Smxy 3d

Total Time Spent: 77 Hours

June 12th : Project Ideation and Sketching

- Started planning the overall design and purpose of the 3D printer on paper.

- Researched core features to be included in a high-speed and professional printer.

- Noted ideas around rigidity, performance, and ease of upgrade.

- Finalized goals like: strong frame, high speed, and high print quality.

Key Features Finalized:

- Core-XY motion system

- MGN12 Linear Rails

- Klipper Compatibility

- 310×310×310 Build Volume

- Dual Z-Axis

- Bowden Extruder

- Octopus v1.1 Mainboard

- 4040 Aluminum Frame for stability

Time Spent: 4 Hours

June 13th : Feature Research and Frame Design

I learn and study about various printer builds to get a idea on it and note some important points about the frame layout,structure and allignment So, that my printer build is properly stable and strong to withstand the demands.

- Studied best practices in frame layout and structure.

- Compared real-world printers for strength and stiffness.

- Started listing required mechanical components.

Time Spent: 4 Hours

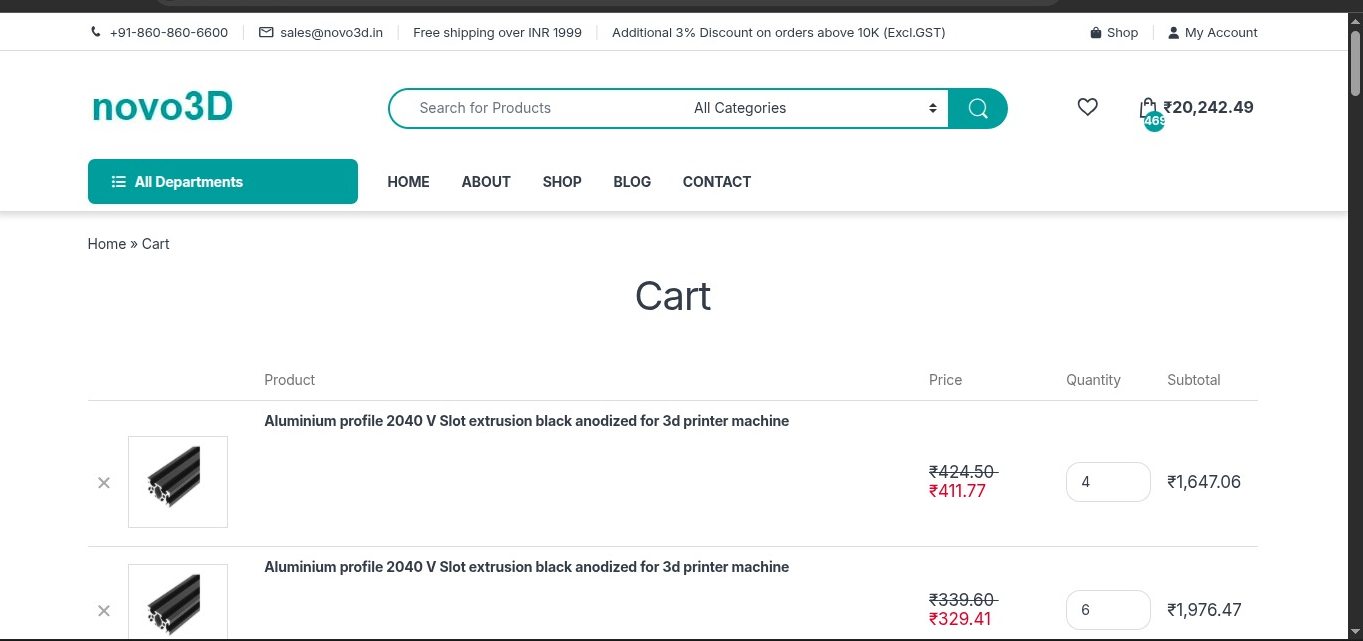

June 14th : Finalizing Basic Components

I researched about the 3d Printers parts and there types and use cases So , I can choose the perfect and best options for my build to get more performance and quality in printing.

- Finalized most mechanical parts after researching prices, compatibility, and reviews.

- Compared 3–4 websites for sourcing.

- Shortlisted components based on quality .

Parts Chosen:

- 2020, 2040, 4040 Aluminum Extrusions

- MGN12 Linear Rails

- V6 Hotend

- NEMA 17 Stepper Motors

- Octopus v1.1 Mainboard

- 8mm Lead Screws

Time Spent: 4 Hours

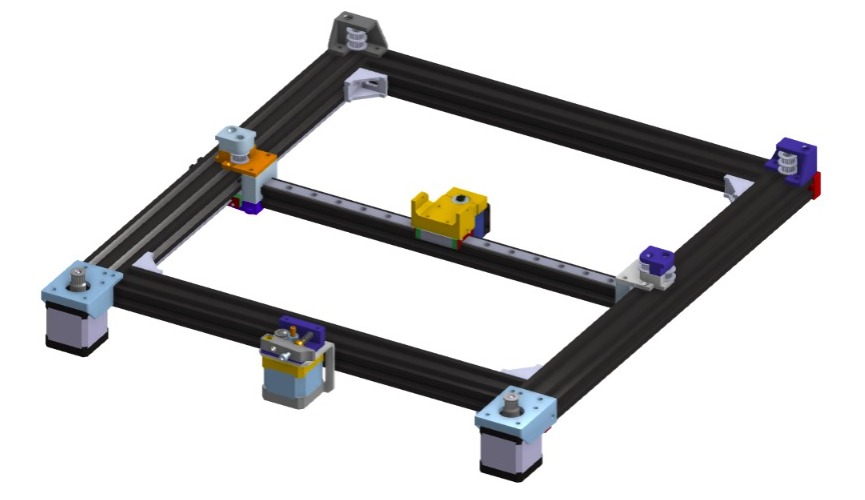

June 15th : Core-XY Gantry Research

For the Core-XY build i researched about various top Gantry design which are easy to build with less parts and rigidity.Finally i found the CoreXY Frame V2.0 the best option but it also has some flaws.

- Explored top gantry designs suitable for MGN12-based Core-XY setups.

- Found CoreXY Frame V2.0 design as a good match.

- Identified compatibility issues and noted required customizations.

Time Spent: 3 Hours

June 16th : Customization of Gantry & Parts

After knowing about the flaws in the 3d models from CoreXY Frame V2.0 I redesign them with keeping rigidity and compatibility with 2040 in mind.For this take proper measurements and make there proper models.

- Modified gantry design to support 2040 frame profiles.

- Designed a custom extruder holder.

- Enhanced structural parts for more robustness and strength.

Time Spent: 6 Hours

June 17th : Finishing Gantry Modifications

After making the top gantry parts I assembled them and check for any error in it and everything alligned perfectly.Then i make a proper assembly of the parts to see the final look.

- Finalized tweaks to the CoreXY layout and saved edited parts.

- Verified alignment and mounting logic.

Time Spent: 6 Hours

June 18th : CAD Part Collection

For full assembly I explored different websites and then dowload all the prebuilt CAD models for the parts to be used in the design and then make a proper folder for them.

- Searched for and imported CAD models of all standard components from GrabCAD & Thingiverse.

- Adjusted sizes and geometry where necessary.

Time Spent: 4 Hours

June 19th : Custom CAD Part Design

I look for all other custom parts that i need to make for assembly and after that i took the measurements and made 3d models for them. - Modeled custom brackets, joints, and mounts using Onshape. - Measured physical dimensions of real parts and matched CAD accordingly.

Time Spent: 5 Hours

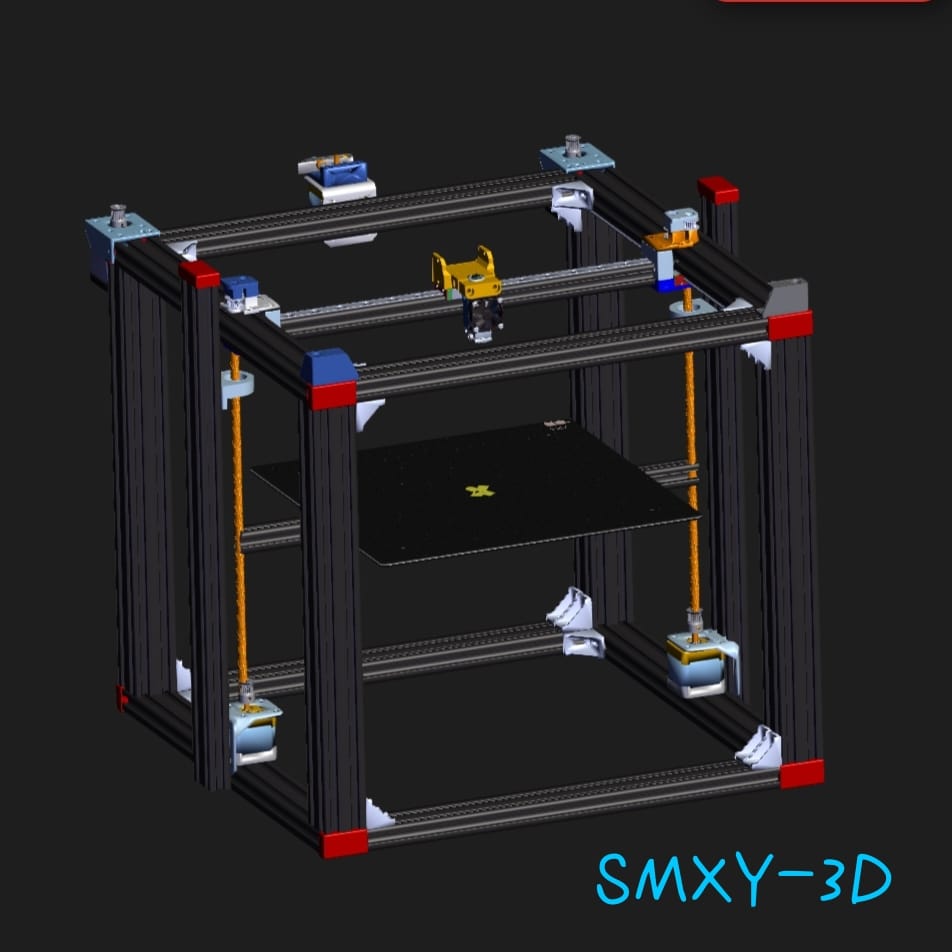

June 20th : Preparing Assembly Setup

I organised all sub-assemblies and make a full assembly from it and verify the part compatibility to prevent any issues in the future during the build and designing. - Structured sub-assemblies (gantry, base, frame, etc.) to simplify final assembly. - Verified part compatibility across imported and custom parts.

Time Spent: 4 Hours

June 21st : Final Assembly in Onshape

- Assembled all parts in Onshape with proper alignment and looks.

- Focused on accurate bolt and nut placements.

- Took images and screenshots for documentation.

Time Spent: 7 Hours

June 22nd : Web Upload and Repository Setup

- Created GitHub repository with structure:

/CAD/Images/BOM/README.md

- Uploaded CAD files to GrabCAD and Thangs for open source access.

Time Spent: 3 Hours

June 23rd : BOM & Final Documentation

- Created a clean, organized Bill of Materials (CSV and Markdown).

- Documented each section in the README with:

- Features

- Instructions

- Images and Renders

- Wrote a mini journal and wrapped up documentation.

Time Spent: 3 Hours