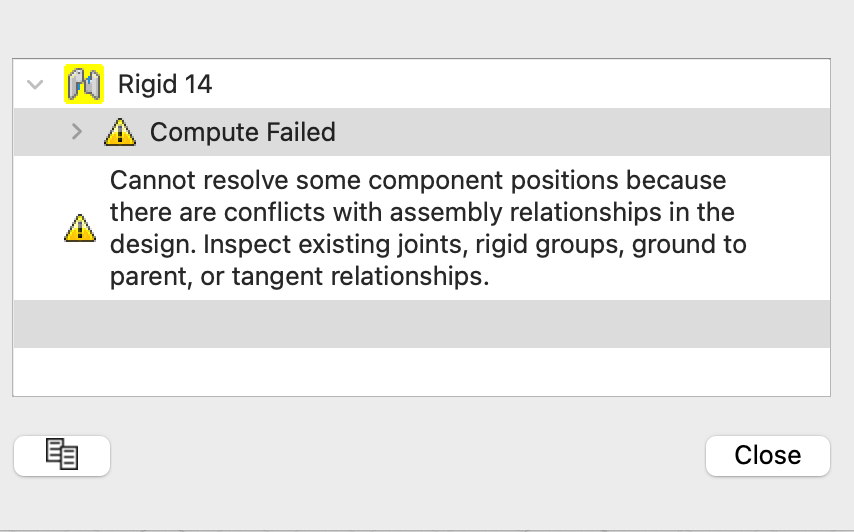

While making the gantry frame I encountered an error.

the joint was from one of the linear rails (I had previously connected the other one) to the x axis. T

I eventually fixed this error by removing one of the linear rail slider joints and it worked fine. Then I went in a search for my other linear rail. I have decided to a MGN12H linear rail.

Todo list for later

- Model Belt Path with Pulleys

- Model Z axis

- Model Hotend

- Find remaining parts

Pictures of CAD:

Time spent 1hr

Day 5 (May 29)

I was thinking about the 3d printer and realized I had some design flaws. I accidentally made the y axis 20 mm longer than the x axis which will make the corexy kinamatics extremely hard from the software perspective I also added a extrusion frame on top of the x axis, which is unnecessary and costly. I was also looking at my bom and it didn't line up, with my budget. I will have to work on that today, and fixing the CAD.

I worked on CAD for 40 minutes and almost got to where I left off. It goes so much faster know that I know what I am doing and already have the parts imported.

Pictures of CAD

I still need to change some things, but the design looks way more doable

Now for the BOM. I need to cut some costs because I am somewhere in the 500s. I think my origional goal of 600 mm/s might be a stretch unless I can get some of the other parts locally for cheaper.

For example my hotend, extuder, and mainboard together cost 200 dollars alone which means that I need to get everything else for 150 dollars, which dosen't check out.

Time spent 1hr

Day 5 Part 2

I worked on Cad some more and am at the point where is was at before I changed the model. I modeled a simple version of the linear rail connectors

Pictures of CAD

Time spent 1hr

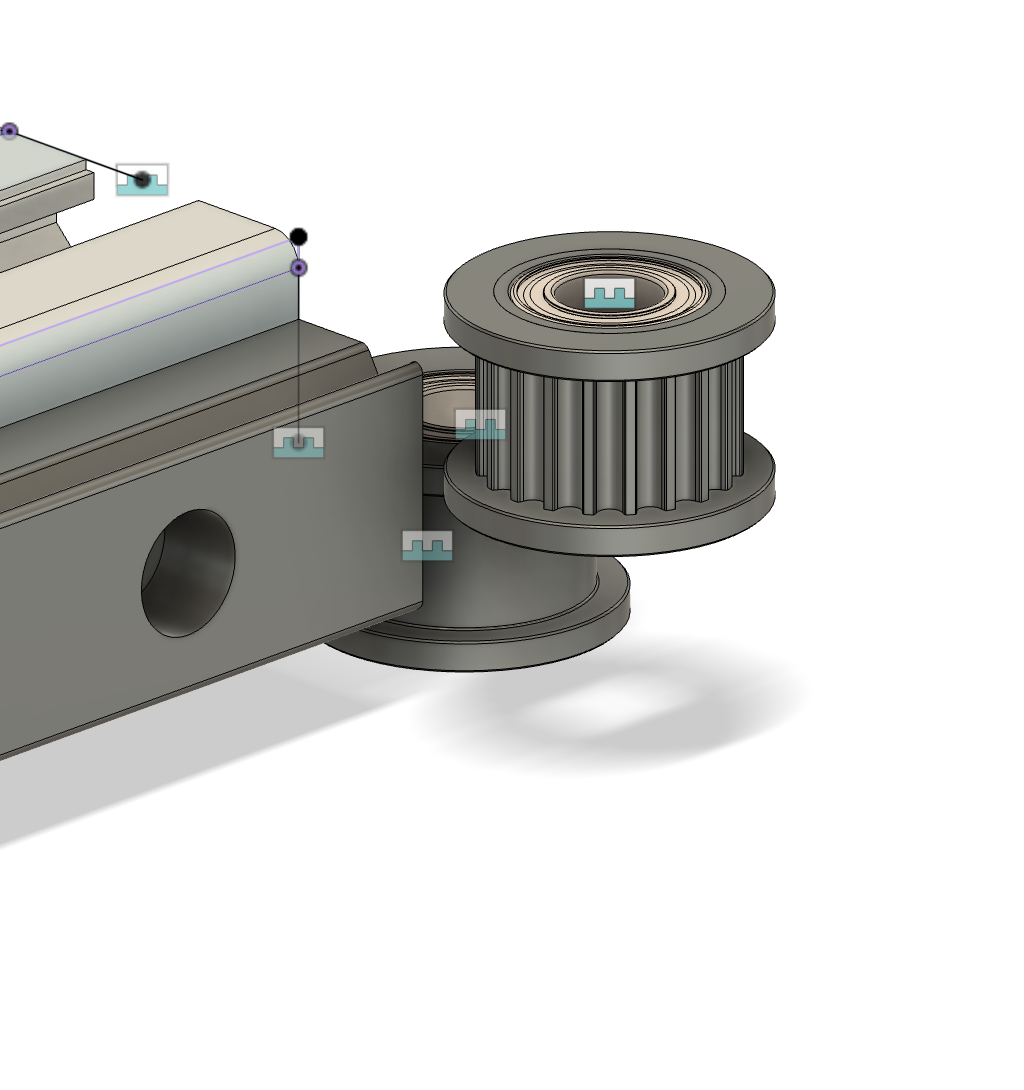

Day 6 (May 30): Started to Cad Belt Path

Today I started to model the belt path where the idlers will go.

Time Spent 0.5h

Day 6 Part 2:

I messed around with the position of the idlers and think I found the optimal position. I am designing the part in a different file and will just import into the main design

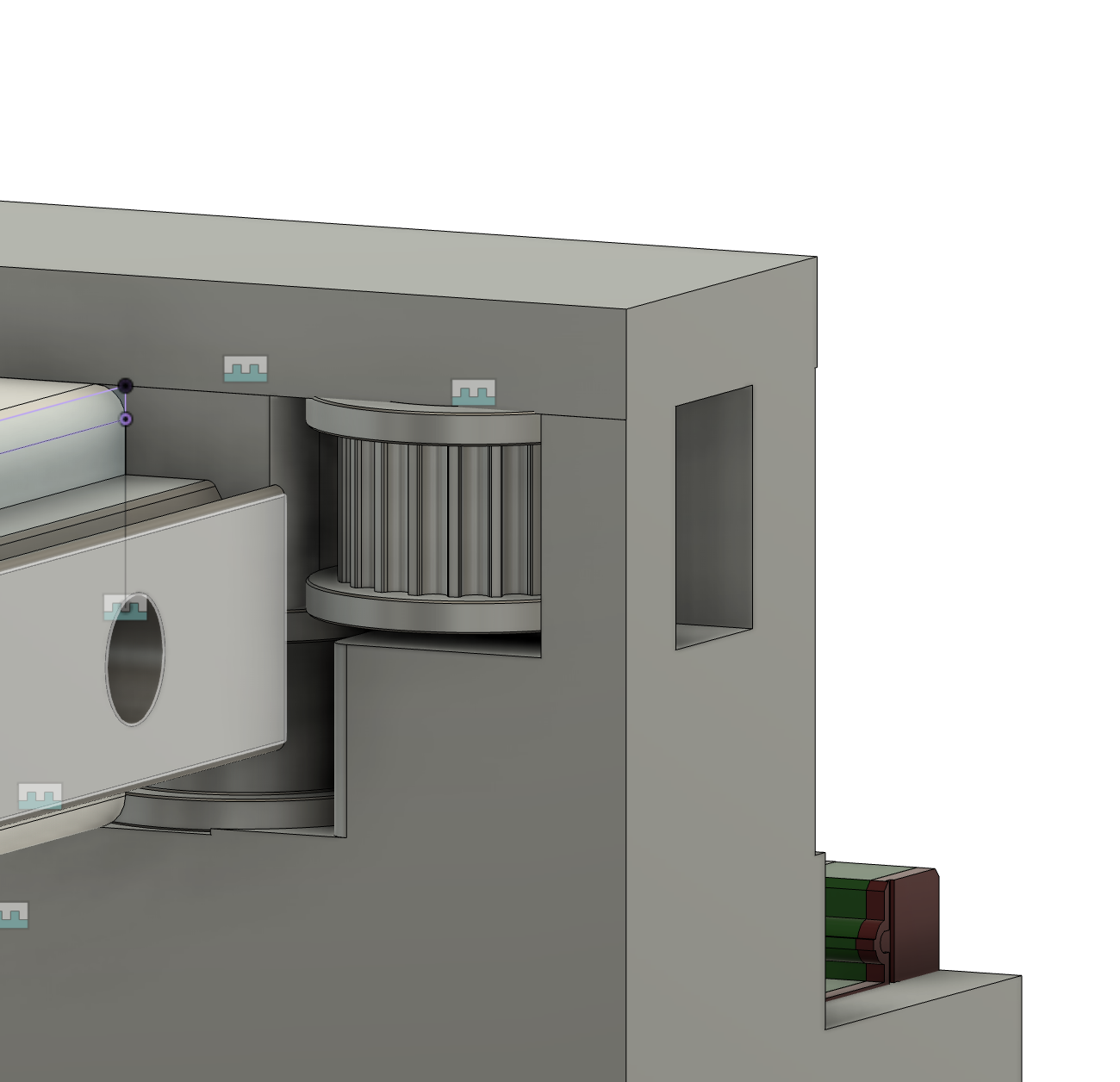

Pictures of Cad

Time Spent 1h

Day 6 Part 3: Finished Cad Mockup of belt path

I finished a belt path mockup for the right side of the x axis. I now need to modify it a little bit and then add it to the main design. I was experimenting with different positions, but I think I found the optimal one. I also need to switch the belts and add it to the left side

Pictures of CAD

I was also looking at the budget. I really need to strip some of the more expensive parts to cheaper alternatives.

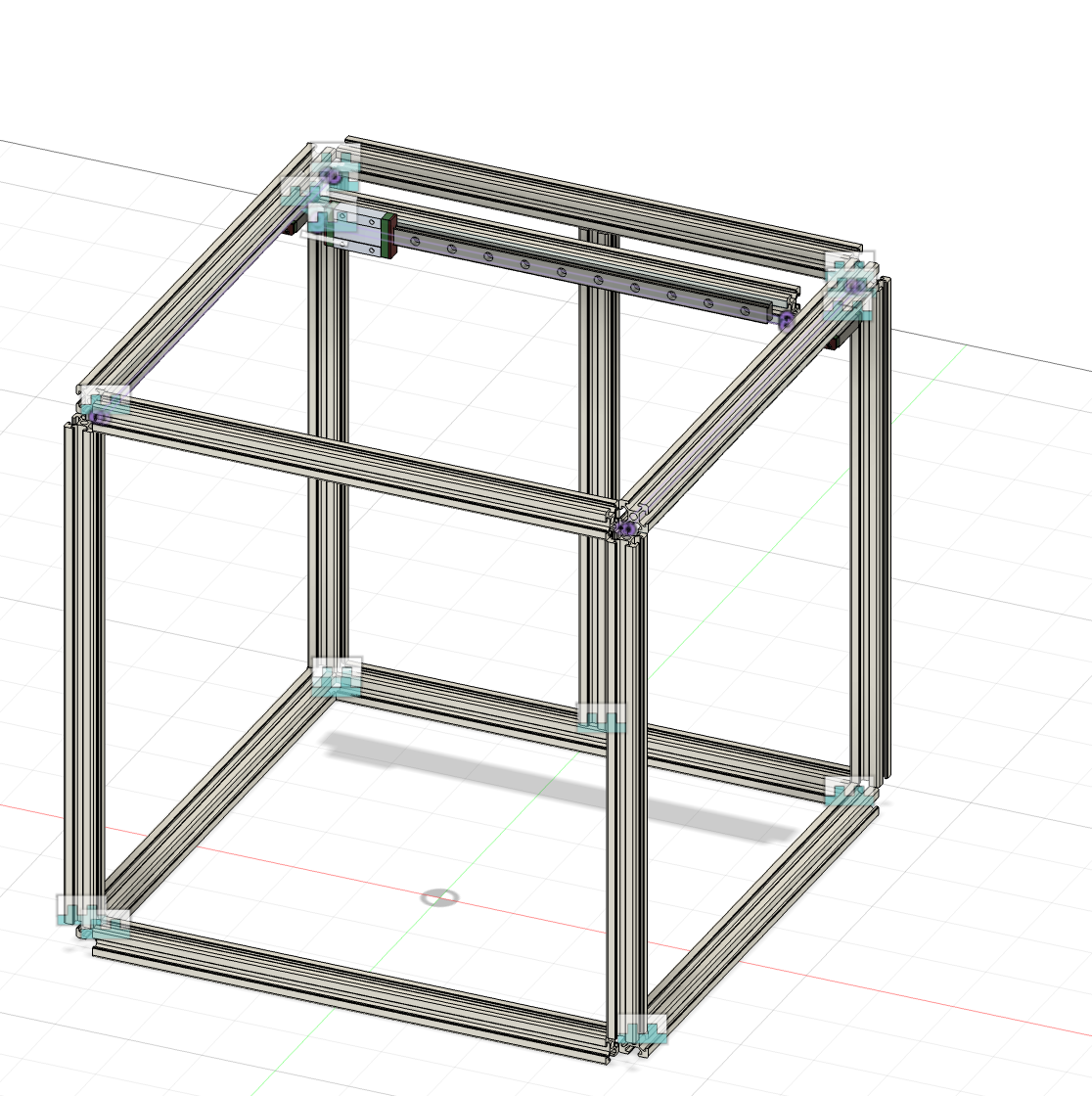

Day 7 (June 7): Modified design continued CAD

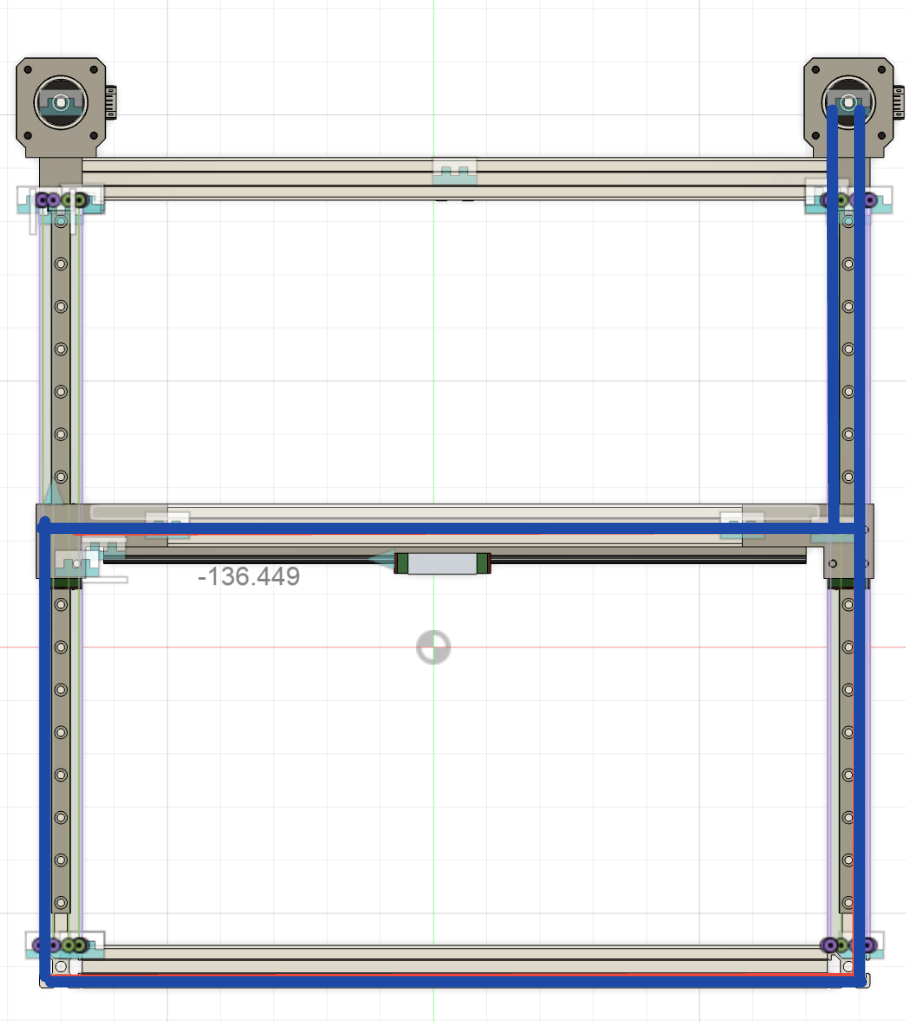

I have realized with the given budget, my expectation is too high. I am going to try to make the printer reasonably fast, but it probably wont hit the 600 mm/s I was hoping for. I have decided to move the linear rails for the y axis to the top of the gantry for simplicity of making the belt path. I have started to model these, but due to limited time I will finish them later.

Pictures of Cad

This is the new design I am going to do

Linear Rail connector so far!

Time Spent 1hr

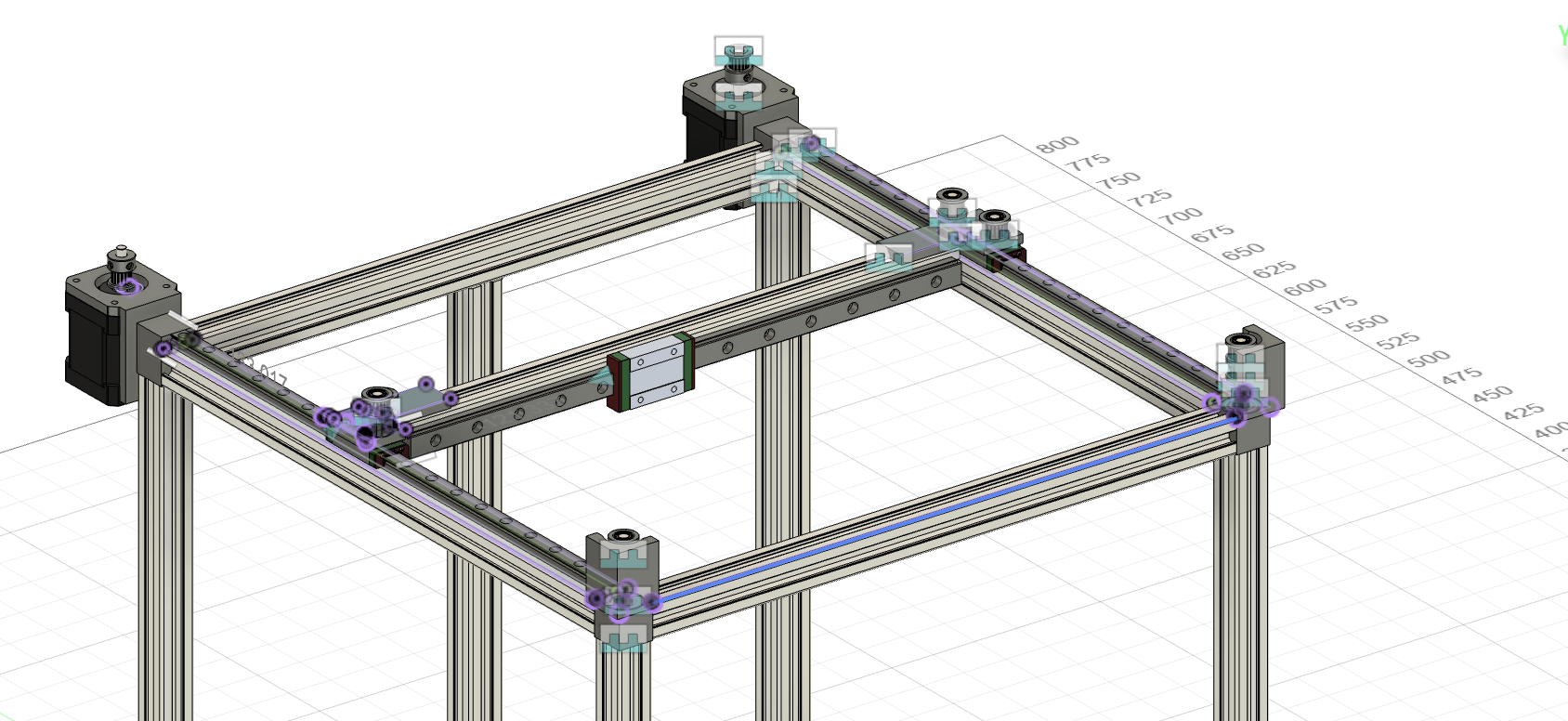

Day 7 Part 2: Added Stepper Motors

I added the CAD files for the stepper motors, and made motor mounts that double as corner cubes. I am going to go with NEMA 17 48mm 56 N. I found these on the voron sourcing guide. Stepper Motor

I also made a mockup of the 2 belt paths for reference

Pictures of CAD

Time Spent 1.5hr

Day 8 (June 8): Cad and BOM

I started today by spending some time finishing the belt path. I am excited because this is one of the parts I felt intimidated by. I decided to route the belts on top of the printer, for simplicity in design. I might redesign some of the components later for ascetics. I am going to work on the hotend and z axis next.

I also started my BOM. I might change some of the vendors later, but this is what I have found and modeled so far.

Pictures of CAD

Time Spent 2.5hr