Soldery

A USB-C PD powered PCB soldering hotplate.

Soldery

2025-06-08

Why?

I really want to be able to solder boards faster, I currently only have a soldering iron, which works for most SMD components, but barely(?) works for chips like the RP2040, and not at all for any BGA chips.

I looked at buying a hotplate online (boring!), and all the ones I could find were: - too small for the size of my boards - too expensive

Naturally, I did a Google search to see if there were any existing DIY hotplates I could take inspiration from: - DIY-USB-PD-Powered-MCH-Automatic-Reflow-Hotplate-O which used USBC-PD and a Metal Ceramic Heater. - Tim's Hot Palate using wall AC and a 300W PTC heating element.

After some deliberation, I came up with a plan: - Make my own heating element using an aluminium PCB (so it can be as big as I want!) - Make a seperate control board using an rp2040 - Make it USB-PD powered for ultimate portability

Hotplate

I need to design the hotplate somewhat quickly because it will take a long time to ship, and if it doesn't work I need to be able to make another revision quickly.

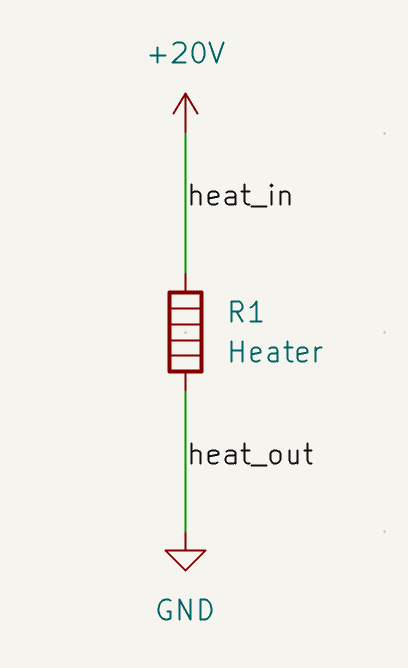

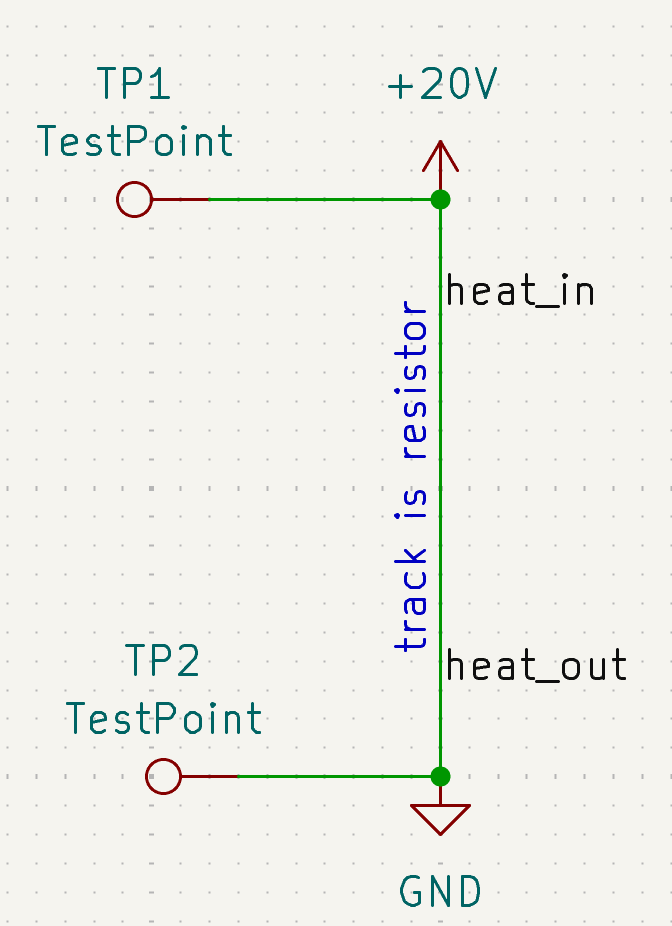

I created a new KiCAD project, and created a schematic for reference.

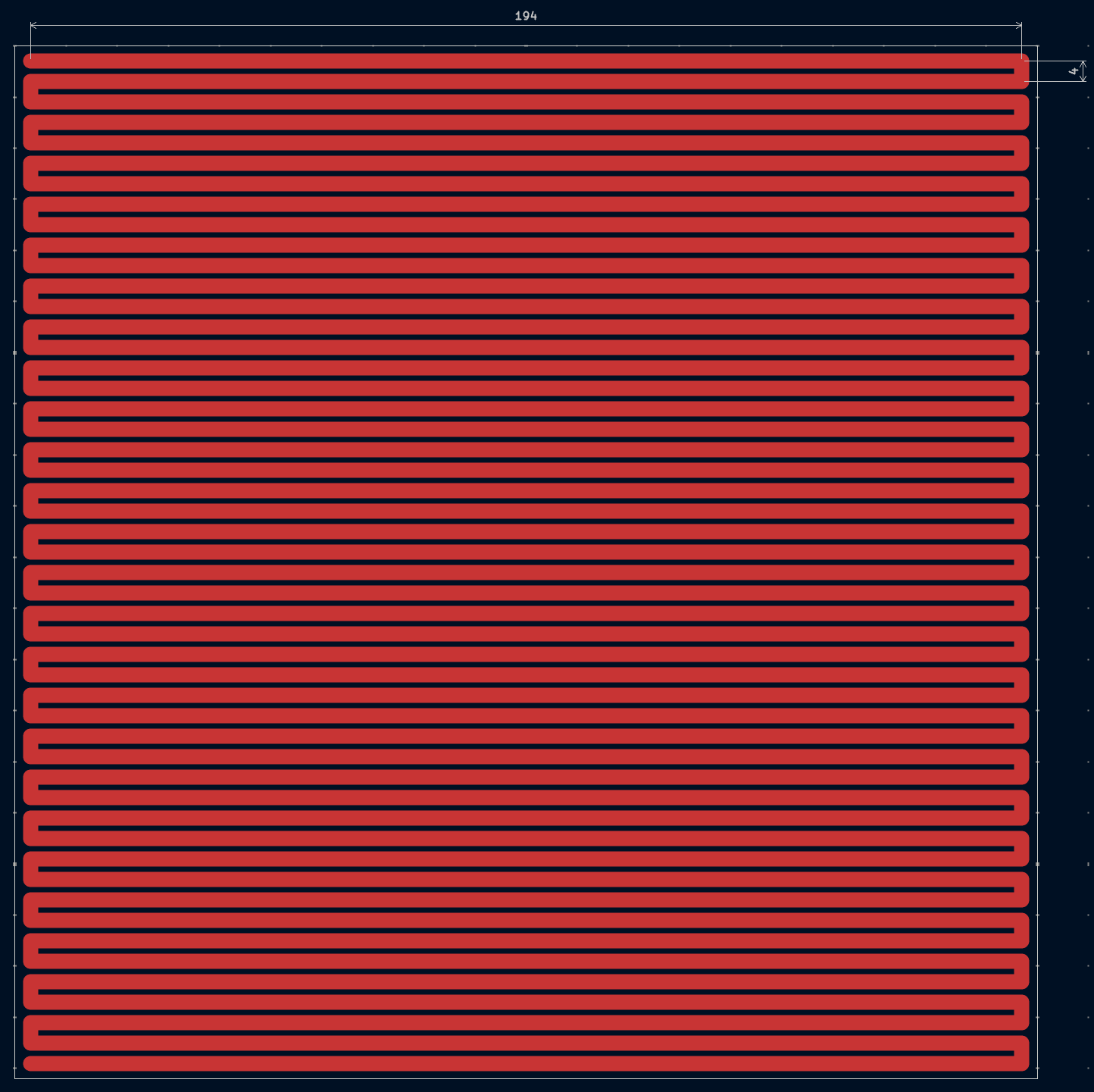

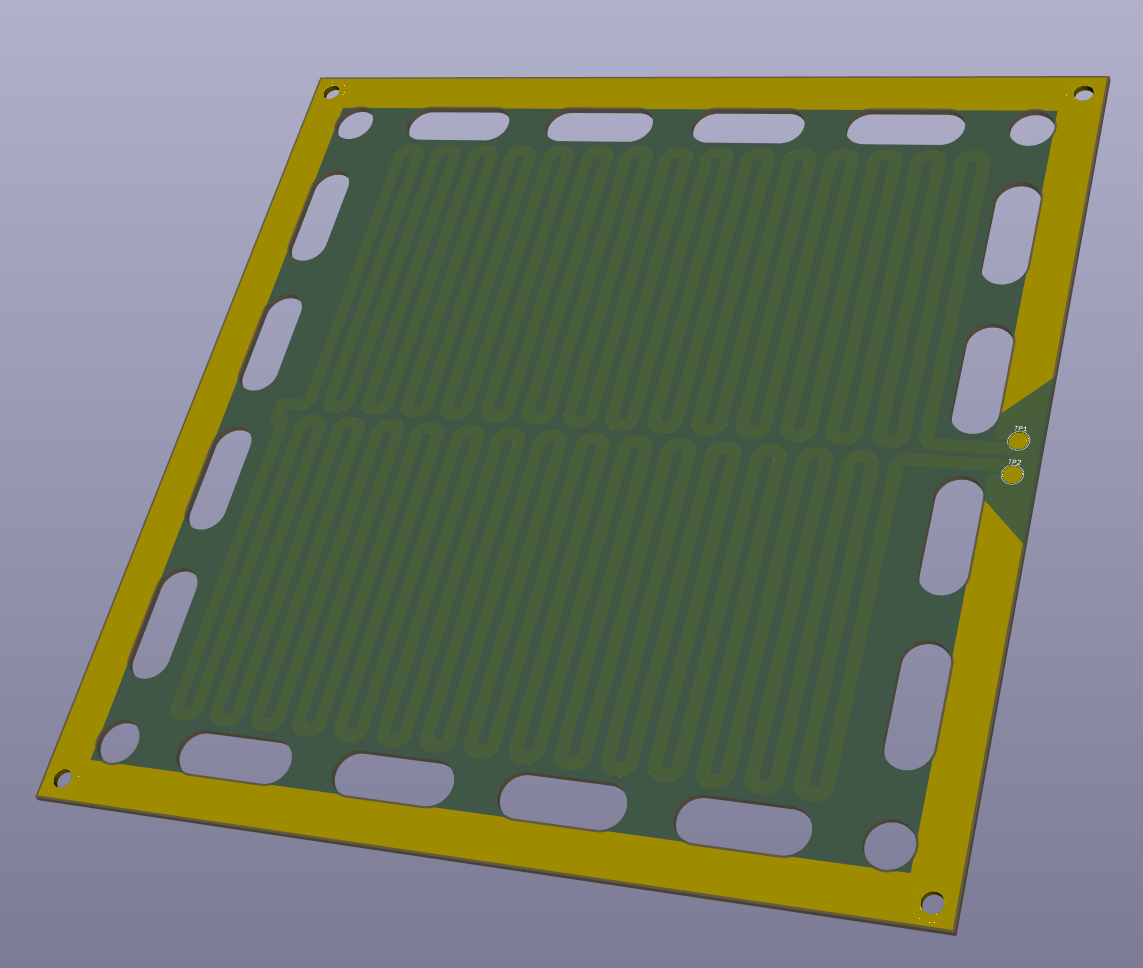

I created a new 200x200mm PCB with a 3mm track width, and 50 horizontal lines.

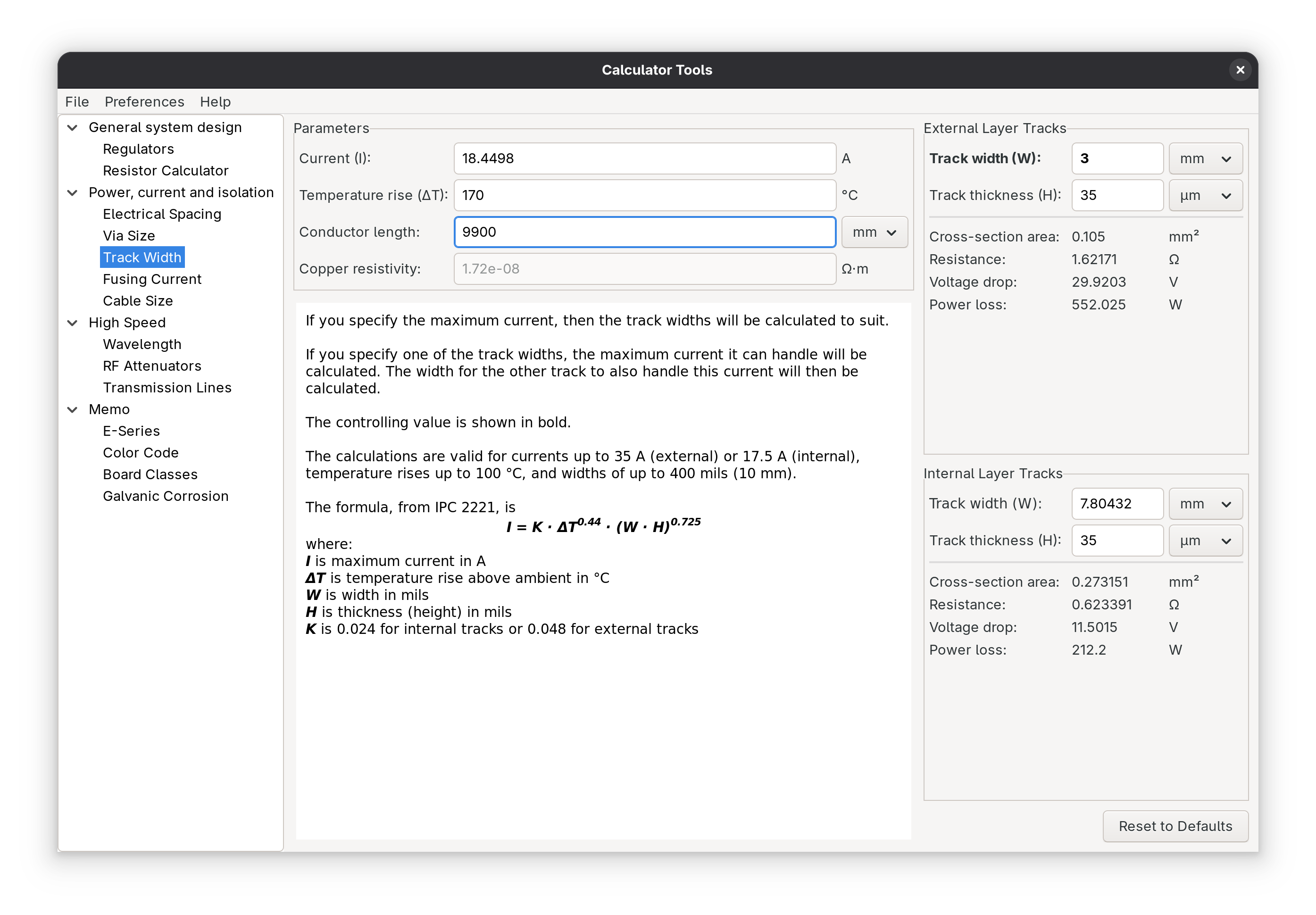

And I used the PCB calculator to find out the resistance.

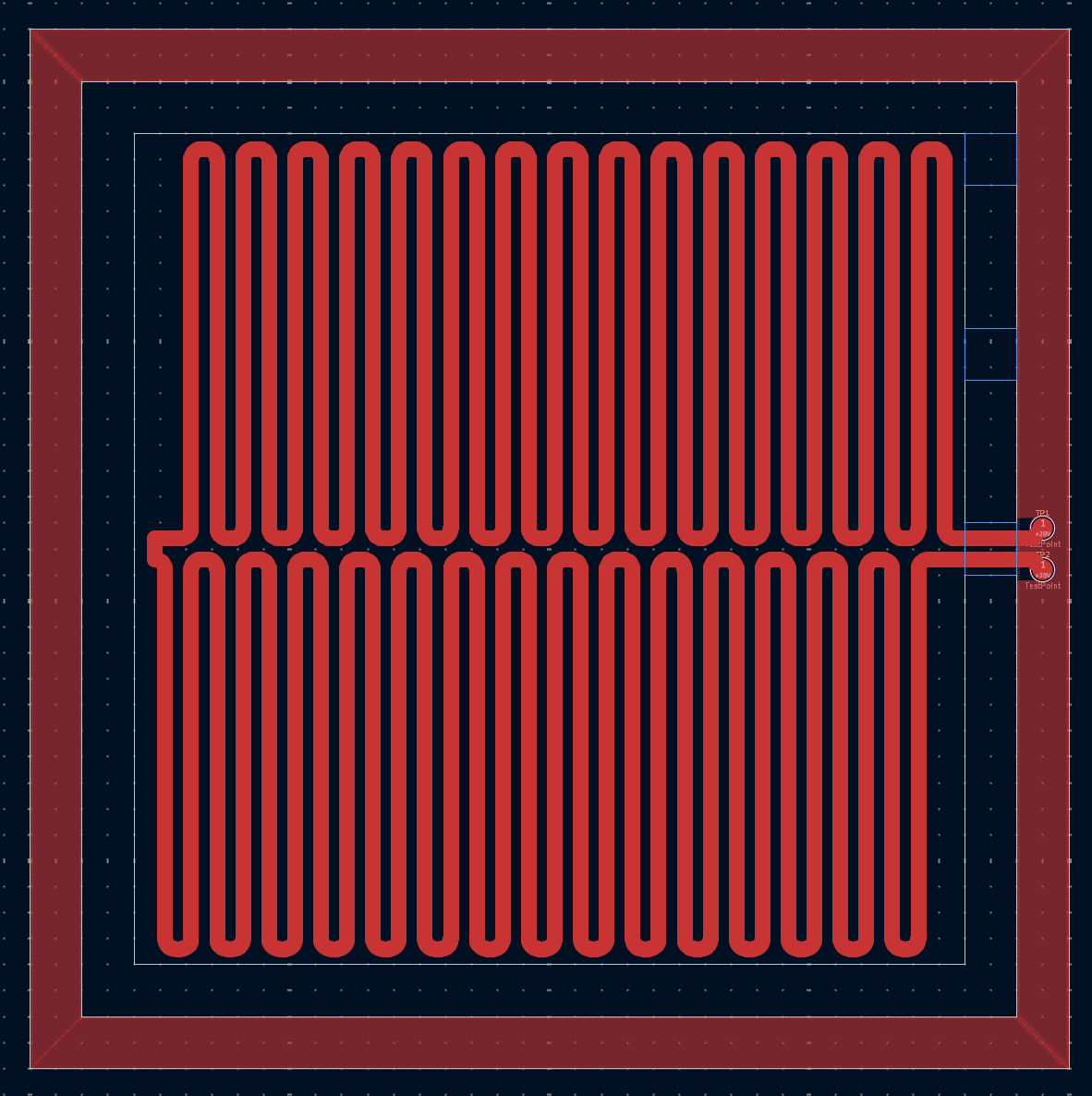

I realised that a PCB with only traces was a bad idea due to dificulty mounting and soldering to, so I decided on an alternative design inspired by ref2.

This means an outer ring of exposed copper, and an inner square of traces, connected in a few points to the outer ring.

This means that I can place all the mounting points on the outer ring, at low temperature, and still have a high-temperature inner square to reflow with.

I used KiCAD's Tune lenghth of a single track

function to generate the curves this time, instead of doing it manually like the previous design.

And a new schematic, to give my traces a single net to stop DRC from trying to keep + and - seperate.

This is currently only somewhat half-finished, but it is pretty late right now, so I will continue this tommorrow.

Reference:

- 1 https://www.youtube.com/watch?v=dy9NutXl2OY

- 2 https://www.youtube.com/watch?v=ZChSbpBbrt4

- 3 https://www.youtube.com/watch?v=fbBXPeC-FPQ

- 4 https://www.youtube.com/watch?v=kcmpGbR6xZc

2025-06-09

Hotplate

I finished a first draft of the hotplate design!

However, bad news. I've had to put a pause on this project due to safety concerns over making my own resistive heater without a proper workshop.

For now, I'll be working on my open-rgbw-lightwall project, but if/when I can, I'll return to this in the future.