Quartz58

JOURNAL.md

title: quartz58

author: tim

description: attempt at a next to no compromises keyboard

created_at: 2025-07-15

Total Time Spent: 97.75 hours

~May-July 14: Research

- Researched split keyboards, specifically Lily58 and Corne layouts.

- What I wanted in a keyboard/use, if I wanted a track pad, rotatory knob, leds etc.

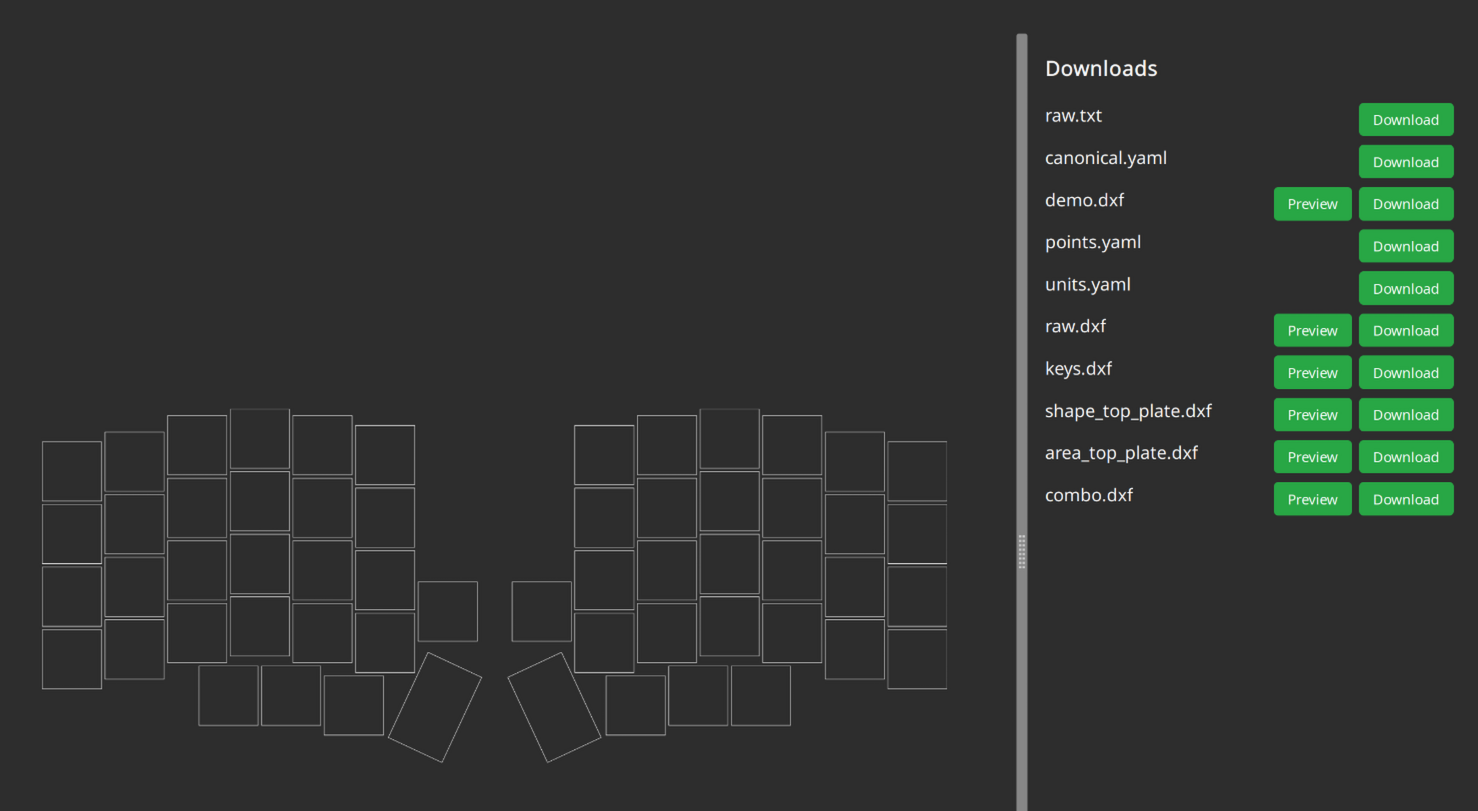

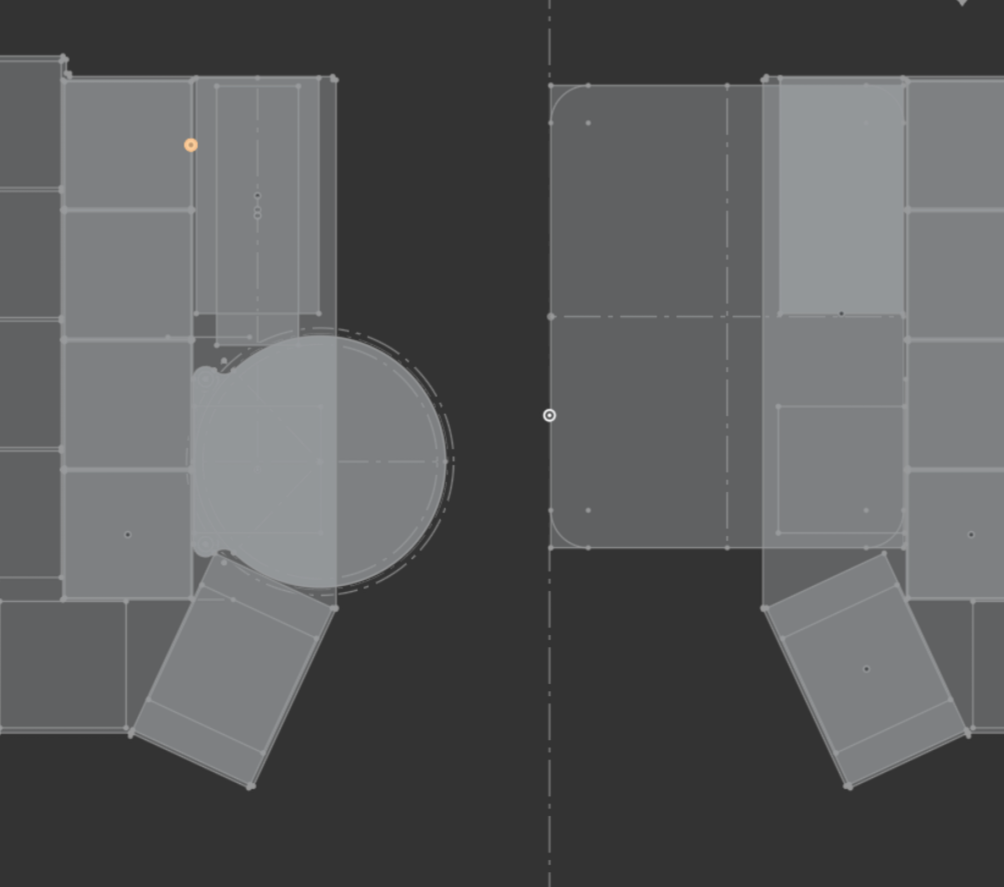

- At the same time learned about, how to use and created a layout on Ergogen, and starting on the pcb. (although later this was just used for key layout due to the amount of custom parts being used)

- Came up with a list and created a google doc to document everything found and what needs to be worked on.

- Compared and contrasted if I wanted a oled or nice!view epaper screen, with RGB to figure out battery life (just decided to go with nice!view and per key RGB and potentially 4000-2000mAh battery to also add weight)

- Also decided to go with MX switch footprint instead of choc, due to mx's superior sound and I'm not ready to commit fully to choc switches

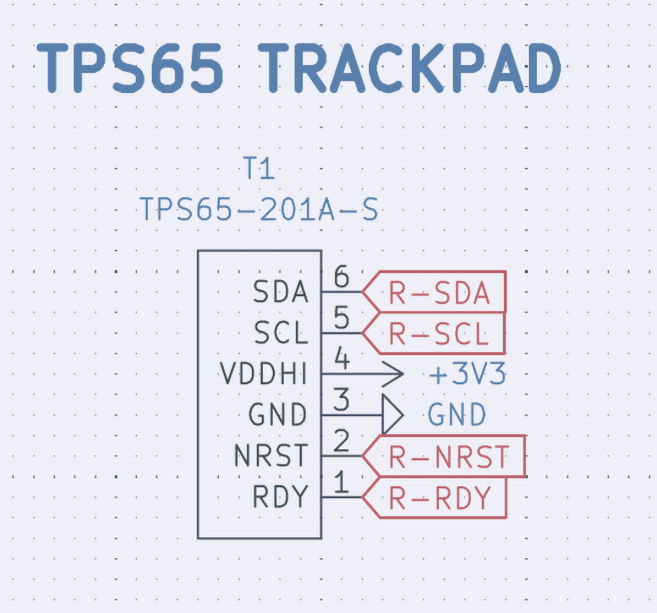

- Found more specific parts such as the TPS65 Touchpad, ANO rotary wheel and comparing that to models such as the cirque track pad, and conventional knobs

- Created onshape to continue to mess with the layout and the dimensions of the new parts

NOTE: I started doing early planning, and researching part on and off throughout march, early july due to other commitments, but majority of design and firmware development is happening in July (from now on).

Time Spent: 8 hours

July 15: True Beginning

- Created Github repo

- Uploaded all my documents here and started writing the journal

Time Spent: 1.5 hours

July 17: Progress & Decisions

Ergogen Config

- Simplified the Ergogen configuration to focus solely on the key layout, removing PCB-specific elements.

TRRS Conundrum

- Considered adding a TRRS port as a fallback for situations without batteries or when using a Pro Micro instead of a Nice!Nano (or equivalents).

- Faced challenges with limited pin availability and potential voltage conflicts if both sides are connected.

- Evaluated compatibility with ZMK firmware.

- Ultimately decided not to include the TRRS port for now. If issues arise, each half will be connected separately to the computer.

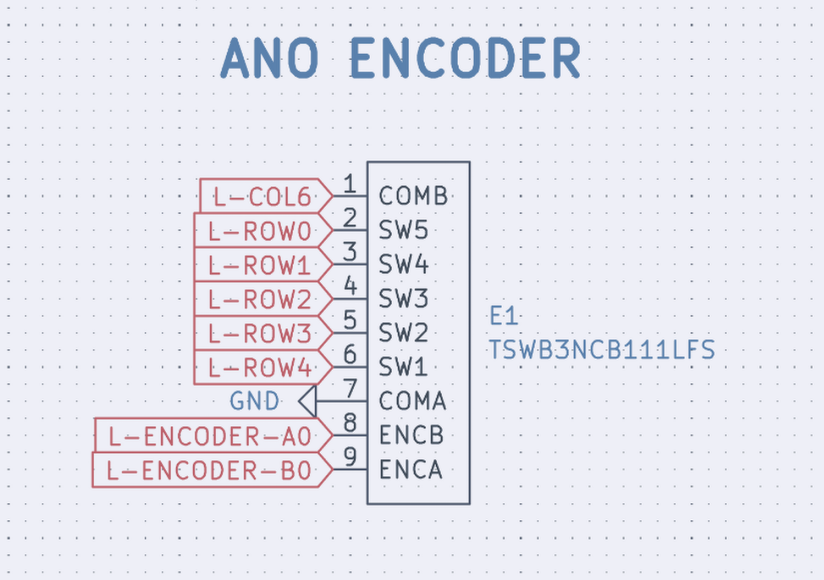

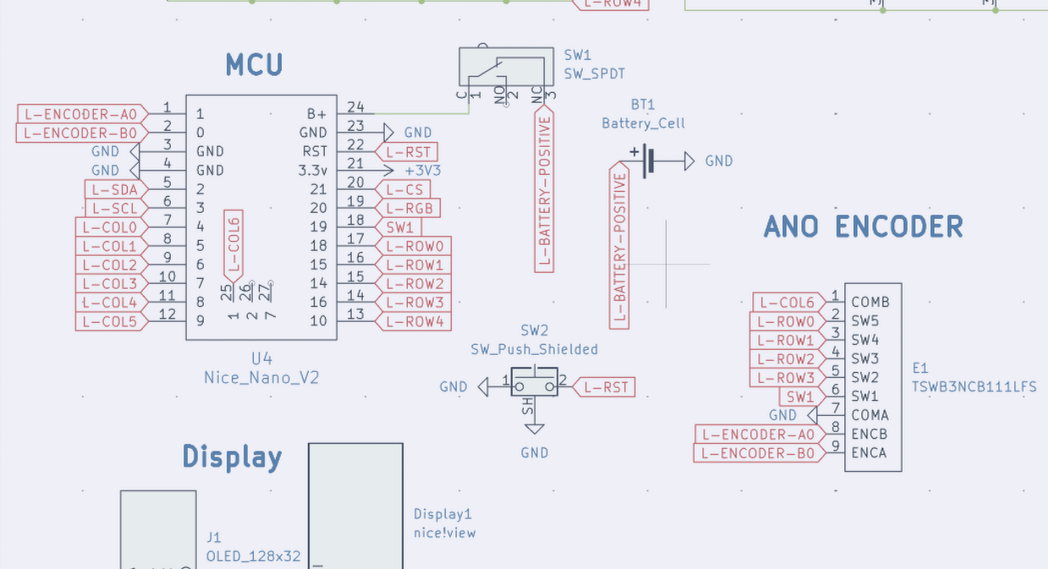

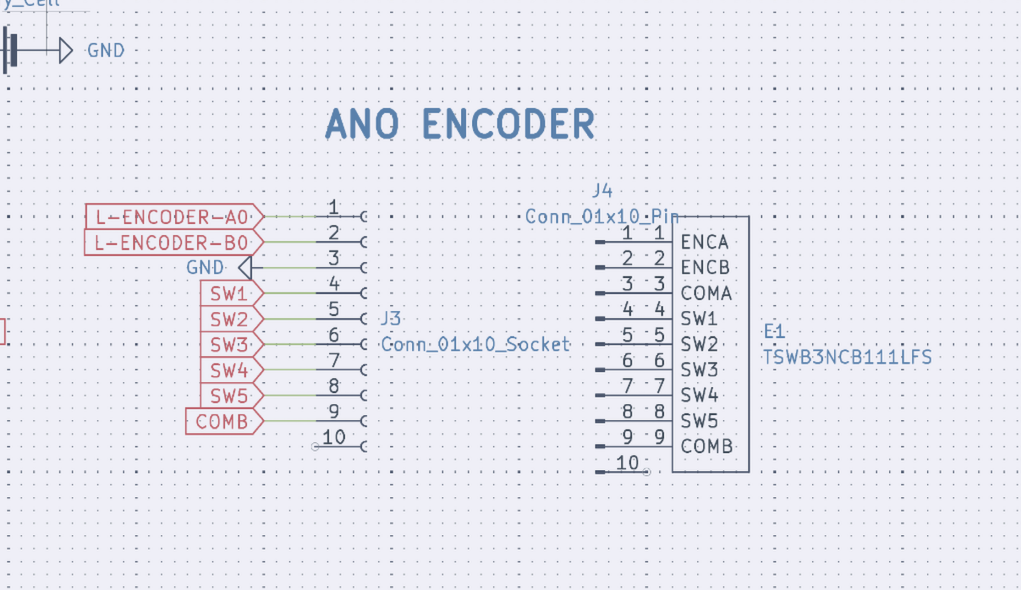

ANO Directional Navigation & Scroll Wheel Rotary Encoder

- Spent significant time searching for pre-made schematic symbols and footprints.

- Discovered the white version of the encoder (TSWB3NCB111LFS) available on Digi-Key.

- Located the data sheet, enabling future creation of a custom PCB footprint.

TPS65 Trackpad

- Found the data sheet, which will help in creating a custom symbol for schematic integration.

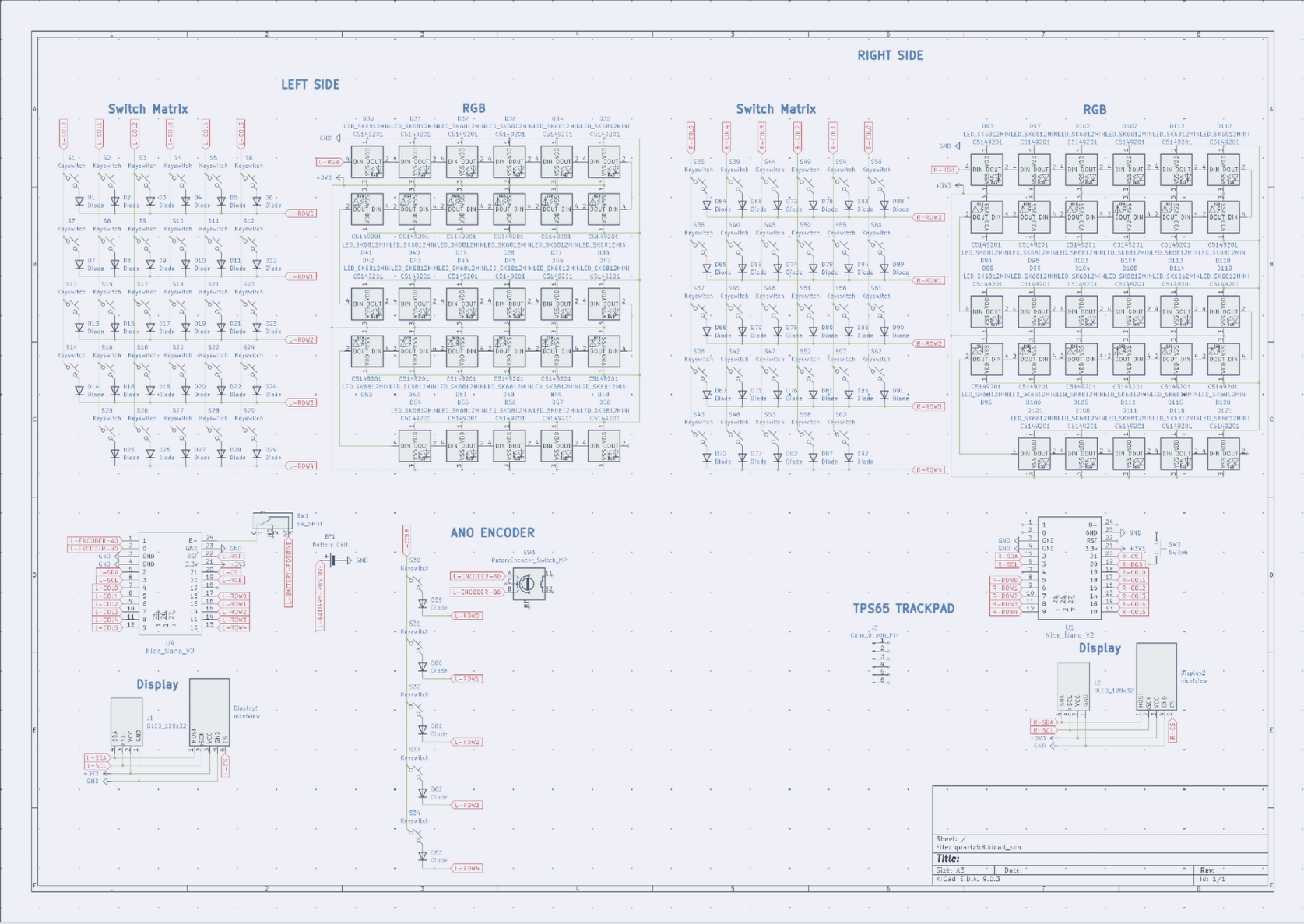

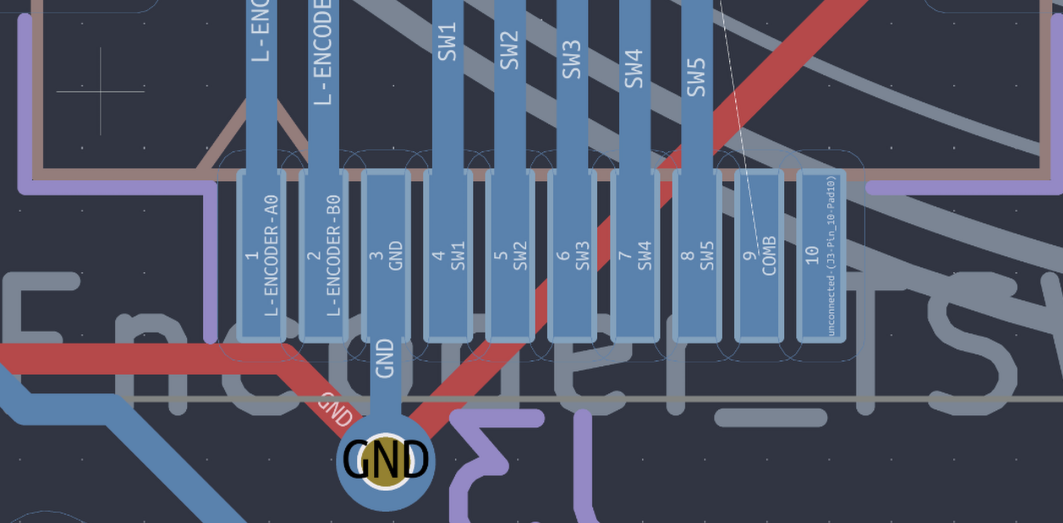

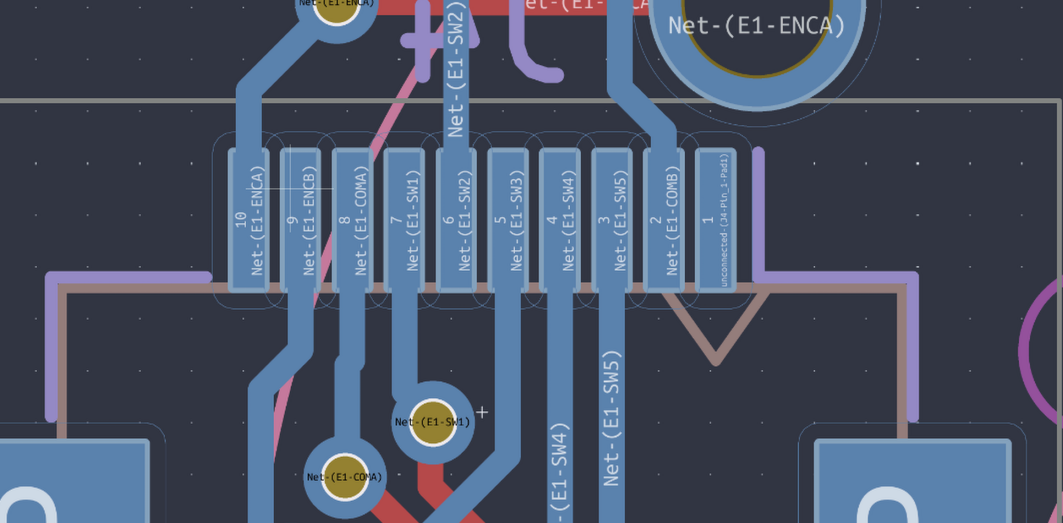

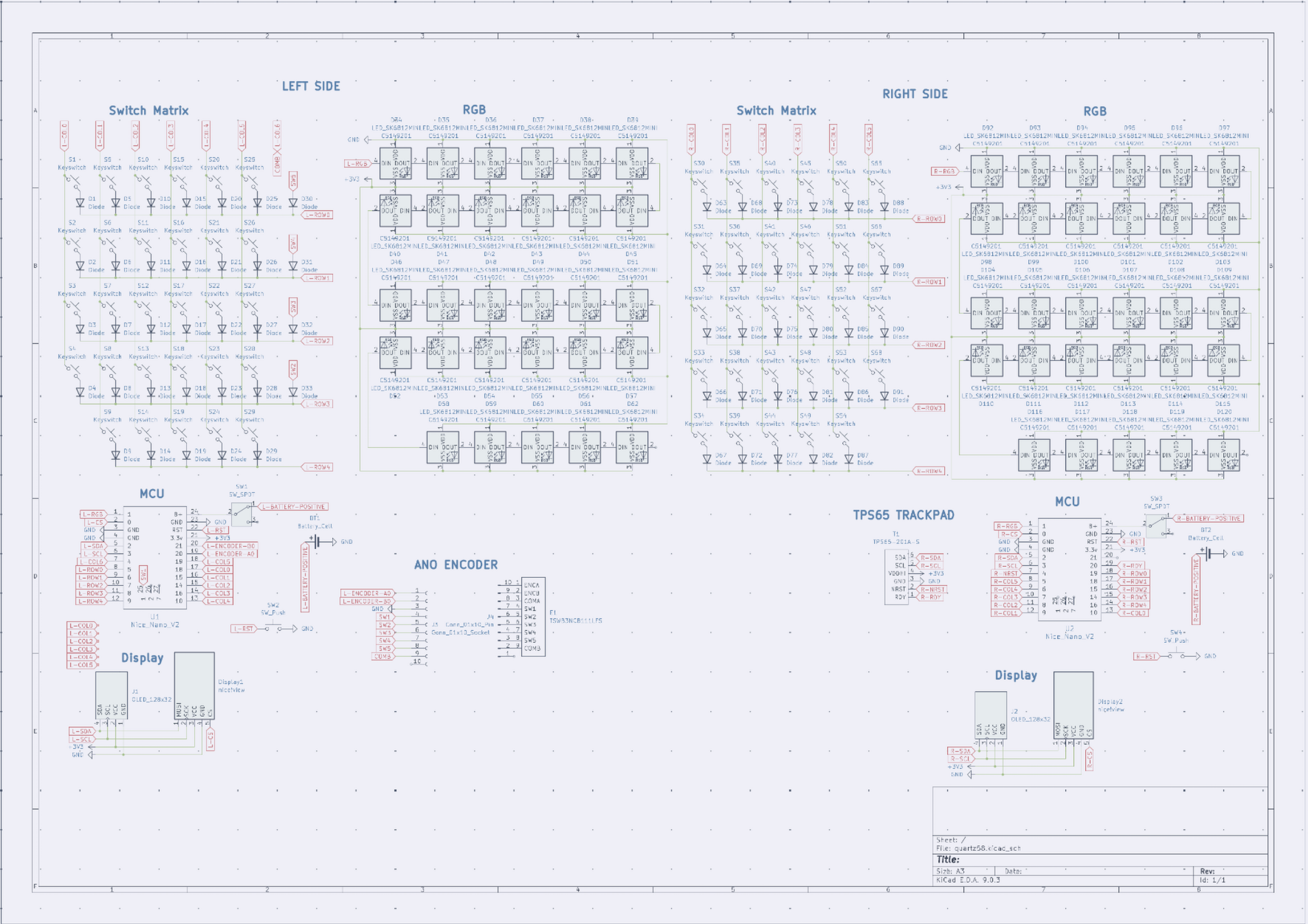

Schematic Progress

- Completed basic schematic elements.

- Next steps: create custom symbols for the ANO encoder and TPS65 trackpad.

Time Spent: 6 hours

July 18: DOWN THE RABBIT HOLE

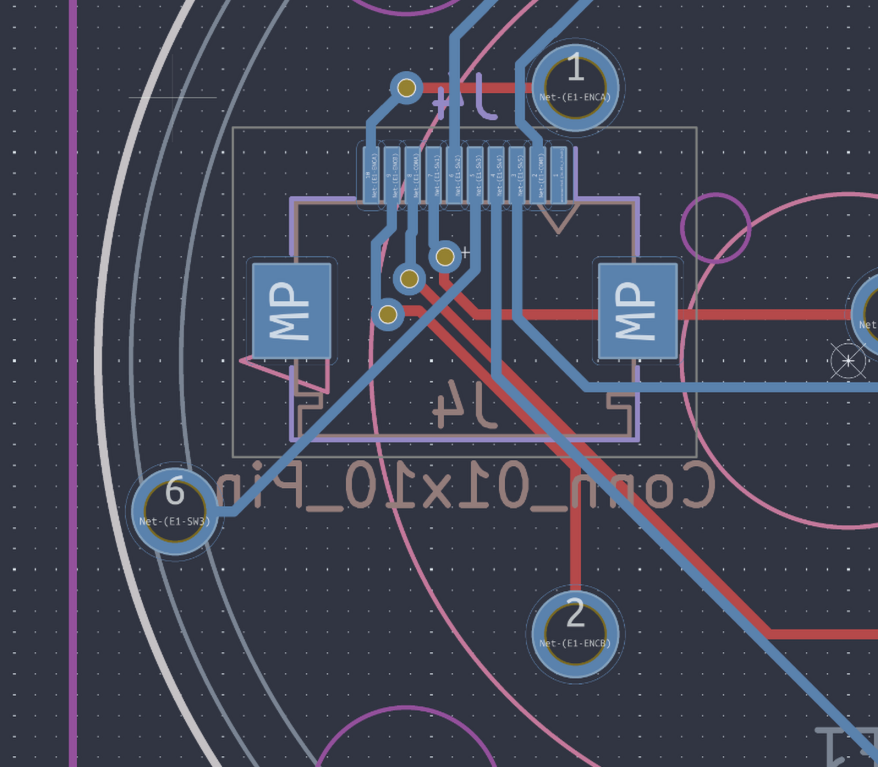

ANO Directional Navigation and Scroll Wheel Rotary Encoder

- After realizing that the TSWB3NCB111LFS encoder is not in stock anywhere, I decided to contact the creators of the soflePLUS2, which features this encoder.

- Reached out to them on Instagram; they mentioned being based in Malaysia, with their supplier in China—making shipping to Canada quite expensive.

- For now, I'll use the glossy Adafruit encoder, even though it may not match the color scheme.

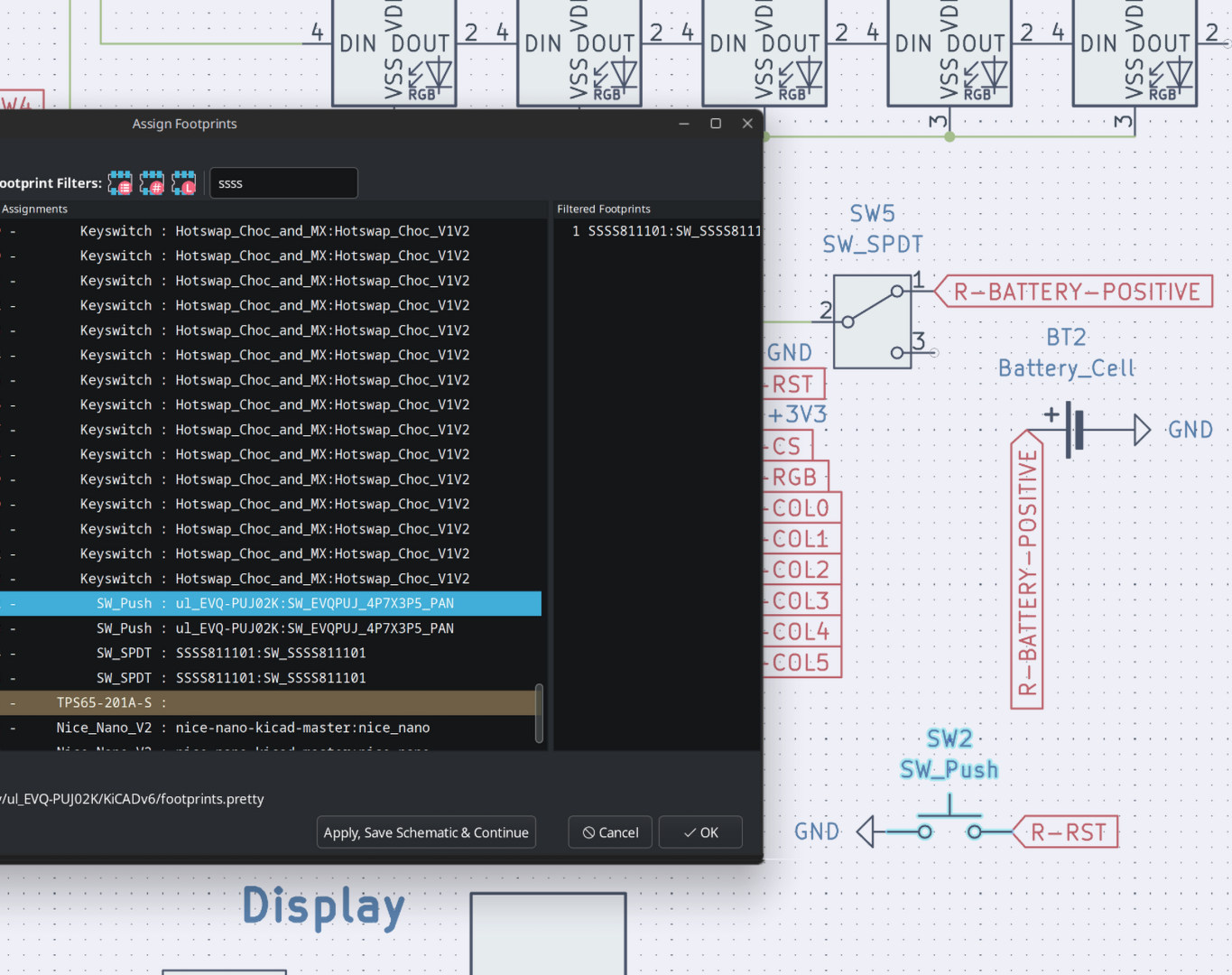

Schematic

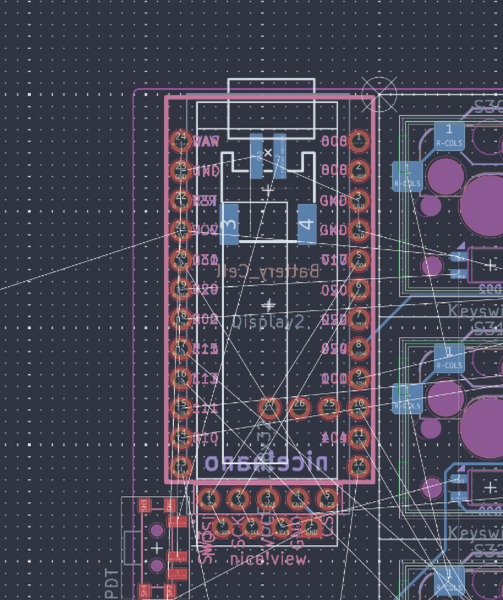

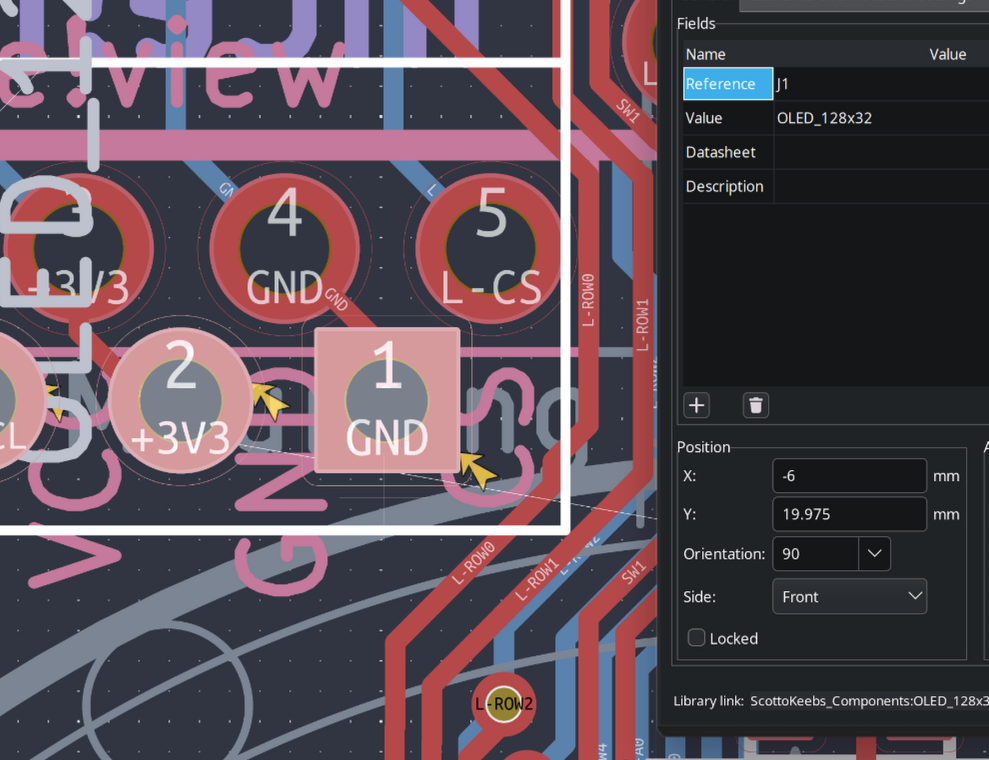

- Learned how to create symbols in KiCad and completed basic symbols for the trackpad and encoder.

- Refined more of the schematic and started assigning footprints.

|

|

|---|

Time Spent: 4.5 hours

July 19

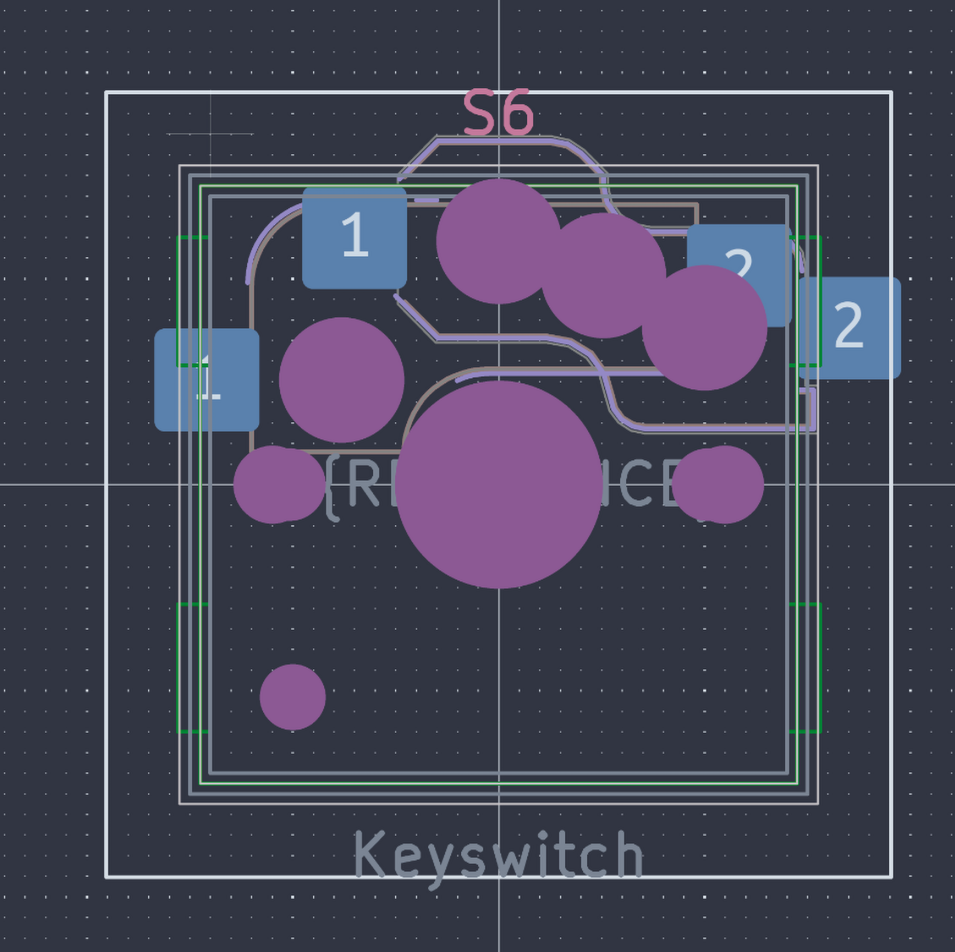

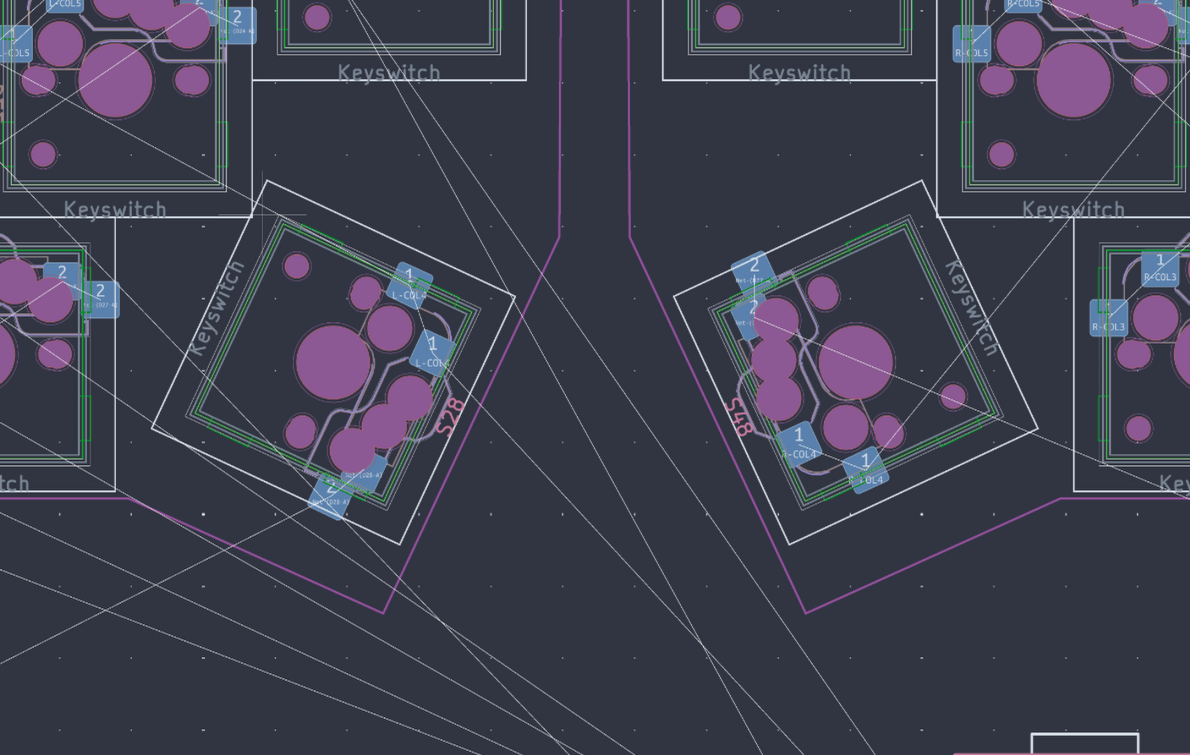

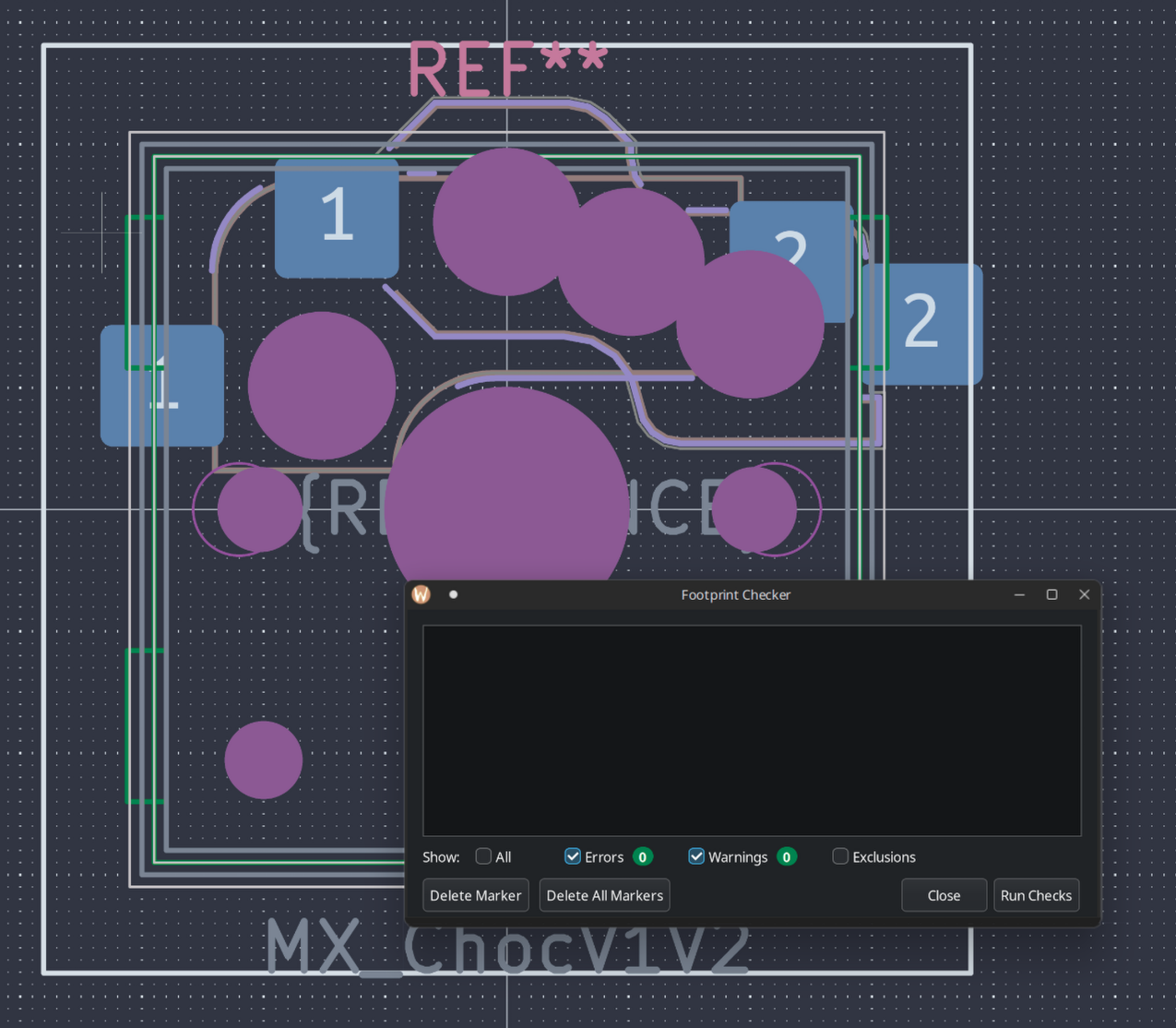

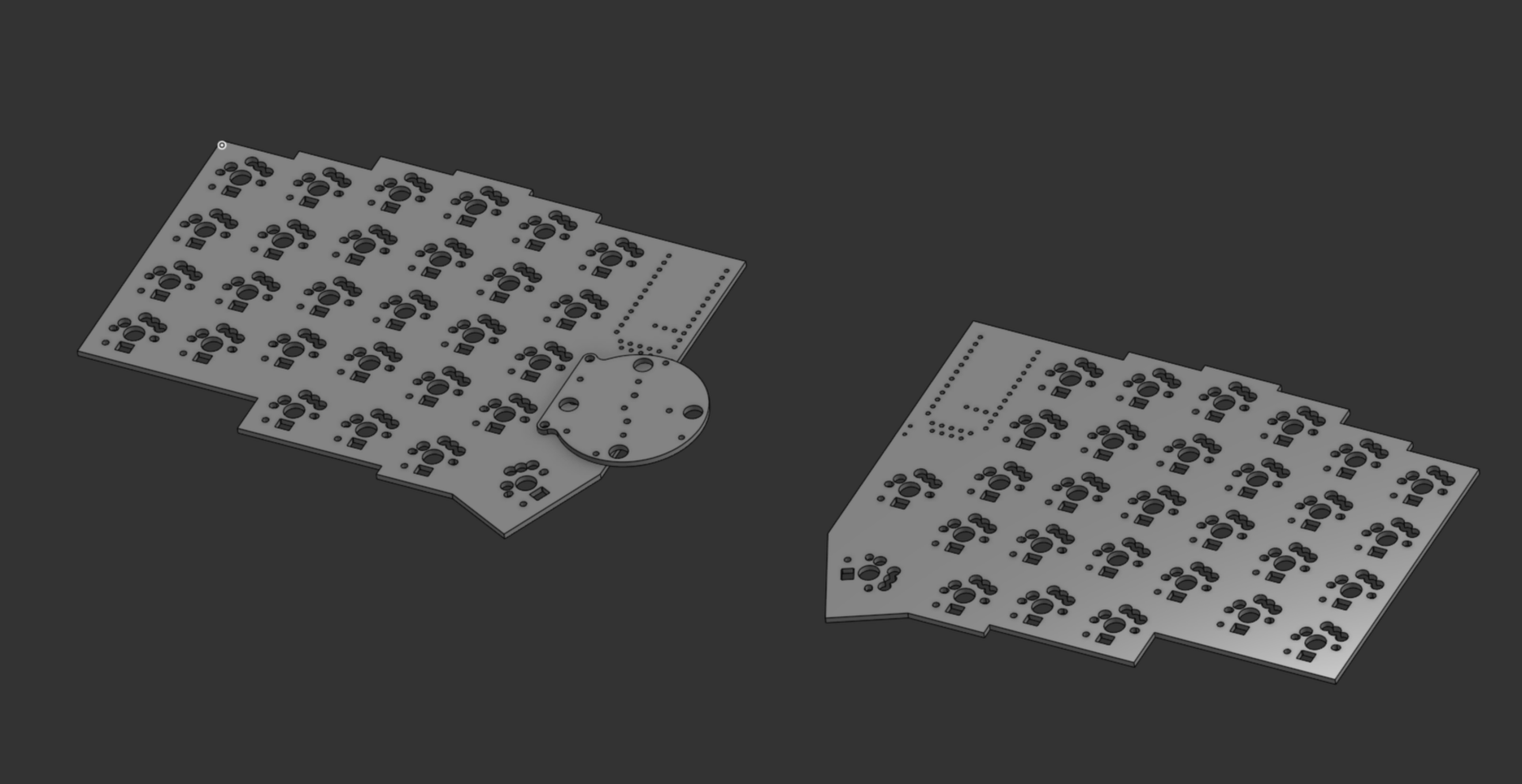

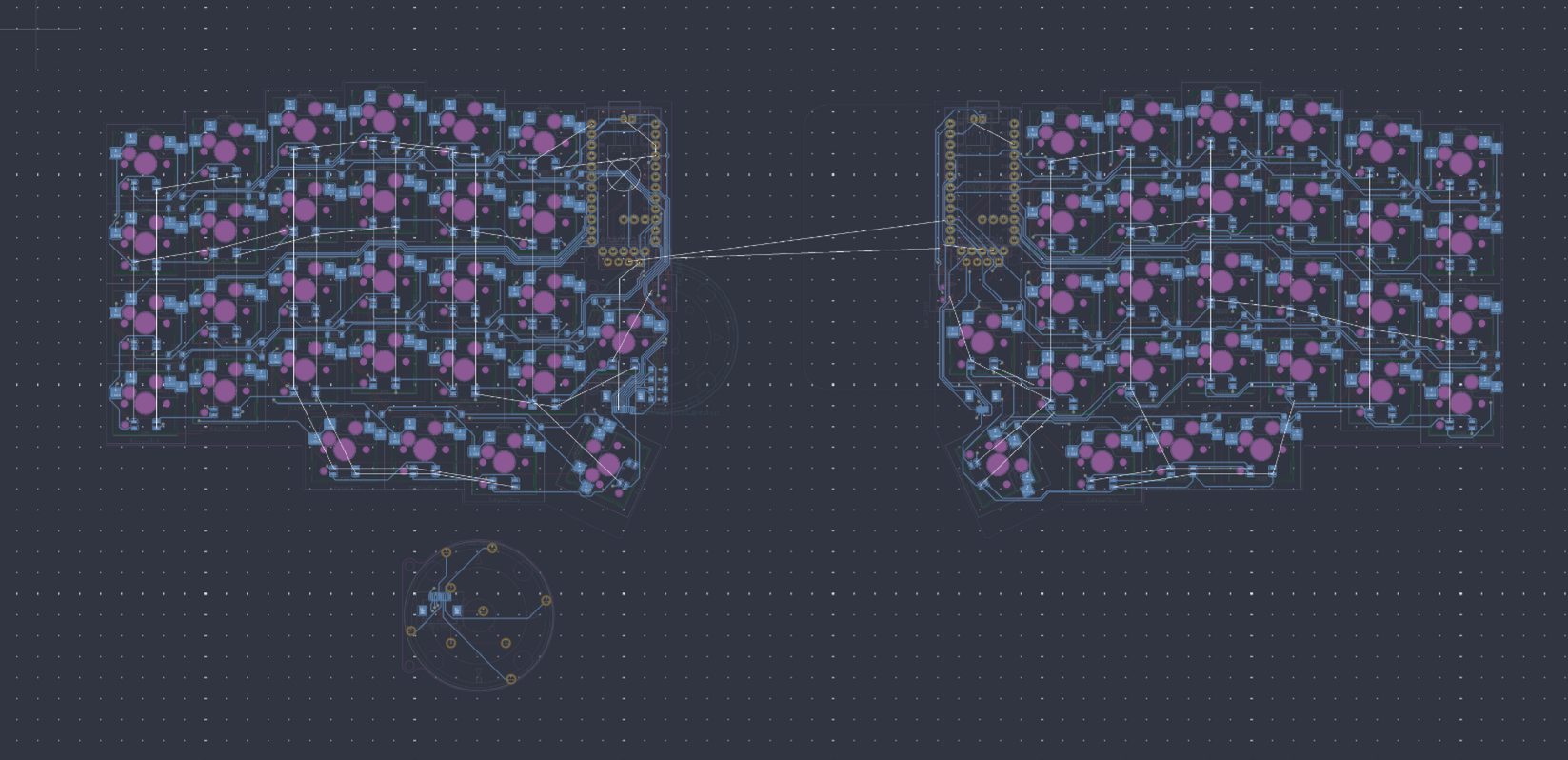

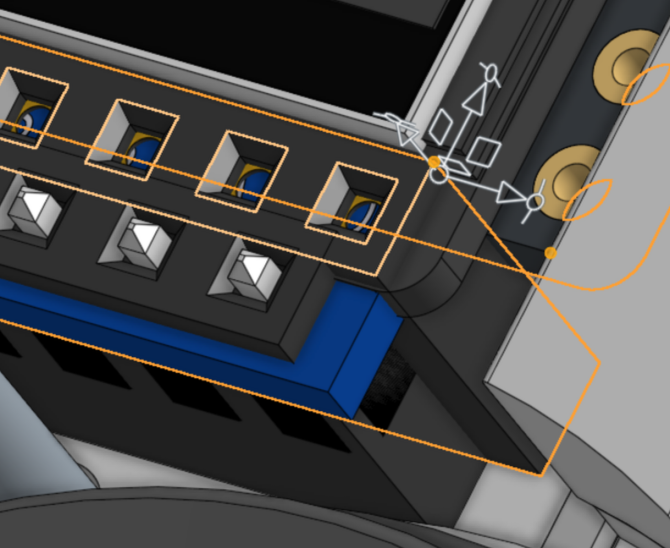

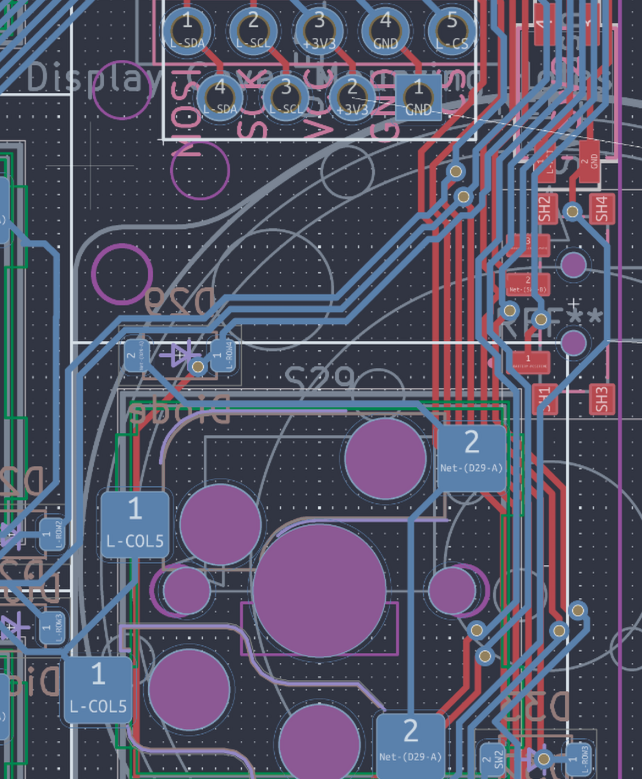

Custom Choc + MX hotswap

- Due to my indecision I decided to make sure that I could use both choc and MX switches on these pcbs.

- After tons of googling I couldn't find what I was looking for, although I could find it in one of the keyboards that I am using for inspo, the sofle plus 2.

- They just layered it on top of each other so you could just chose and they had the LED at the bottom still.

- So I decided to take the same approach and just layer two hotswap footprints on top of each other to achieve this, by following a guide on the kicad forms, which was just copying text from one file to another

- I then cleaned it up with some of the overlays stacking.

- I do plan on making it more polished with the outlines and looks more complete, but since it doesn't effect anything else right now, only asthenics I'll worry it about it later.

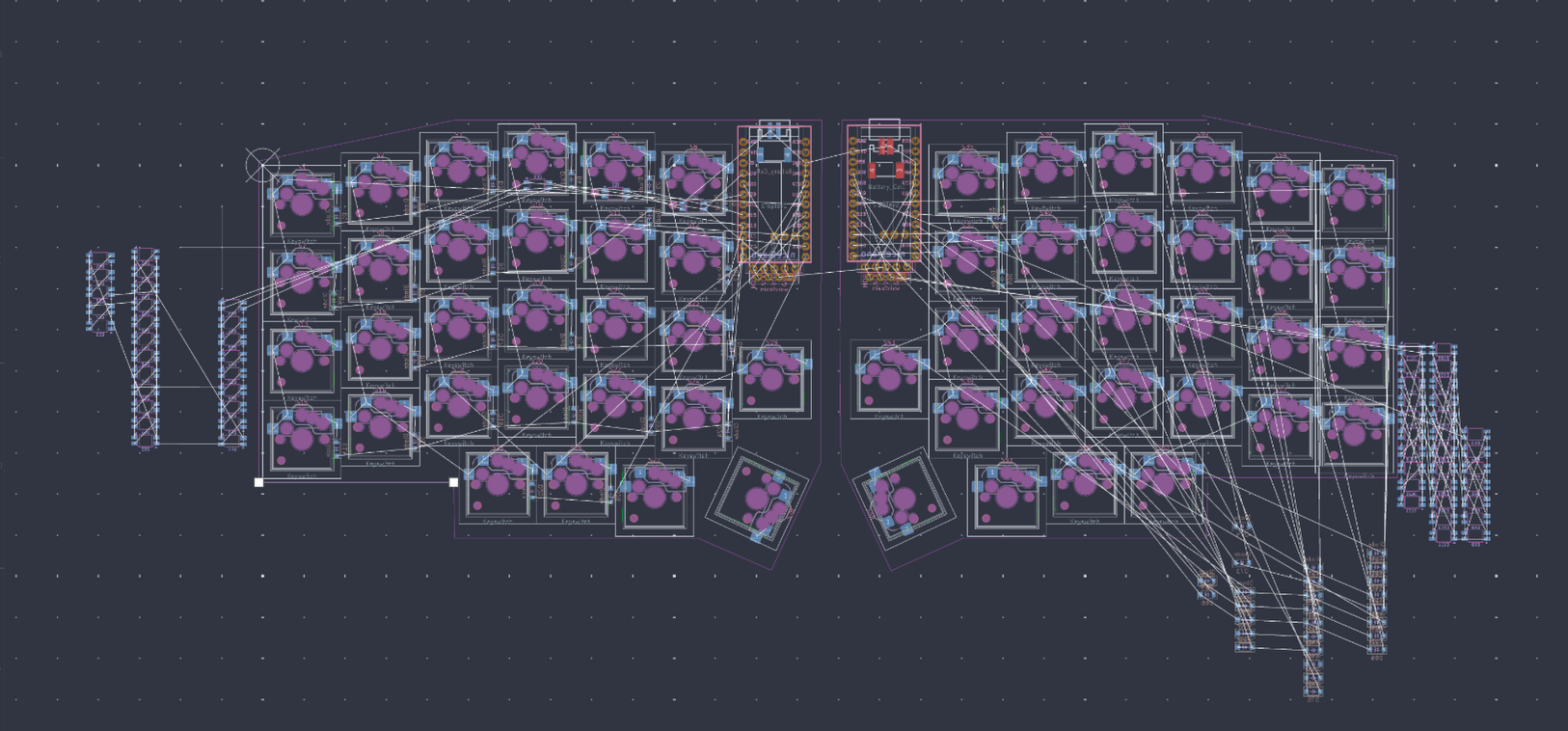

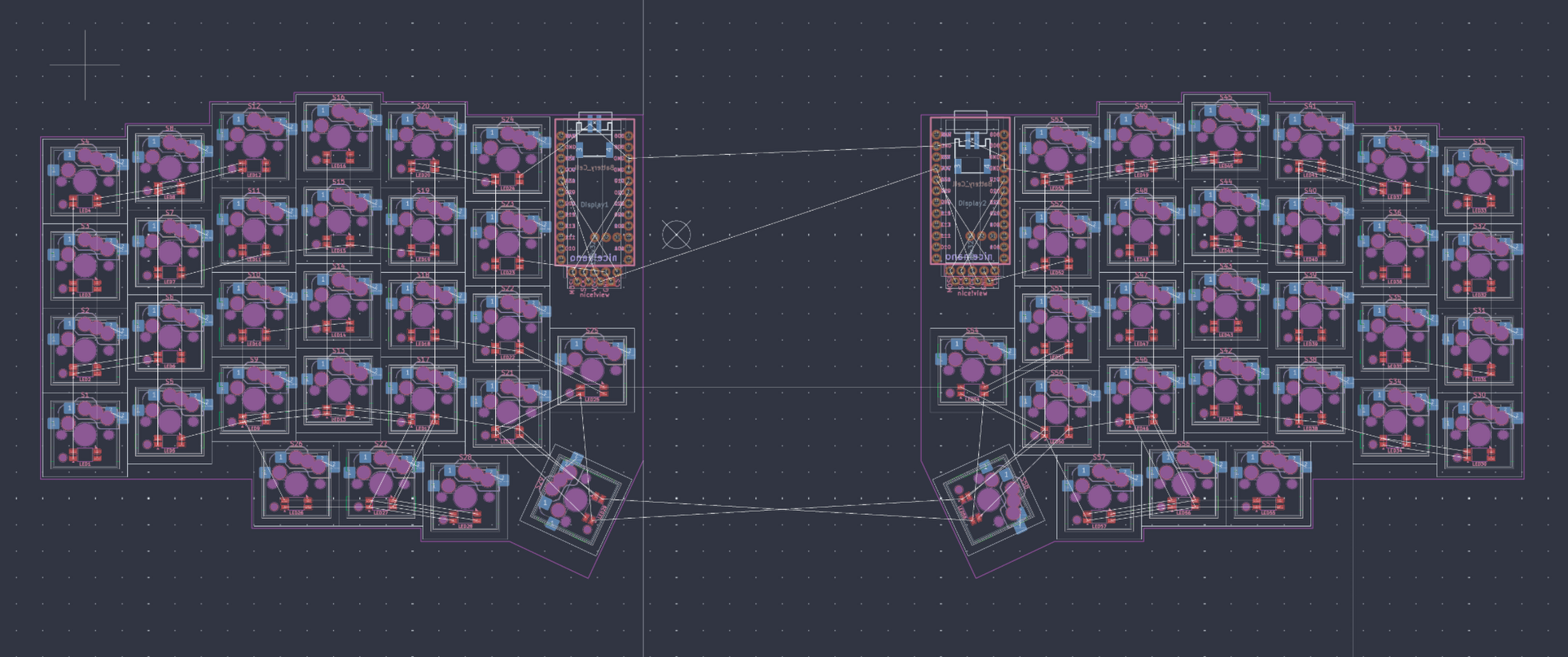

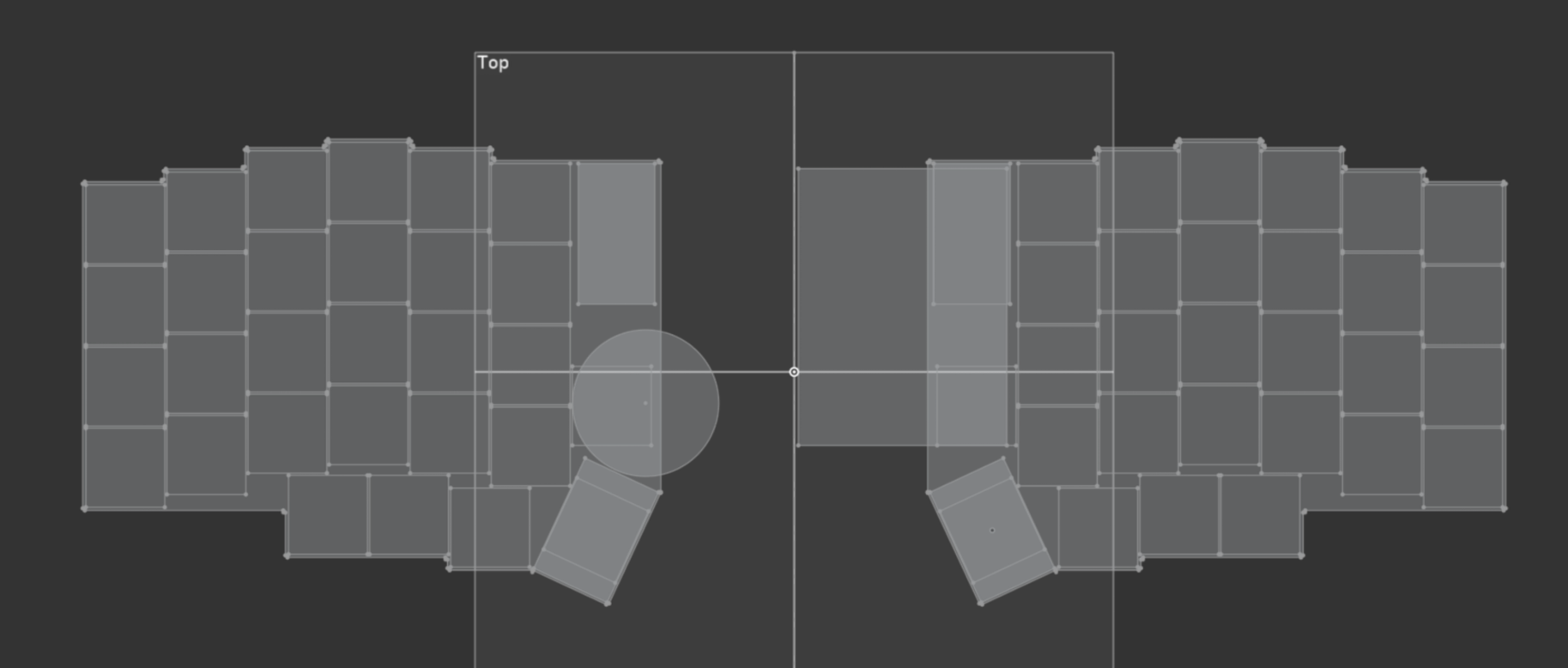

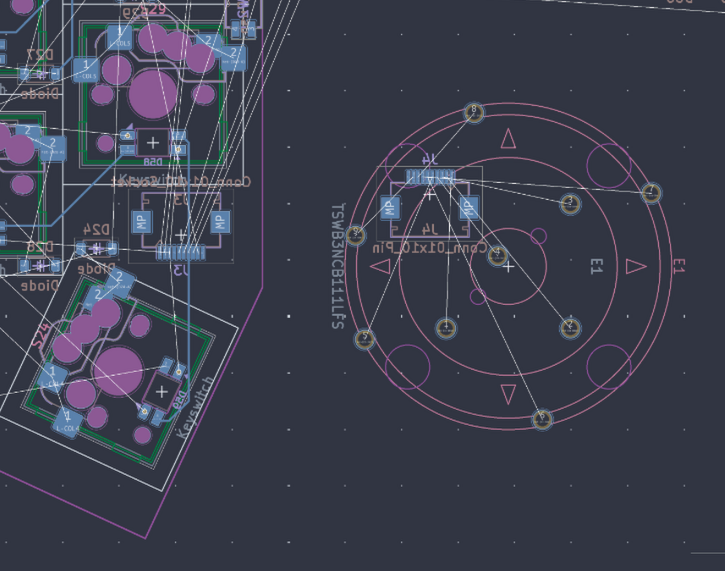

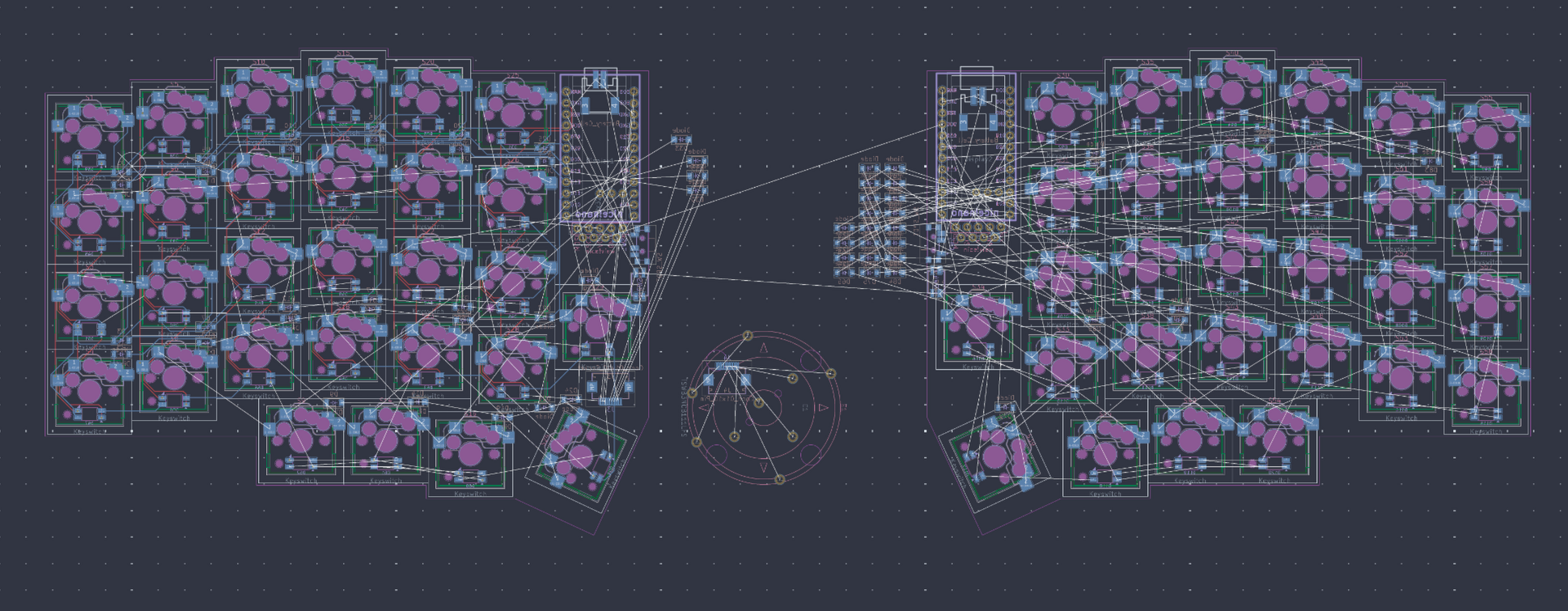

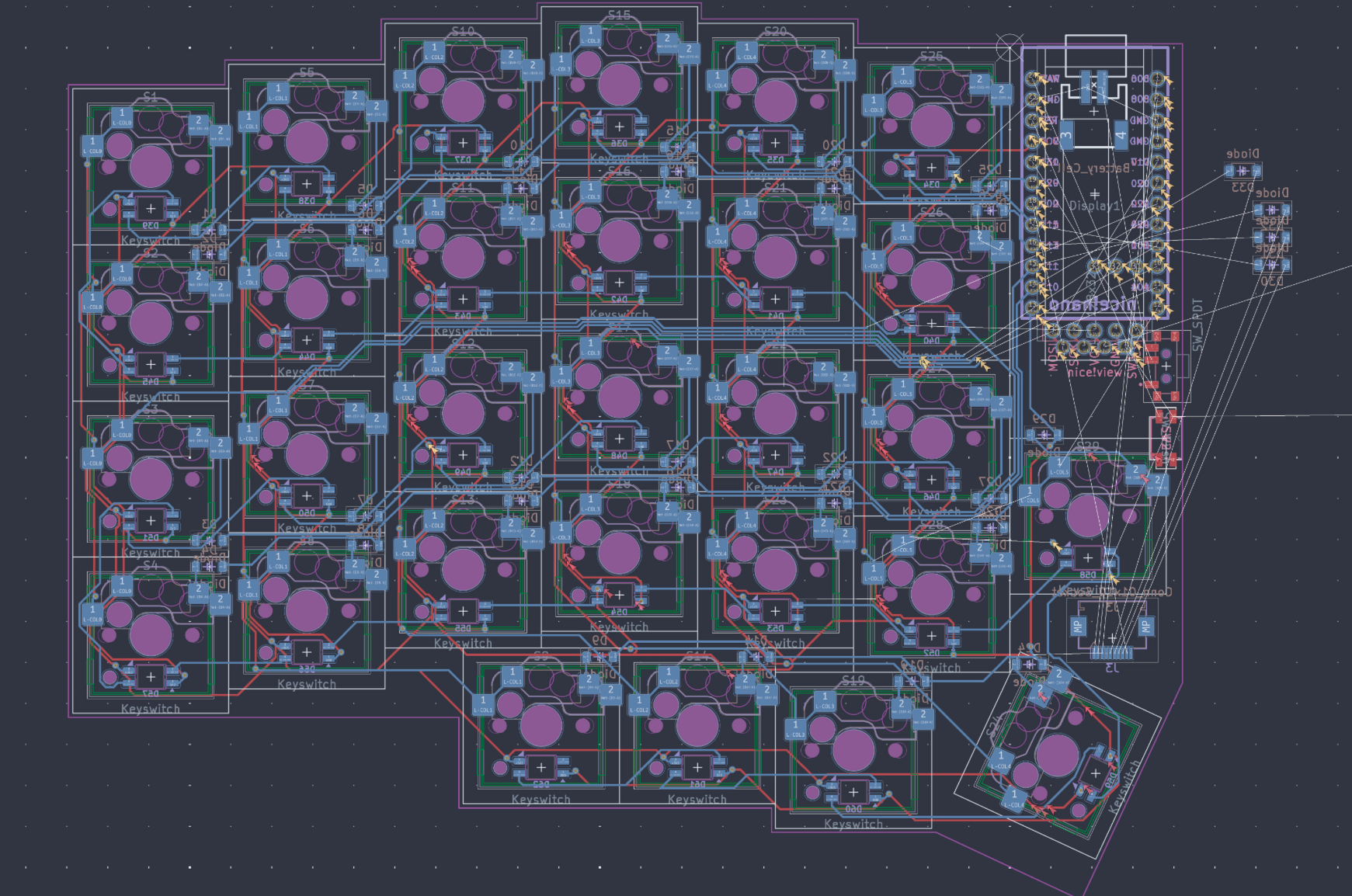

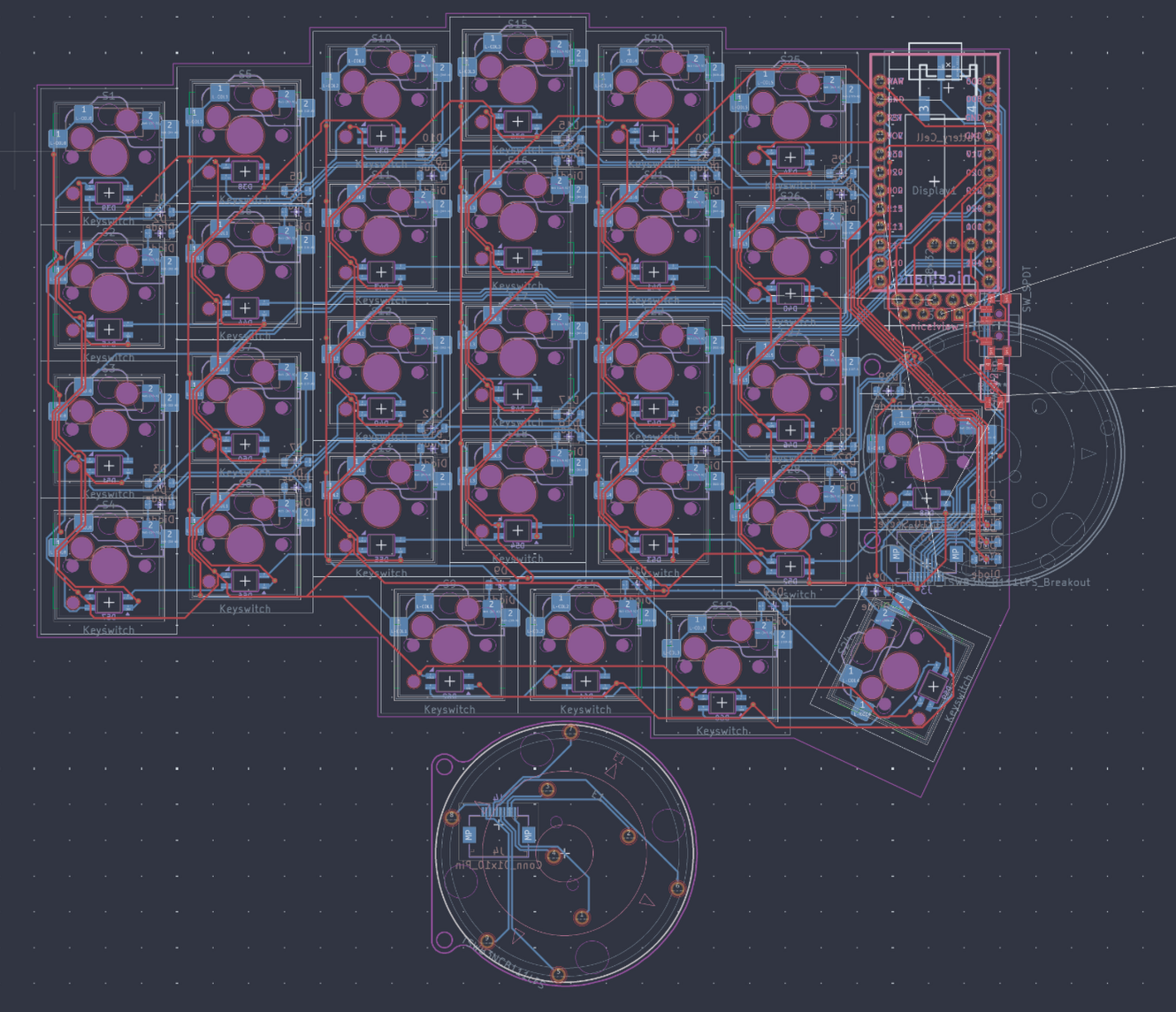

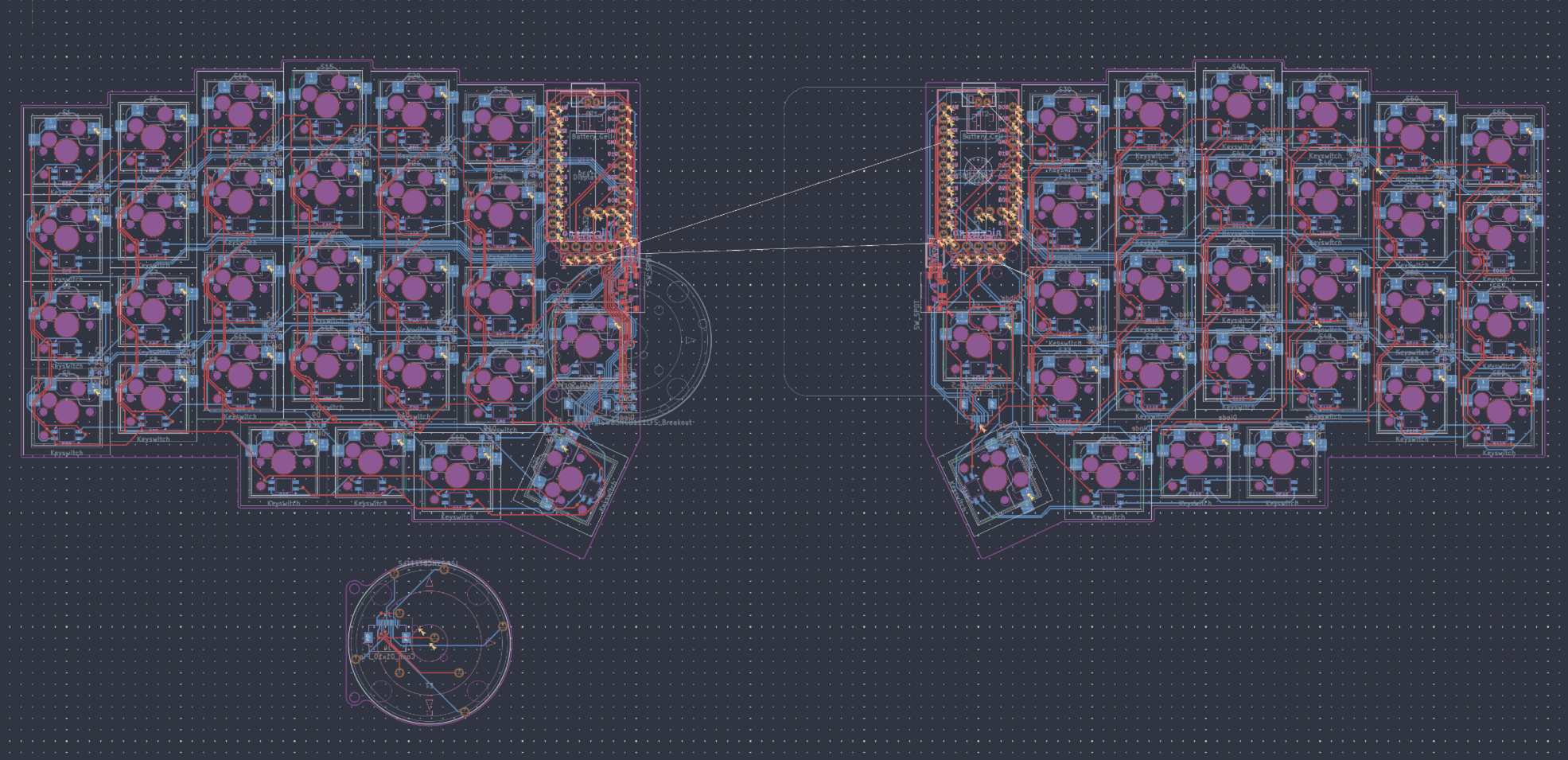

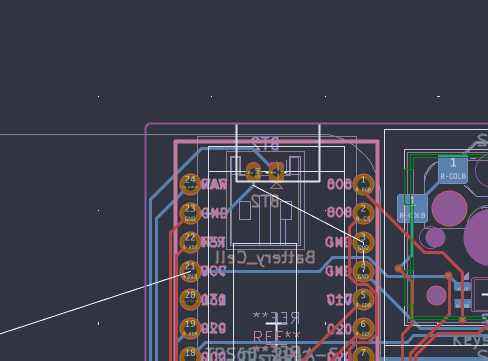

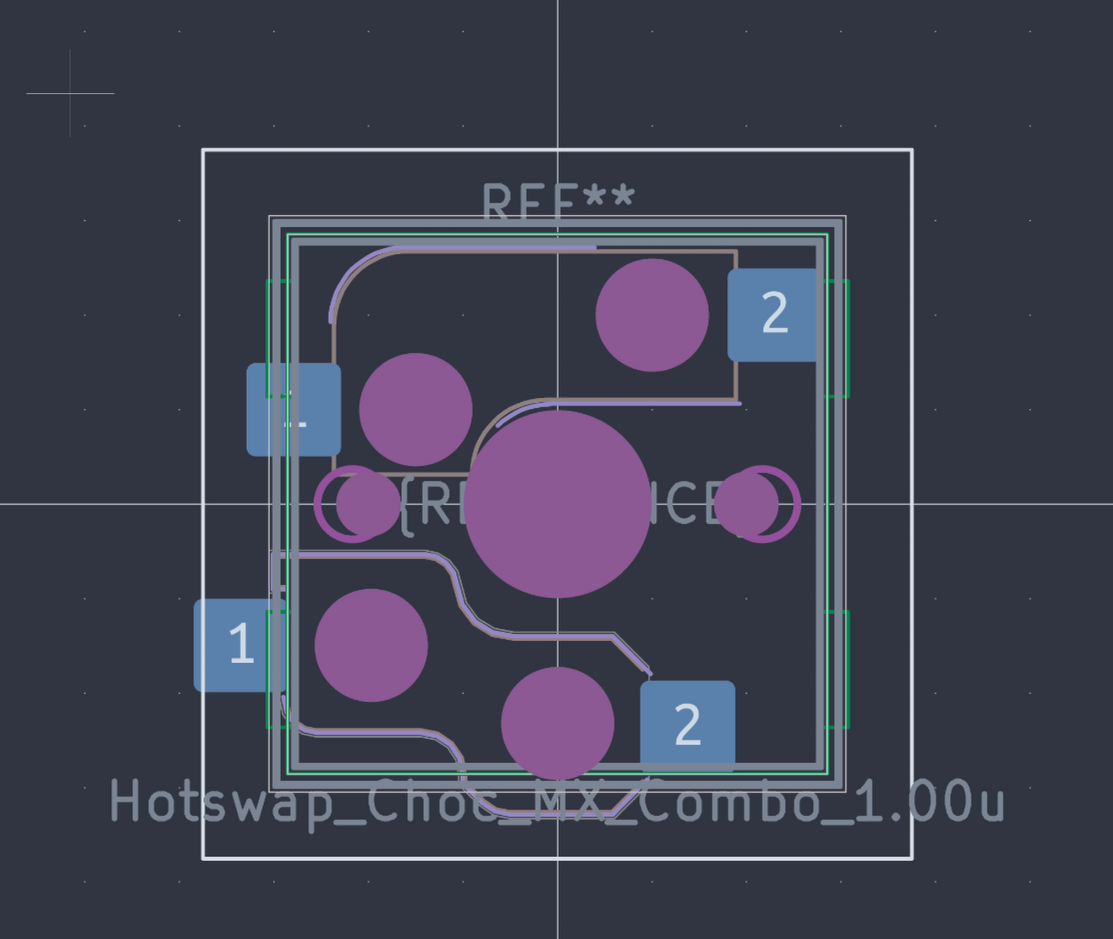

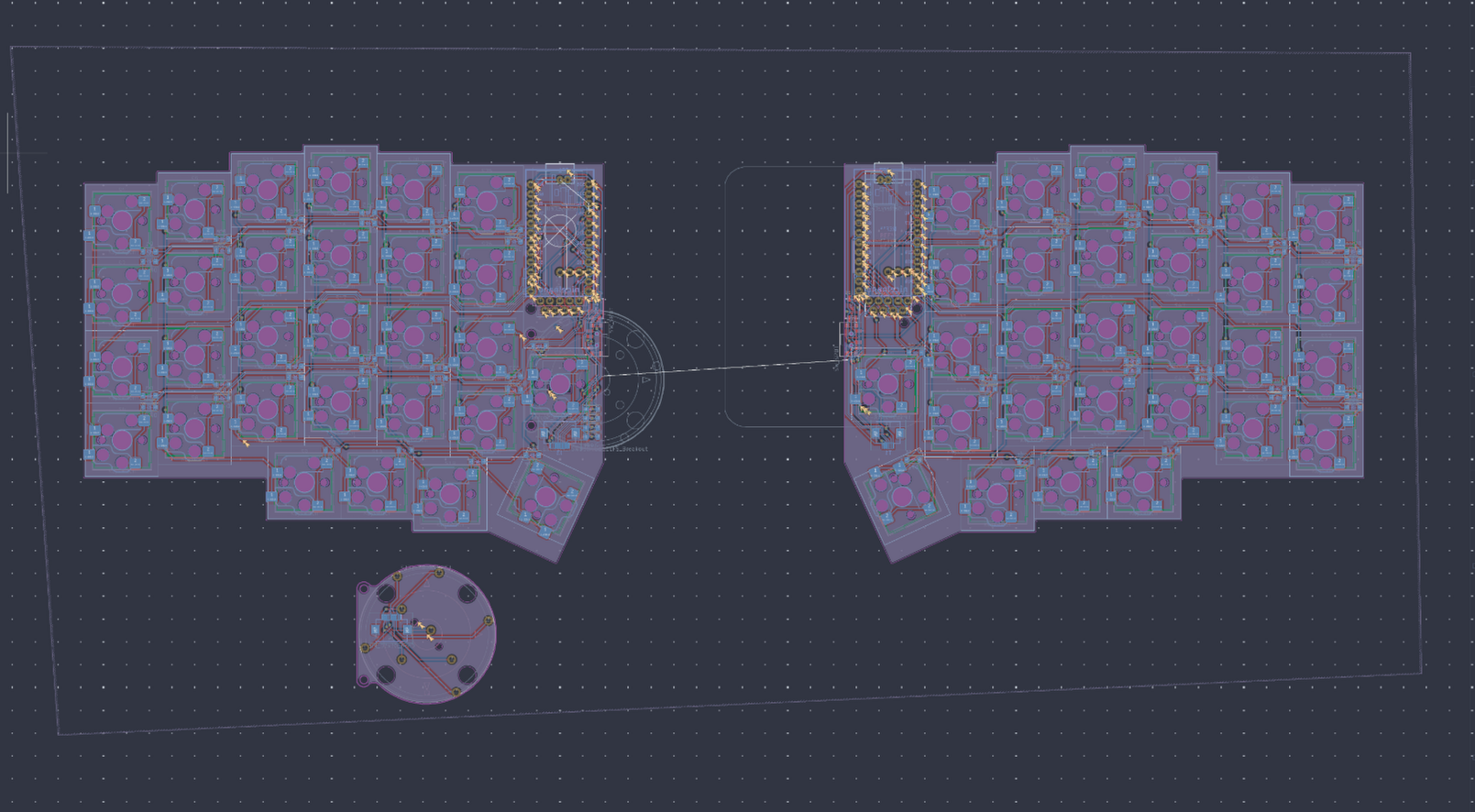

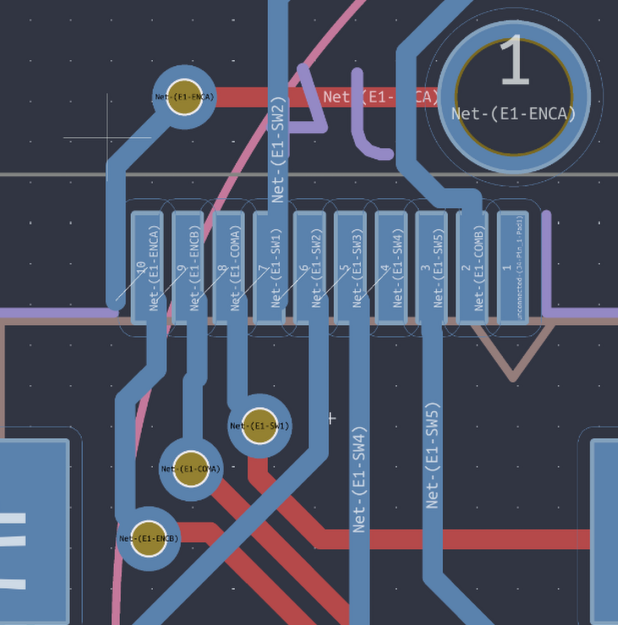

Starting PCB Laying out

- I first did all the basic stuff just assigning footprints, however I didn't for my trackpad and encoder as im making those later and I'll just insert it later.

- I then spent an hour just attempting to layout the switches according to the ergogen, then I figured out that I could just use the ergogen one, import it into mine, change the footprint to my type of switch

- I also roughly placed some of the components such as diodes and leds to get here

- Although when doing this I ran into a problem where my thumb key was a bit too close to each other so I had to go back to ergo gen and fix that, then import it back and align it by stacking a nearby switch to not ruin the other progress I've made

- So far my thoughts are that I might be way in over my head due to only ~10 days being left and still so much todo (CAD and zmk) and the goals I want to achieve with this keyboard, but I think I got this!!

Time Spent: 5.5 hours

July 23

- I had to take a break to focus on finishing my summer school, and today I just took the final exam and now I'm back, hopefully I can finish this in time

ANO Encoder Update

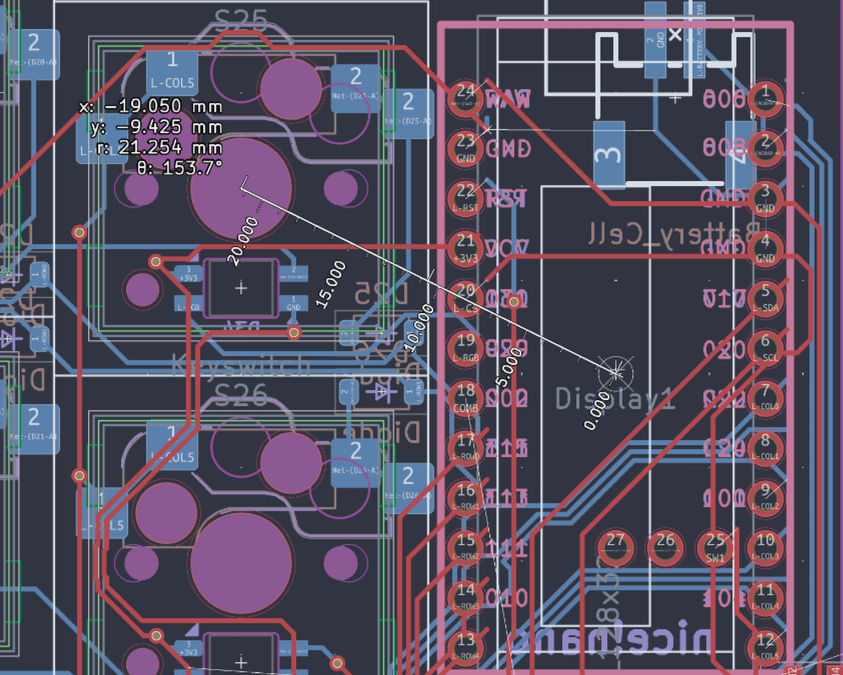

- After reviewing the encoders data sheet I realized I had wired the encoder wrong and I can't integrate SW1 into the matrix

- So I just used one of the middle pins on the nice nano

|

|

|---|

- Tomorrow I will make the pcb for this ANO Encoder

General Planning/PCB

- Figured that instead of just placing each led and diode one by one, which is repetitive and might lead to mistakes I will just instead just do it in ergo gen and change the footprints and assign them like what I did for the switches

- I might also do this for the MCU placement n stuff

- As I'm mixing 19.05mm with 1mm stuff which makes it tricky to make it all consistent

- which I started doing today, I also minimized the perimeter of the pcb to allow for

Time Spent: 1.5 hours

July 24

General PCB Stuff

- Readjusted my thumb key again to make it perfect with the references of onshape

- I decided I liked the look of a smaller pcb that minimizes the area instead of the normal lily58 so I changed that in ergogen (taking wayy longer than I thought bc ergogen isn't as easy to use as onshape)

- Also I put in the leds in ergogen so I can remove me manually placing it which could lead to mistakes, I didn't do this with the diodes like I planned but I want to place them fancy later to efficiently use up the space

- This lead me to basically restarting the pcb

|

|

|---|

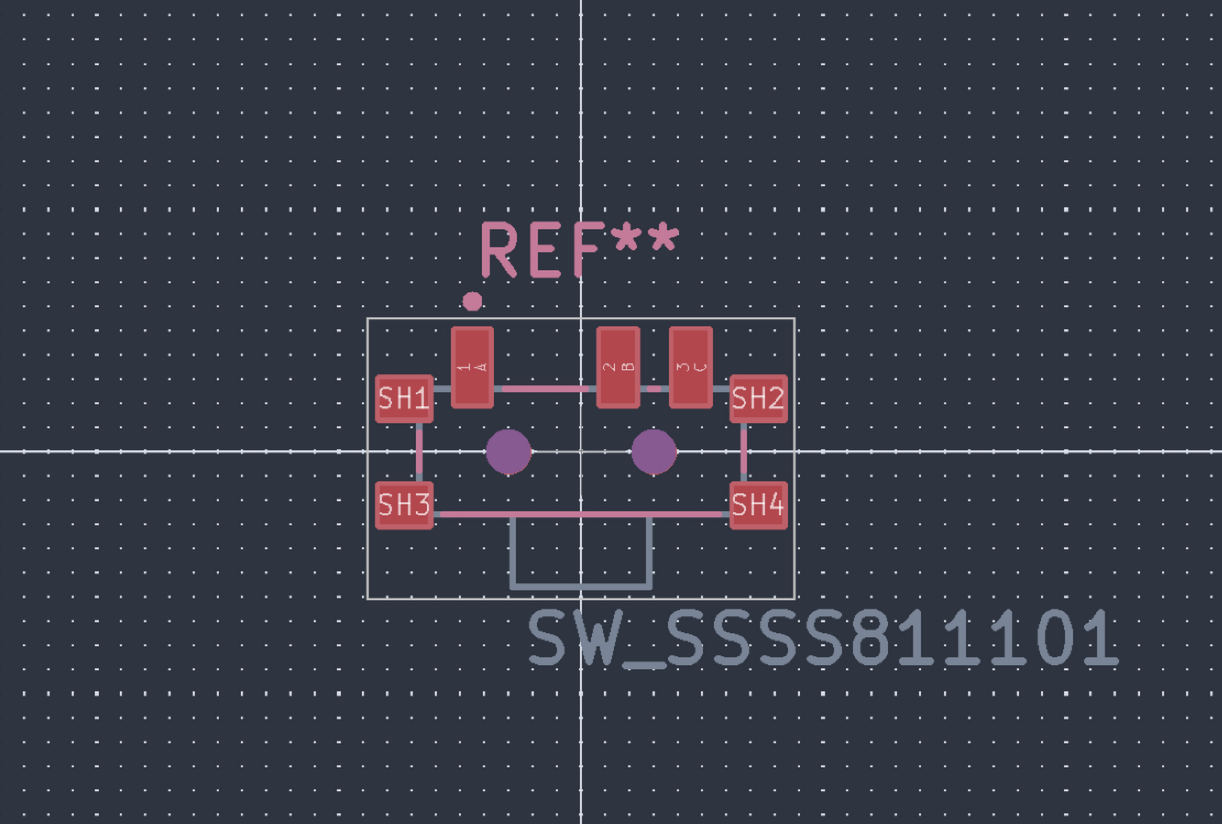

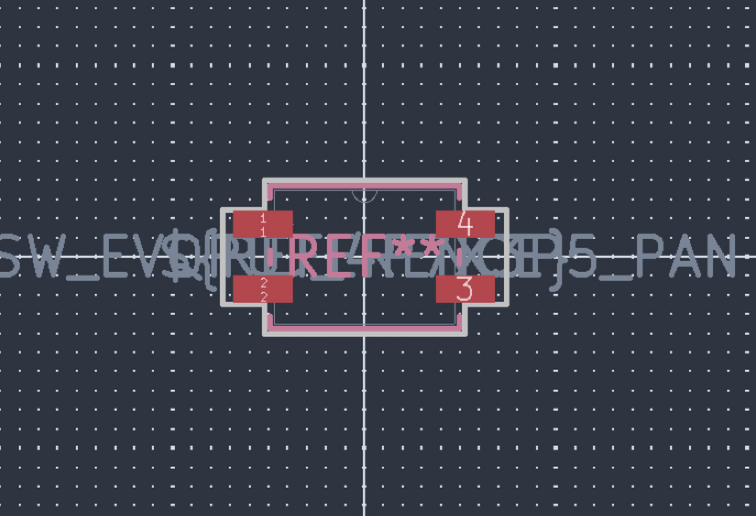

- I also found side mounting of the buttons and switches that I will be using!

- The SSSS and panasonic one, used on the typeractive keyboards

|

|

|

|---|

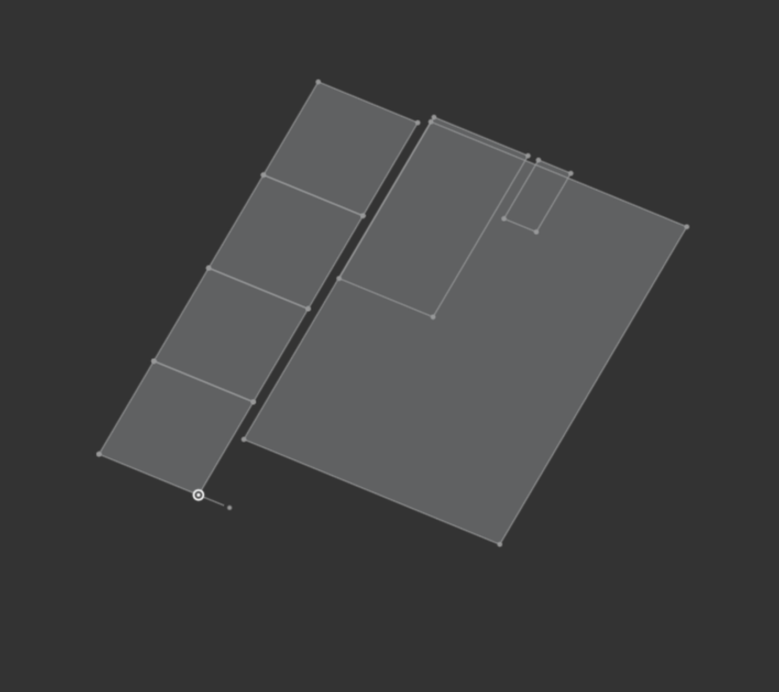

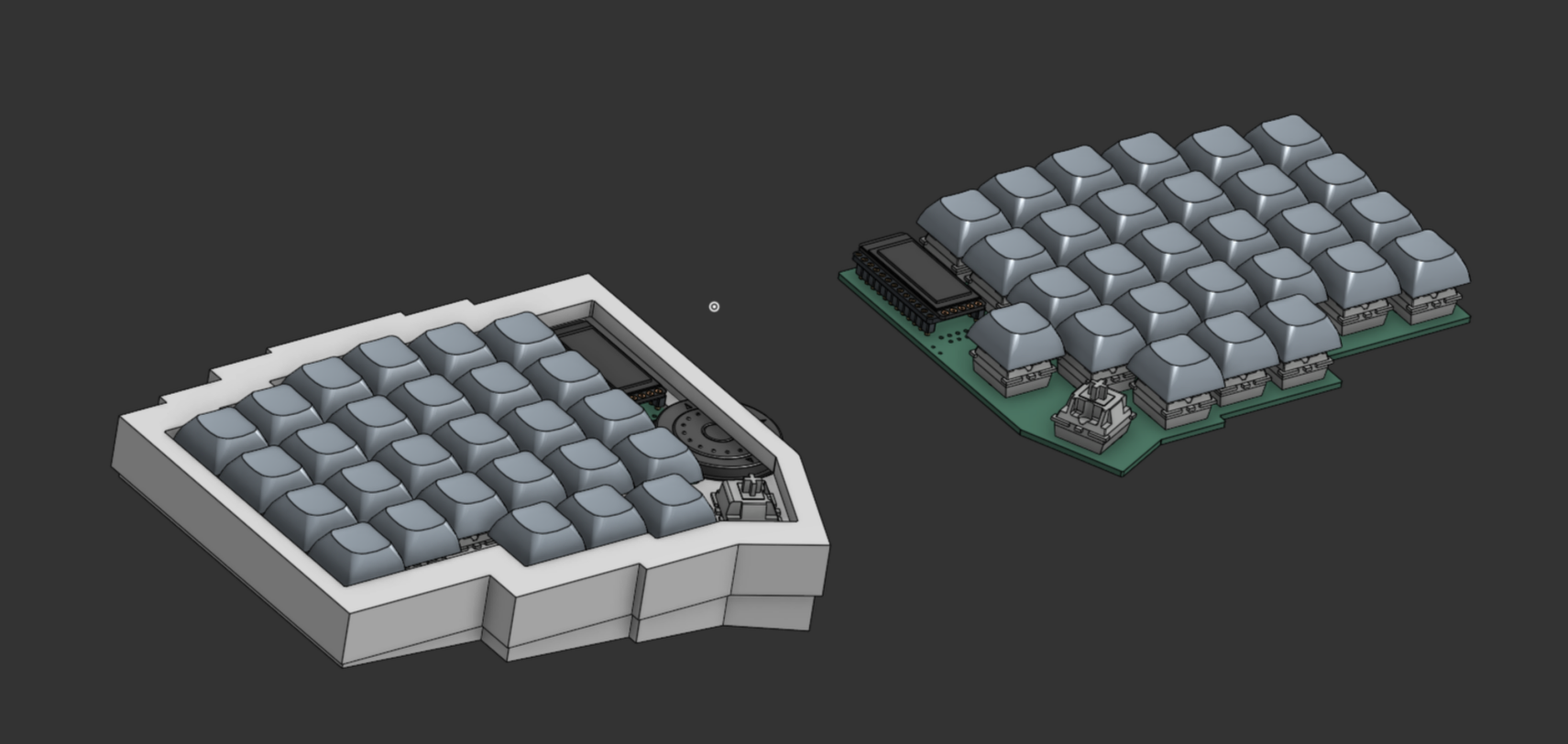

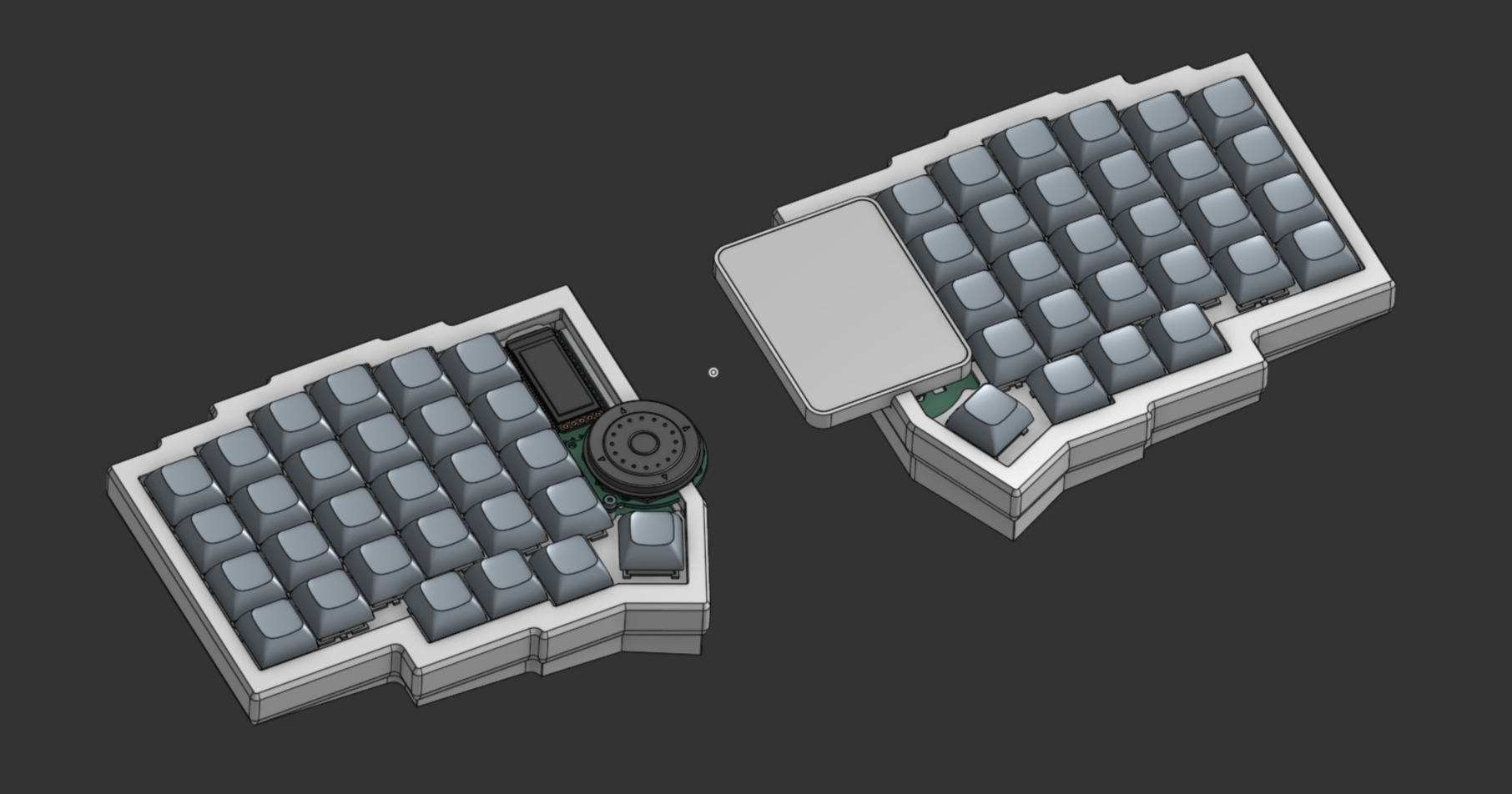

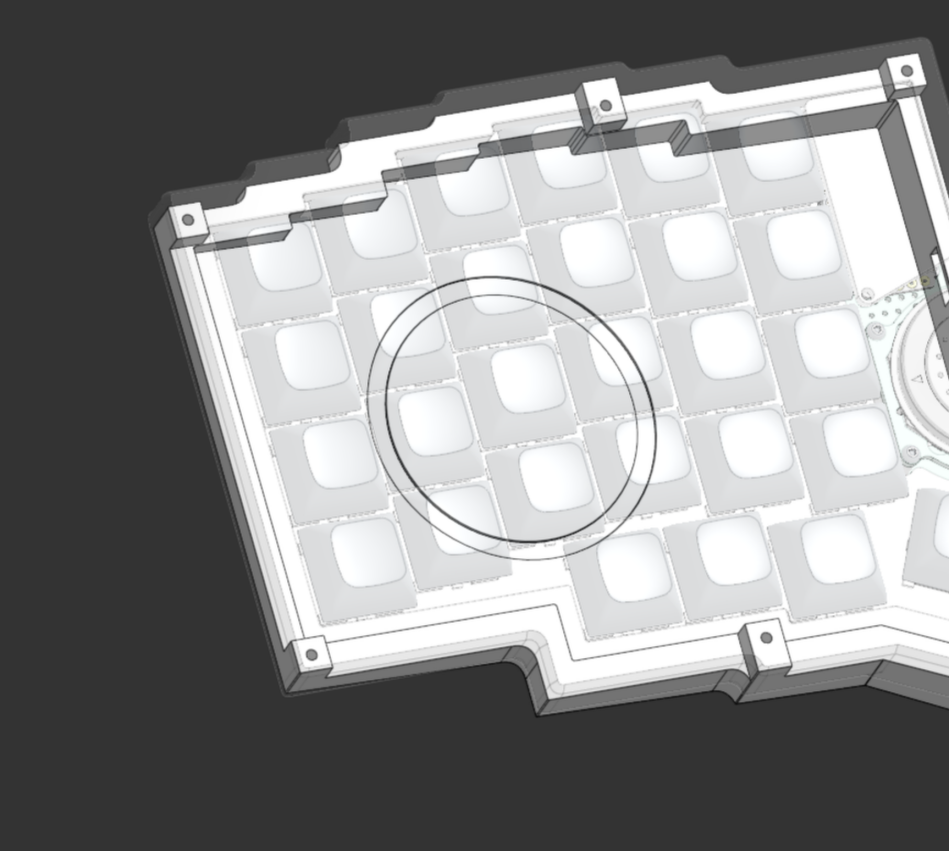

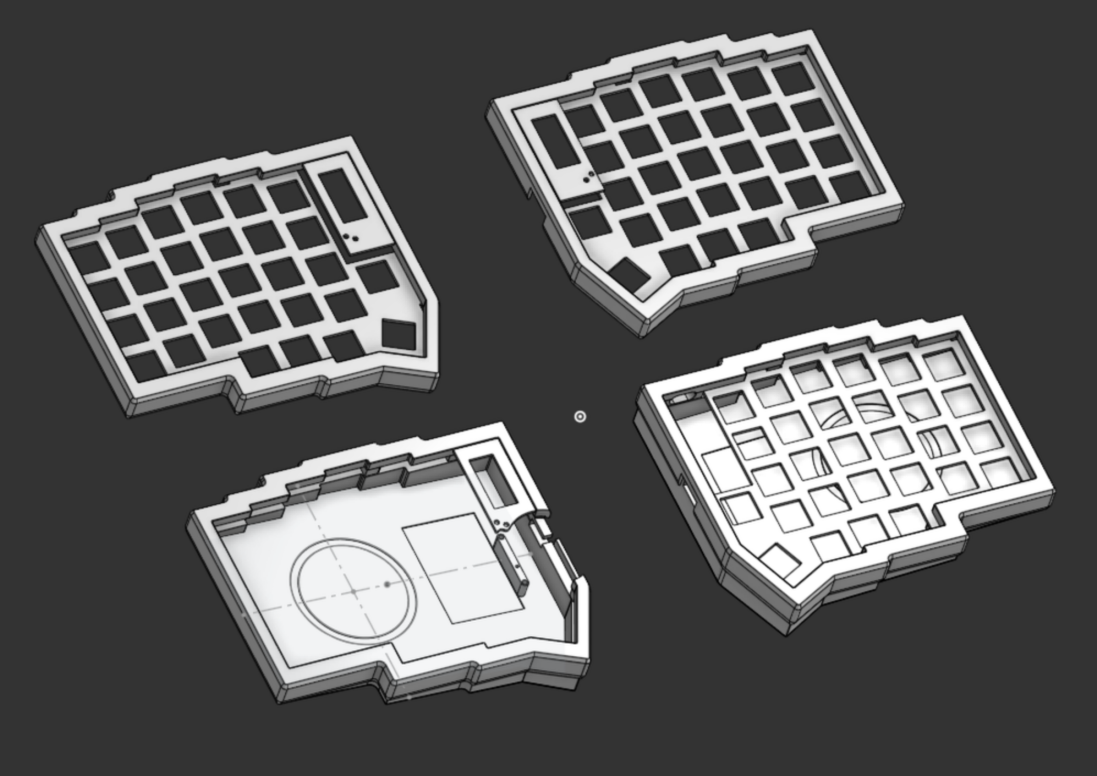

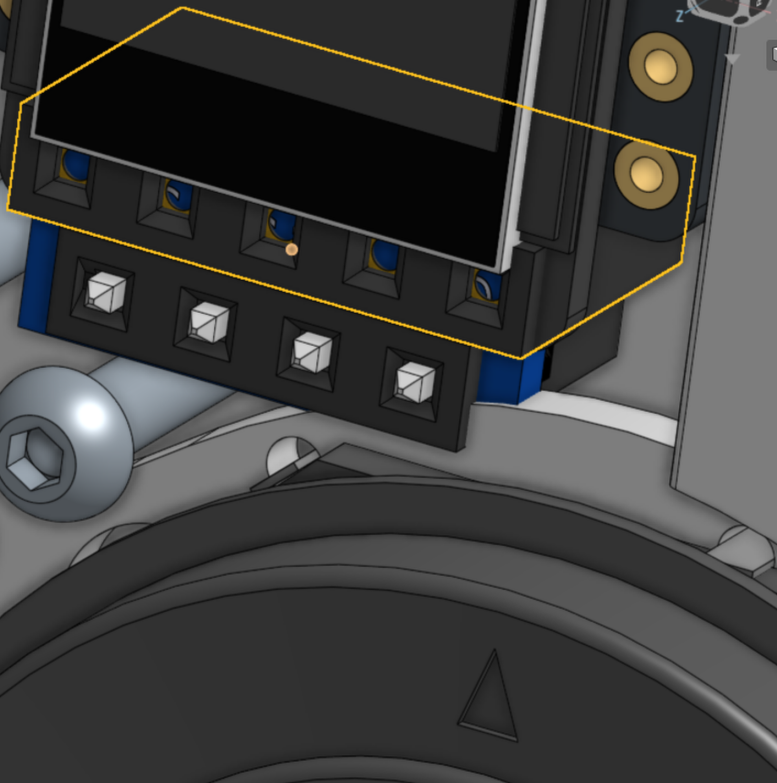

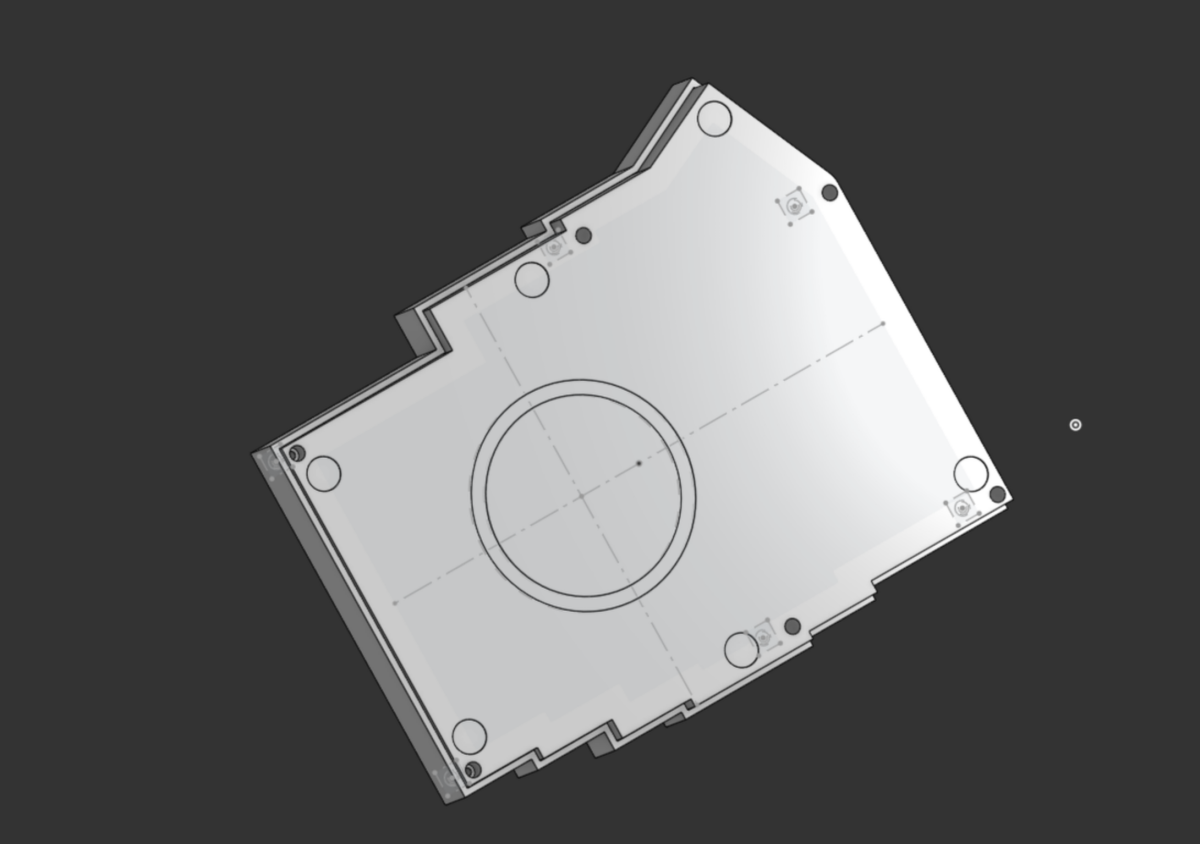

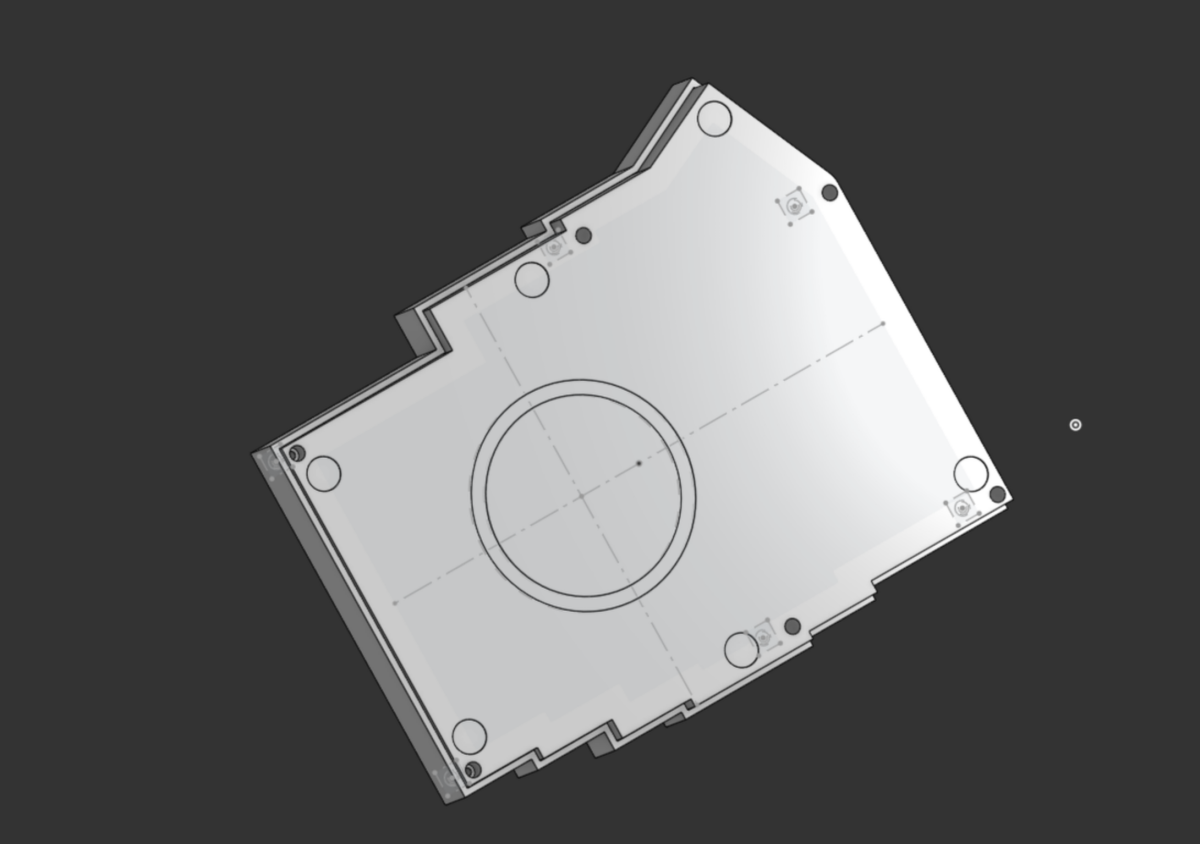

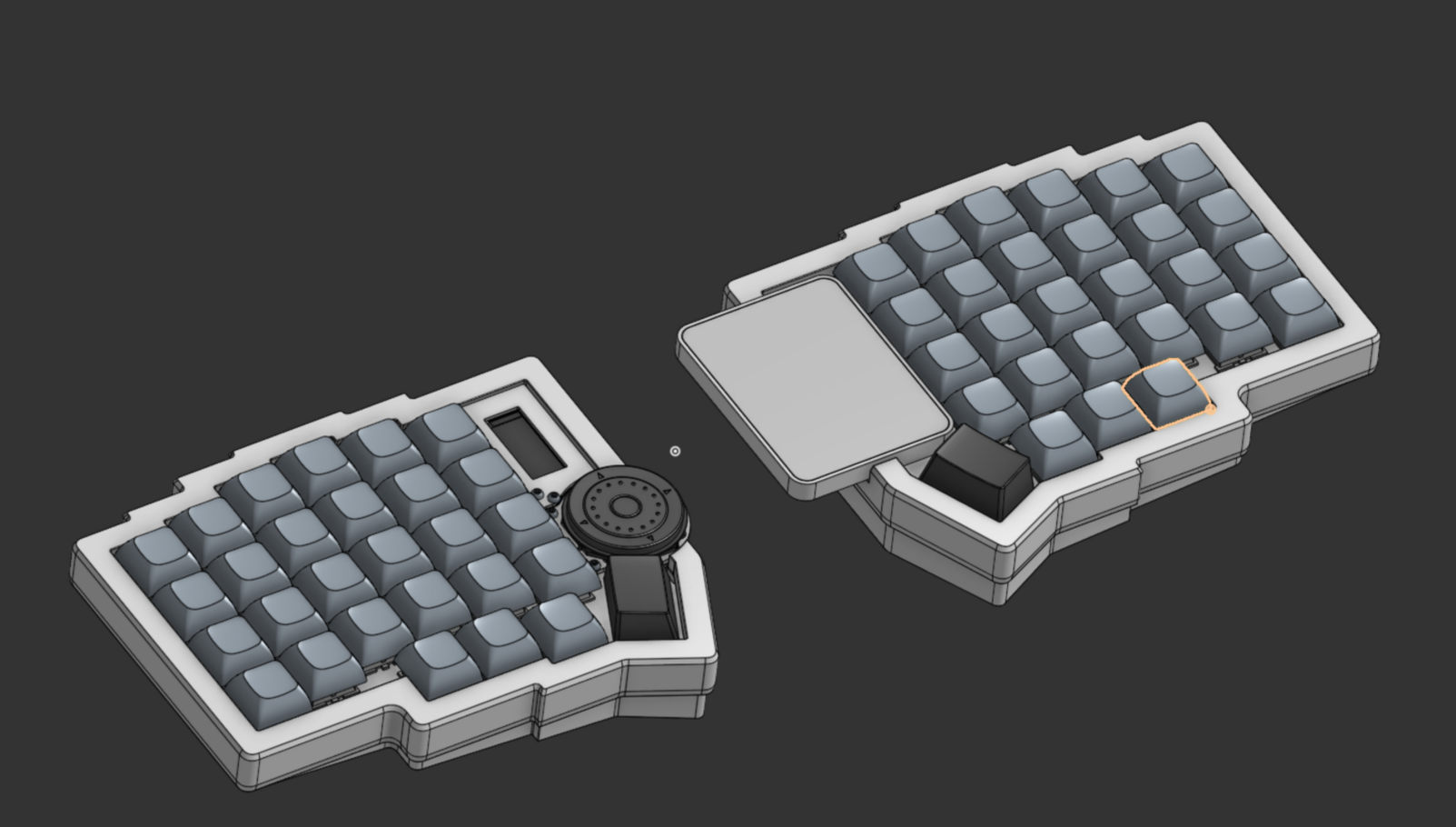

CAD more scafolding

- I added in the components into the cad with the keys in a sketch to plan out where everything's gonna go

- Although I am still missing the acrylic cover I'm gonna make to cover the mcu and display

Time Spent: 4.5 hours

July 26

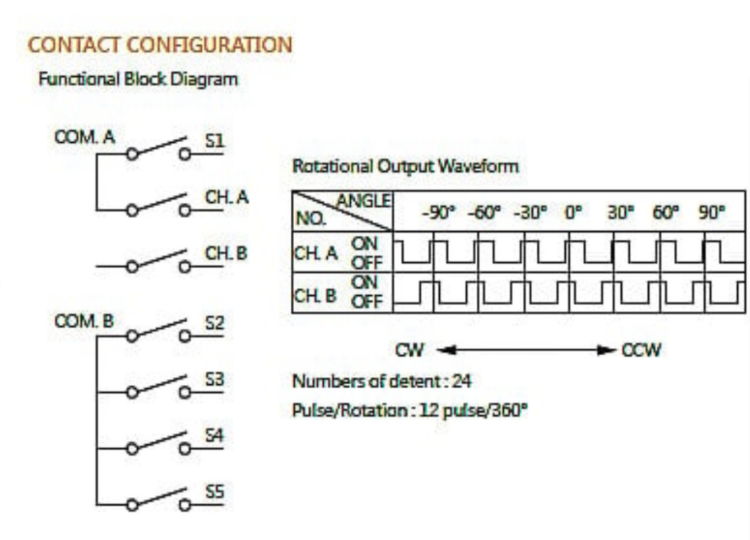

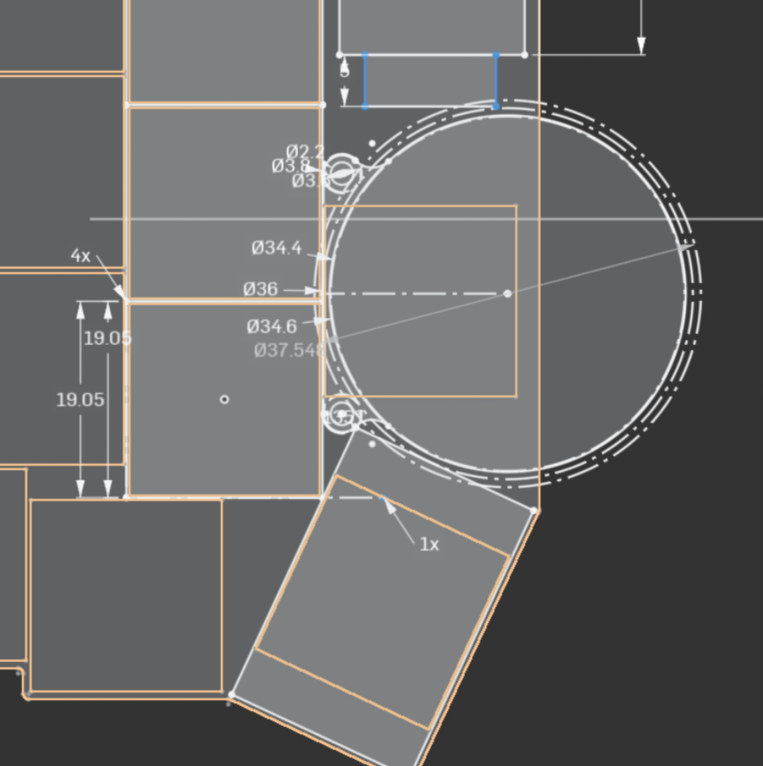

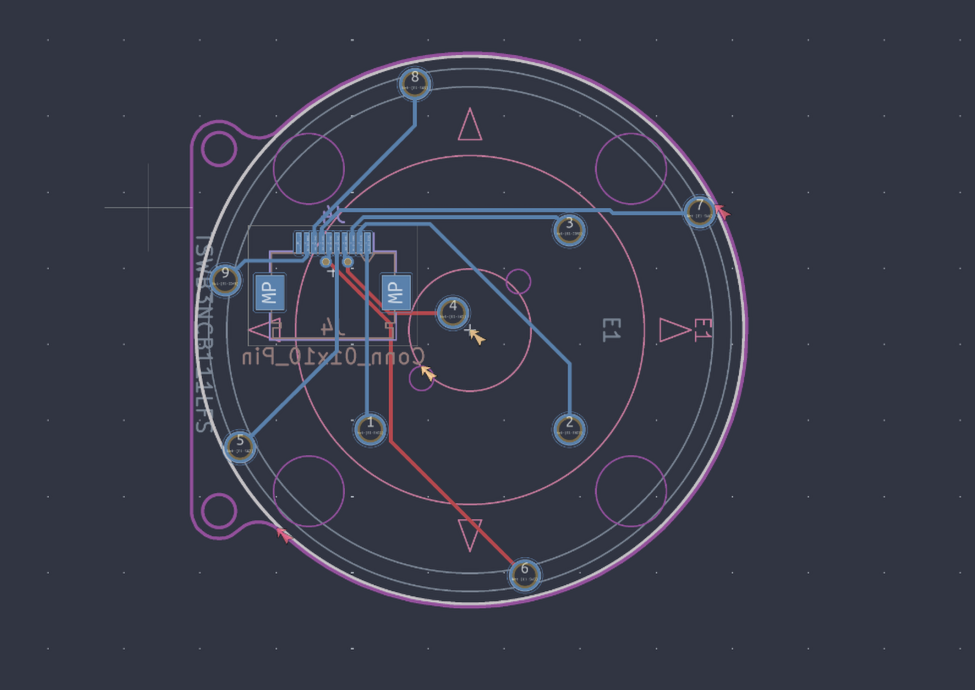

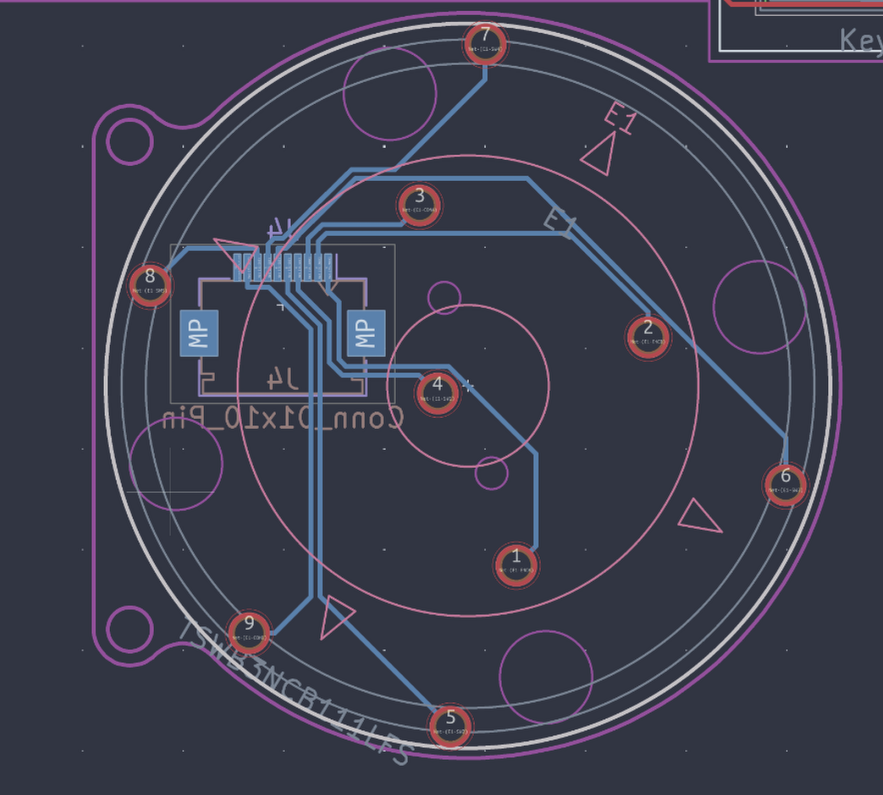

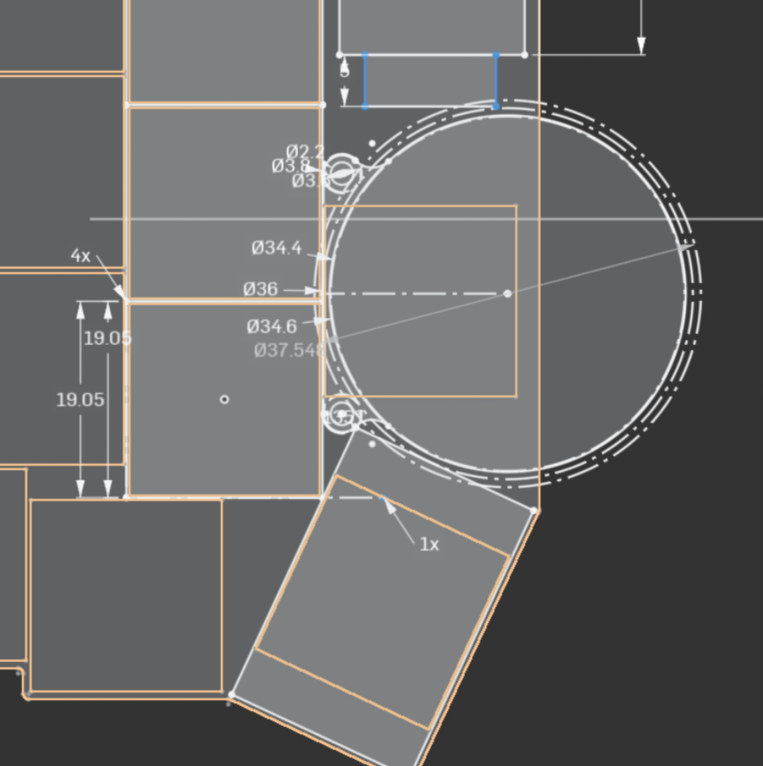

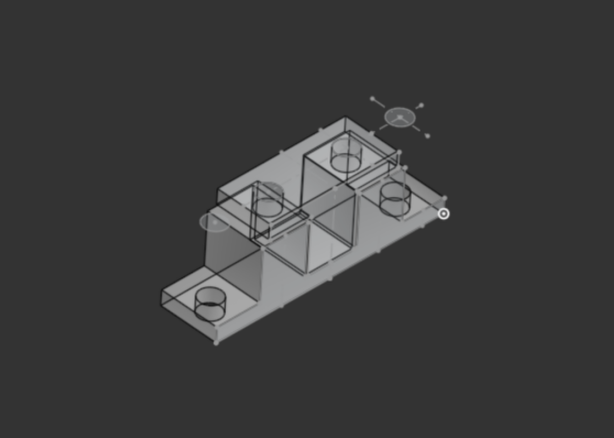

ANO Encoder

- Today I made significancy more progress on this encoder

- Made the footprint, which took a while as I've never done before and there wasn't one available online (THANK YOU DIGIKEY FOR THE AMAZING KICAD FOOTPRINT GUIDE)

- Some notes about this footprint is that it took a surprisingly long time and a pain to make and line up with the schematic although after some time I made it work

- I ALSO FOUND THE GREAT FH12 FFC cable connectors to connect the trackpad and encoder daughterboard to their respective halves after tons of time searching

- It also took sometime finding the footprint but luckly it was in the kicad footprints library :DD

- Also planned more out of this daughterboard pcb layout and dimensions in onshape

|

|

|

|---|

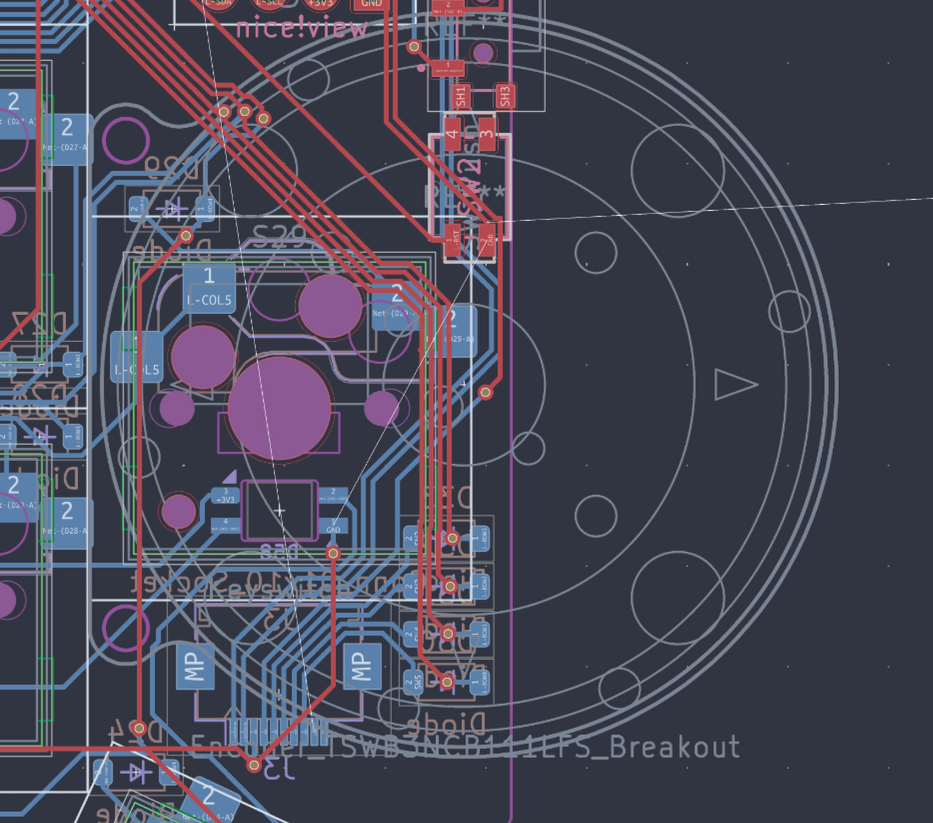

General PCB

- Realized that the spacing between the center of the led and the center of the switch was 5.08 mm not the 4.5 I eyeballed by looking it up in the Keyboard Atelier discord

- Making me change that entire thing in ergogen, then transferring it backk to kicad

- With that change and having the numbers on each of the components messed up I decided to renumber them in the schematic and then Kicad

- Then I went through it all and make sure each switch and led lined up with its counterpart in the schematic which was wayy too tedious

- At this point I settled on the leds going in a zig-zag pattern for wiring for simplicity and shorter run lengths

- I also started placing all of the diodes on one of the halves manually so I can have more space for fancy wiring and their traces for the switches

Time Spent: 6.5 hours

July 27

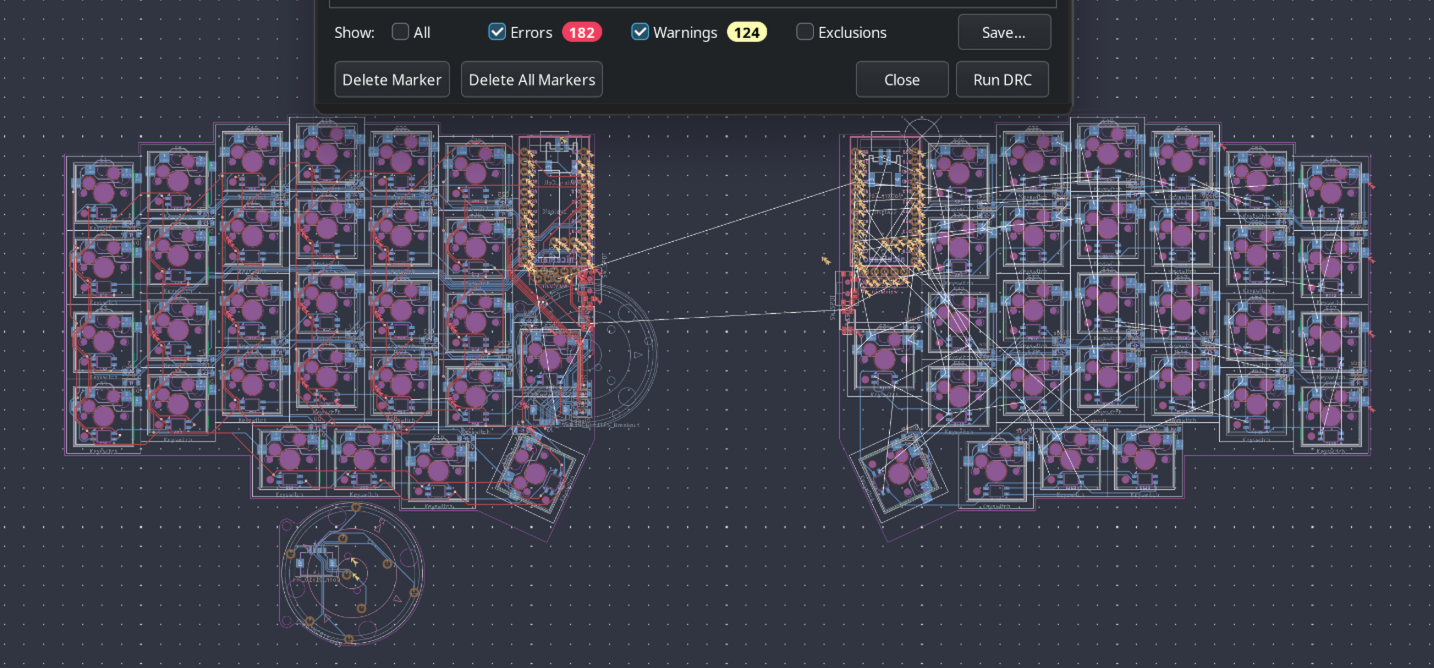

- First thoughts, I might not be able to finish on time because of all the trouble I'm having with the pcb and other responsibility now also popping up in the next few days :/

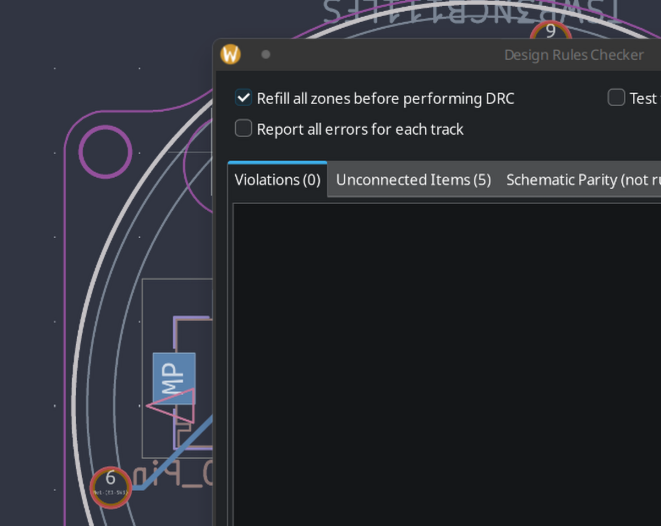

General PCB

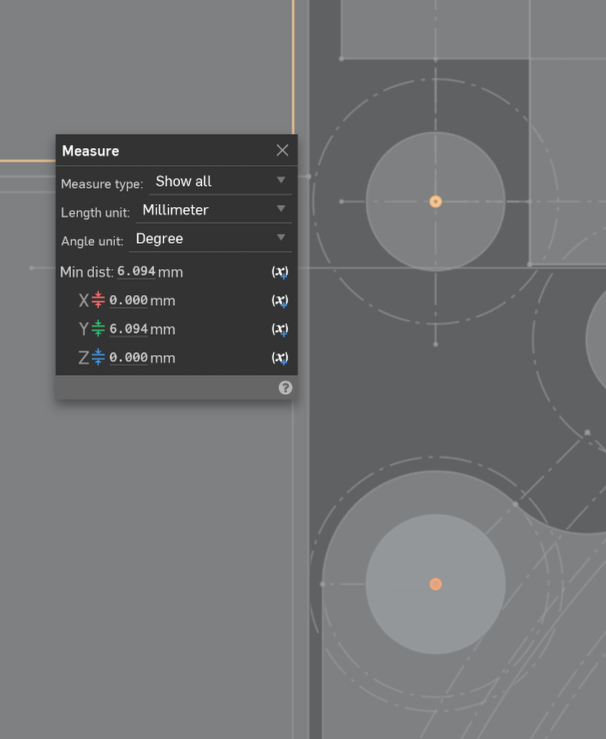

- In the morning I realized that the via's can't really be ontop of the pads so I changed each of them so they would be atleast 0.4mm away

- Continued routing this pcb and ran checks

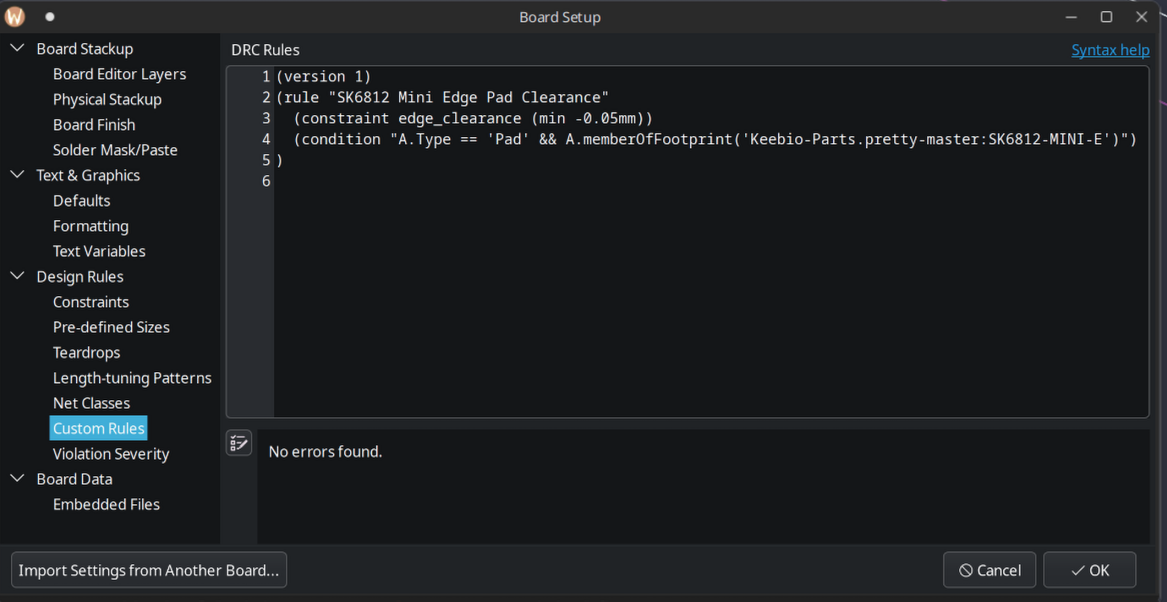

- This is where I got 1k+ errors due to my hacked together switch and sketch stuff, making me spend some time fixing that

- First with the switches I switched some of the holes to edge cuts and changing some of the settings and tweaking the overrides, along with the leds

|

|

|

|---|

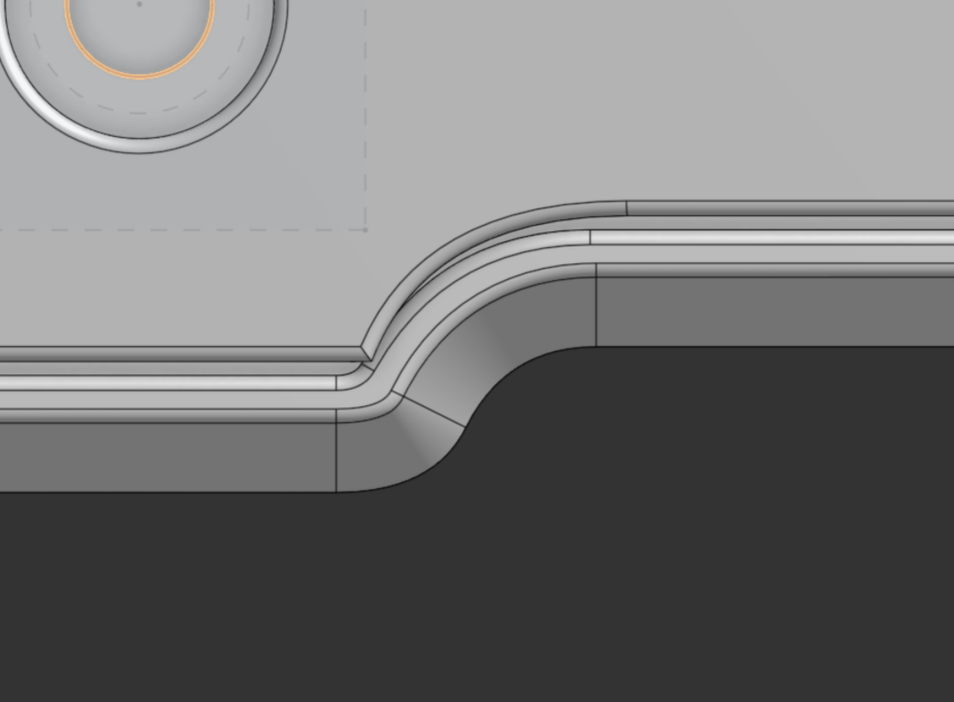

ANO Encoder

- Created the general shape of the breakout board first in onshape then moving it to kicad

- I might need to rotate it so that the 7 and 5 pins are away from the right edge as that would be where they would be most visible as they poke out a bit more then the others

- Final thoughts for today, I think I need to finish the left side entirely tomorrow and I might be able to also start on the CAD and finish that within a day due to my experience

- I also might need to do a bare bones zmk config without the fancy online key editing just for this project to be submittable on time

Time Spent: 7 hours

July 28

- Not sure why but I'm just having trouble focusing on this :// might be the amount of sleep I'm getting but I will try and get this done by hopefully end of 30th to leave the 31st for any last minute

- Also summer school has started once again which may become a problem in the next few days

ANO Encoder

- FINALLY SHOULD'VE HAD THIS 4 DAYS AGO

- Created daughter board footprint along with lining it up on the pcb with the connectors, also created a cutout so that the fpc connector can be passed through

- Also I rotated and rerouted the daughter board so it would work better

|

|

|

|---|

General PCB

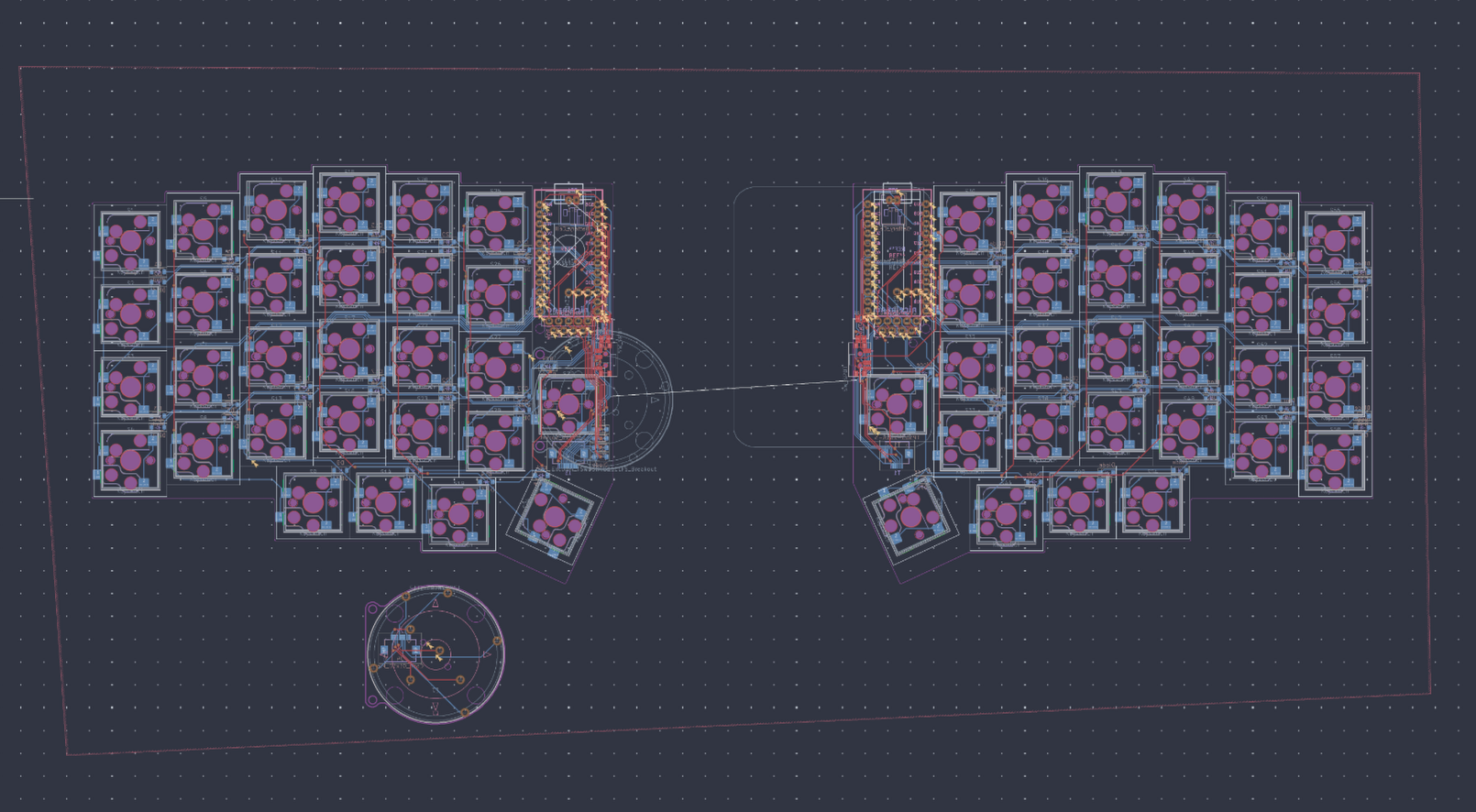

- Worked on routing so the left side is basically done and should be much faster to route the other with a blue print basically

- Got the errors down a bit more although they are minor and can be fixed relatively quickly

- Although I realized that this doesn't have the 0.5 fillets which I might add back with the help of ergogen

- Made the pcb exportable by fixing all of the outline errors with the mx switches and ano encoder

|

|

|

|---|

- Also looking back on this pcb after developing more of the cad I might move the mcu along with the displays slightly

- Additionally I need to figure out the mounting holes for the acrilic cover

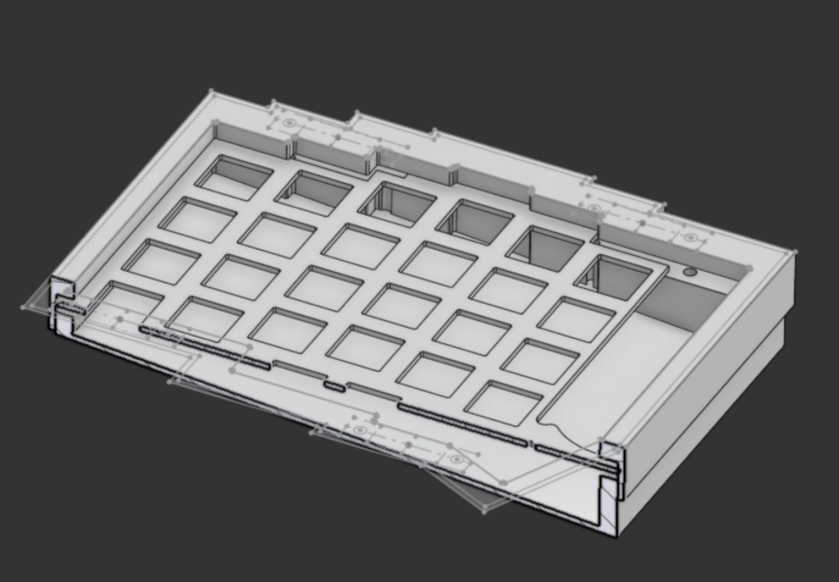

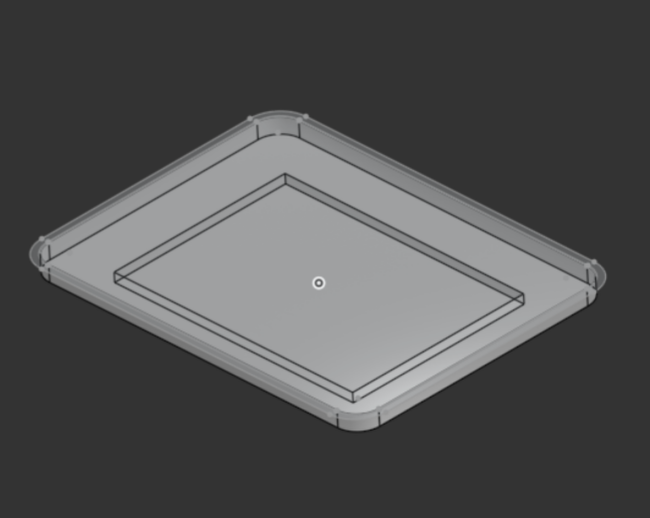

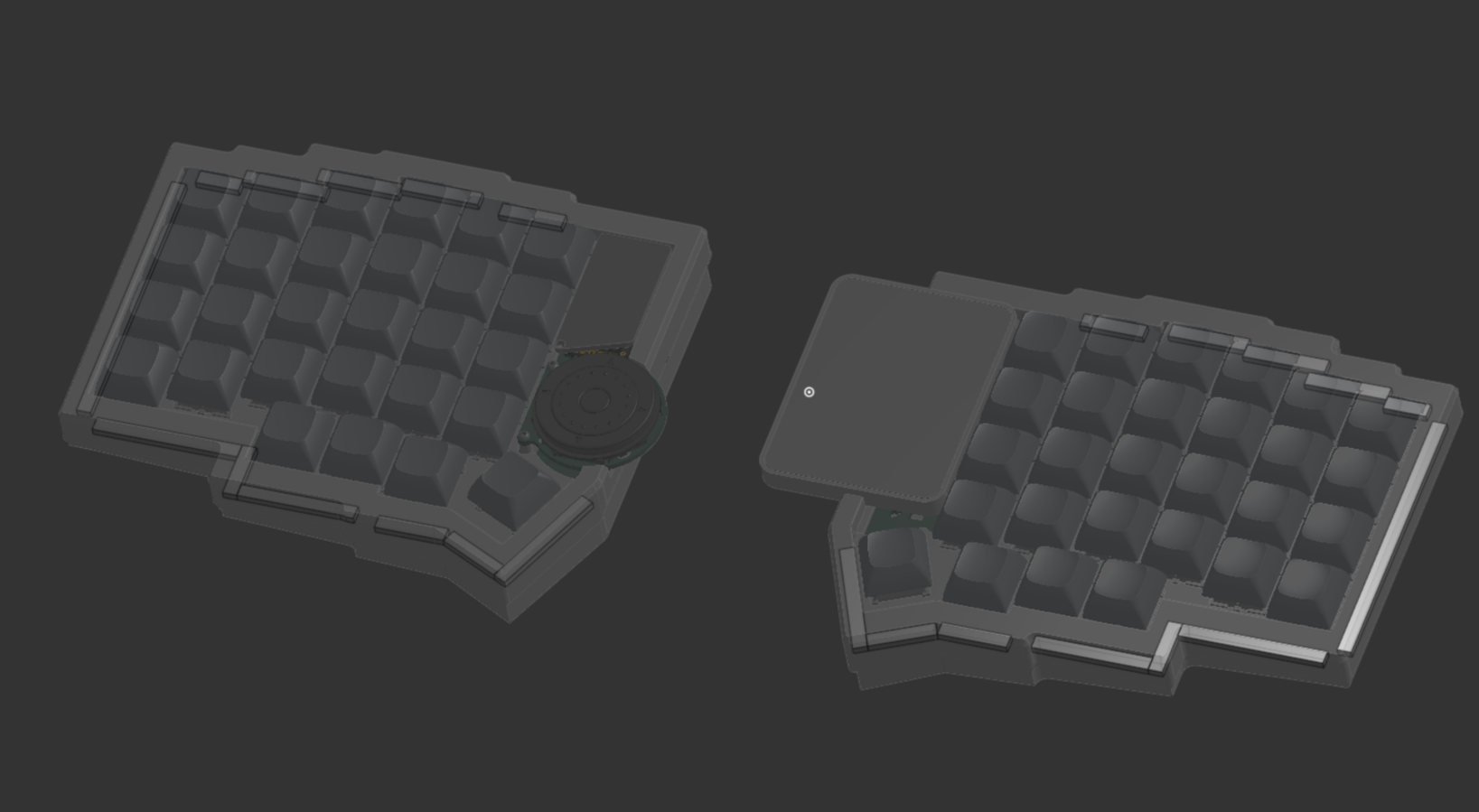

In the CAD this is also what I am planning so far

- Thicker bezzels (~7mm or less)

- Accommodate a ball catch mechanism like in the rd75

- and to house a gasket mounting system

- This will also most likely be a poron foam strips thing in the front and back mounted to the plate

- Although this might be ditched and reduced to just a plate isolating system due to time and wanting the keyboard to be relatively thin

Time Spent: 7 hours

July 29

ANO ENCODER

- Redid polarity of the encoder to work with the type A ffc cable

- Also slightly reduced the size of the daughter board

|

|

|

|---|

General PCB

- Updates to pcb by editing ergogen then importing into kicad to have the .5 fillet on the pcb so its smoother

CAD

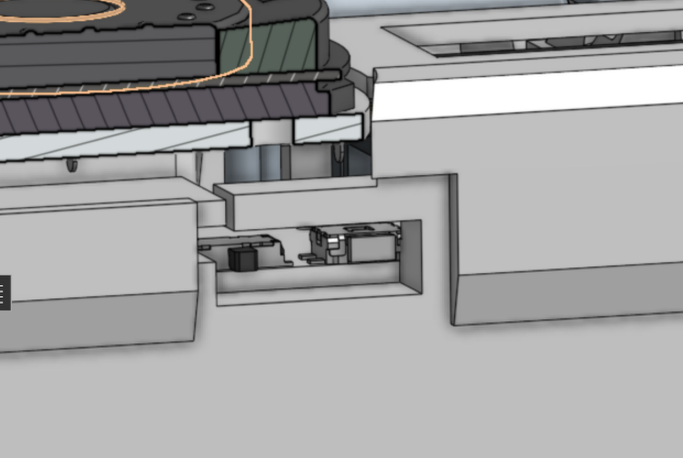

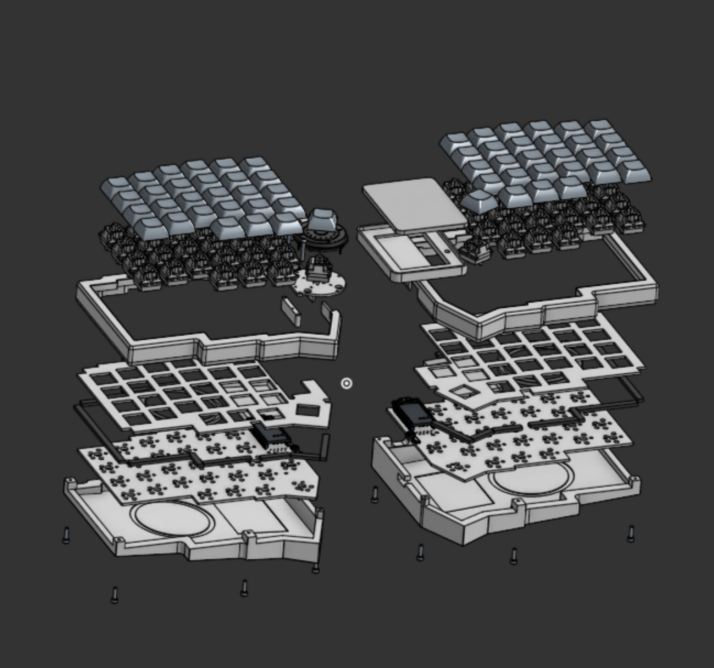

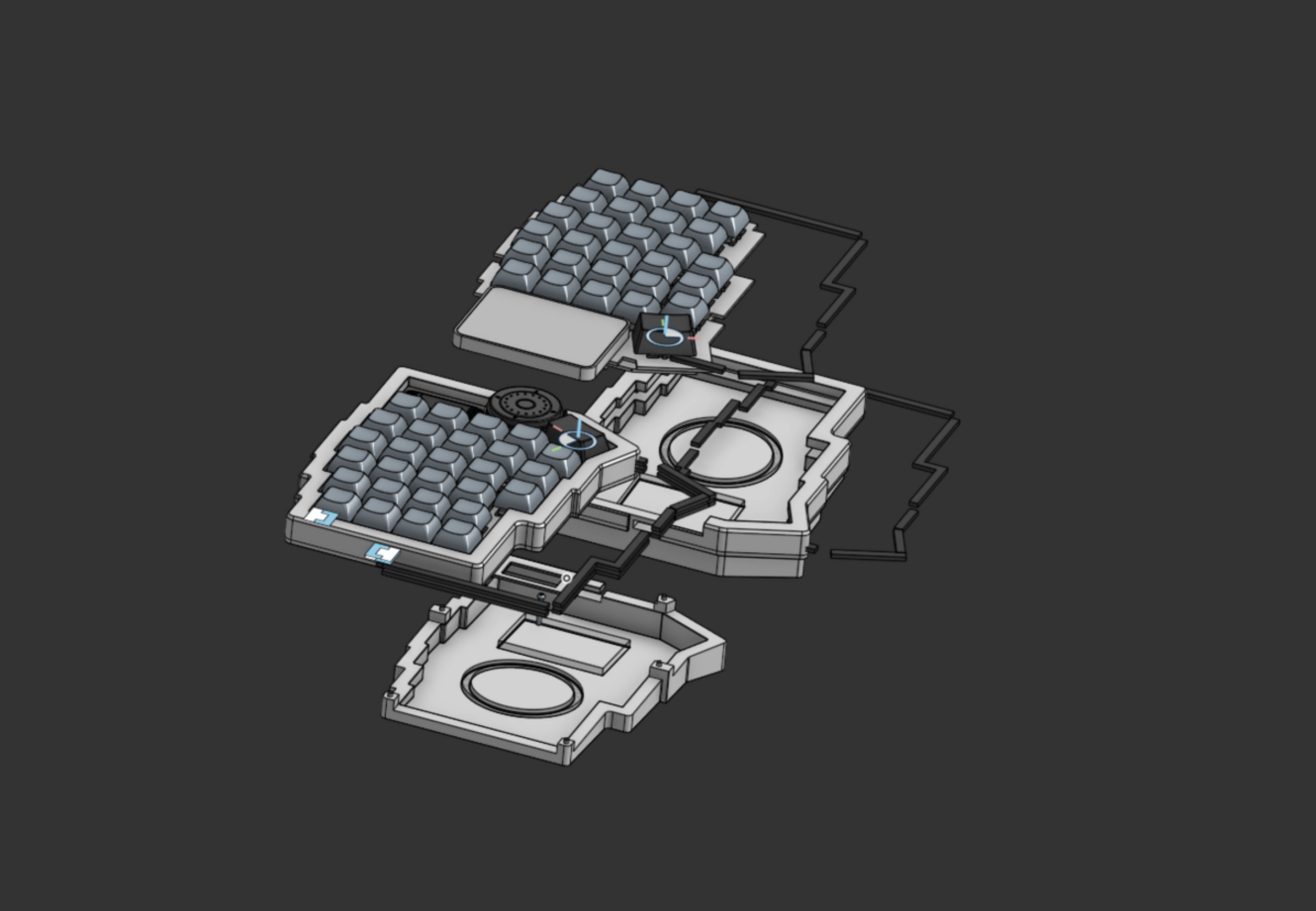

- Worked on CAD, added the plate, top case, and bottom case so far

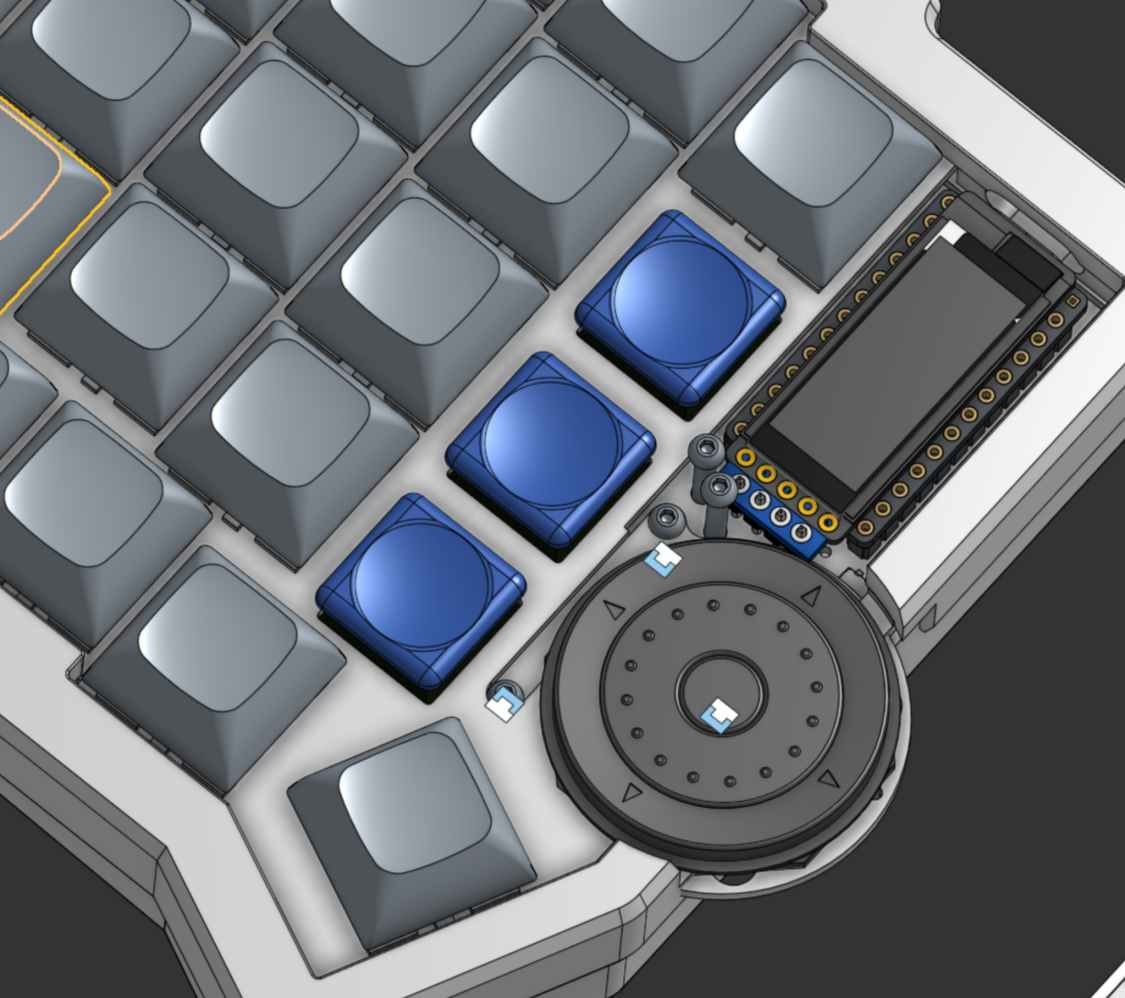

- I also added the supporting such as the headers for the mcu, and adding in the ano encoder with the nice!view display

- Additionally I laid out where the ball catch mechanisms are suppose to go along with the poron gaskets

- I spent a bit too long on figuring out how to create the case in the way I wanted due to all of the variables, although I figured it out in the end with a bunch of sketches

|

|

|

|---|

Time Spent: 8 hours

July 30: LOWKEY REALLY BEHIND

CAD and PCB Stuff

- Worked a bit on placement of the trackpad and creating a bounding box, starting on a case for that

- Also rearranged a bit of the mcu with the display so they would all fit correctly above the switch

- Additionally I made sure the usbc wouldnt stick past the pcb so I made it 0.2mm away from the edge to play it safe

|

|

|---|

before and after!

|

|

|---|

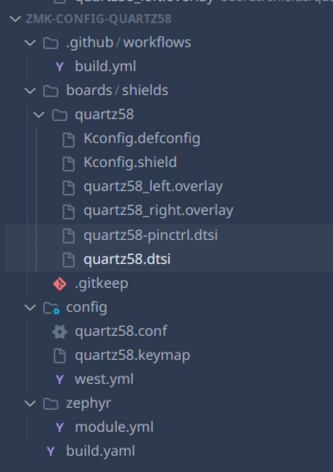

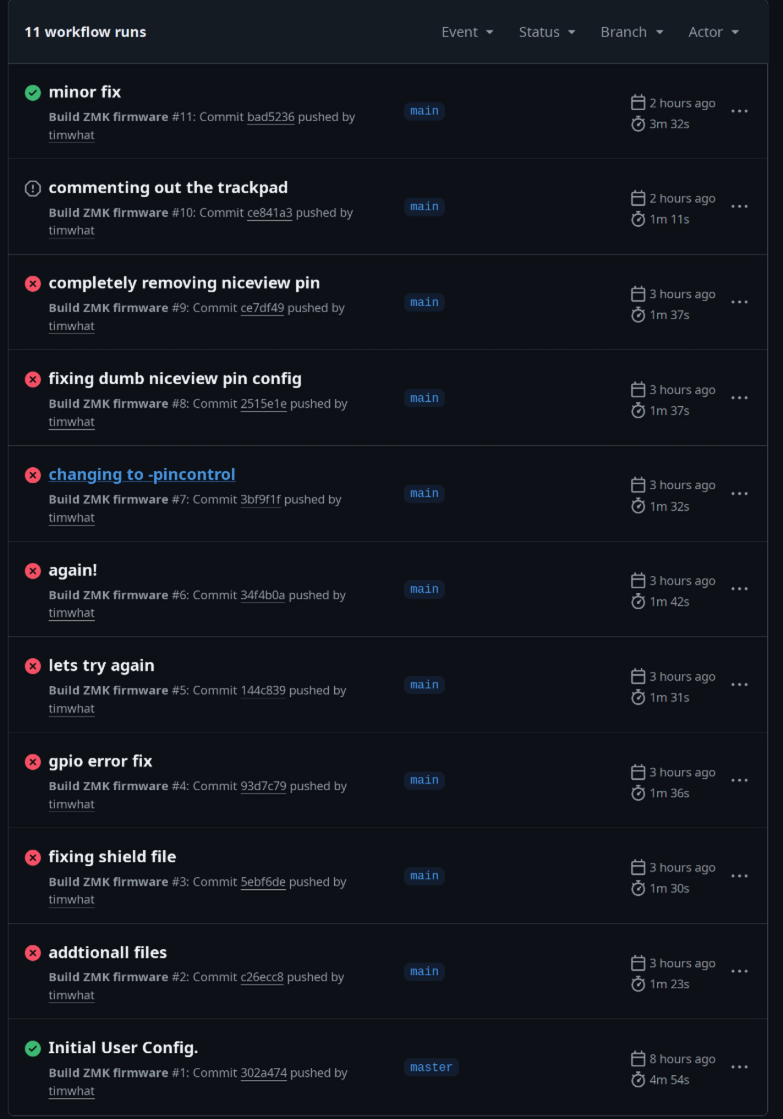

MONUMENTAL ZMK RUN

- I first imported the standard lily58 zmk config

- Customized to fit my pins, added my own shield and the encoder with its 4 buttons

- When working on it I realized that I needed to make the numbering consistent so I make the go from 0 on the left and +1 as it got to the right cols

- Swaped around the cs and rgb pins to high frequency ones because of reading through the docs it recommended that

- So then I was ready to compile and it just wouldn't work so I used github co-pilot to help me understand the errors along with a friend, and then many iterations later...

- After commenting out the cs nice!view and trackpad stuff it compiled!!! https://github.com/timwhat/zmk-config-quartz58/tree/main

- So if I have any time remaining for this I will continue to make these features work and add additional features such as cool rgb affects, If not I will work on it while I wait for my parts to ship

|

|

|---|

Time Spent: 7.5 hours

July 31: Basically done

- Will write more in a few hours to document what's been done but completed wiring on both sides of pcb

- I will clean up the wiring on the right side as it was really rushed to get it in by the deadline (making the traces look nicer with some pcb pattern)

CAD and PCB Stuff

- Completely finished routing everything

- While doing this I made some changes to schematic to make routing some of the traces easier

- Created Gerber files for quote

- Created TPS65 Mount along with other minor stand offs

- Continuously refined case

- Added Magsafe for tenting support and gaskets for visuals

|

|  |

|  |

| :--------------------------: | :--------------------------: |

|

| :--------------------------: | :--------------------------: |

- Wrote BOM list

Completed README requirements

My Next Steps

- Rename the files in the kicad to match conventions

- Continue to polish the pcb traces and silkscreens (currently FULLY working this is just for asthenic)

- Continue to refine case if any ideas or thoughts for improvements pop up

- Complete ZMK as it compiles and test on the real keyboard once received

Time Spent: 11 hours

August 1st

- Today I just caught up on school work and fixing my sleep schedule, and trying to get unburnt out from this

- I also updated the gerbers as I switched JST footprints so they are through hole and I could source it to typeractive

Time Spent: 0.25 hours

August 2nd

- Woke up to a slack message and my rereview being rejected sadly :/

- Due to this not qualifying for a 10 point project despite my nativity thinking it would and only checking with other highway members and not a reviewer.

- I had to rethink what I wanted out of this keyboard, as I can not afford the difference in its current state

- Basically entire day until late evening I started working on this

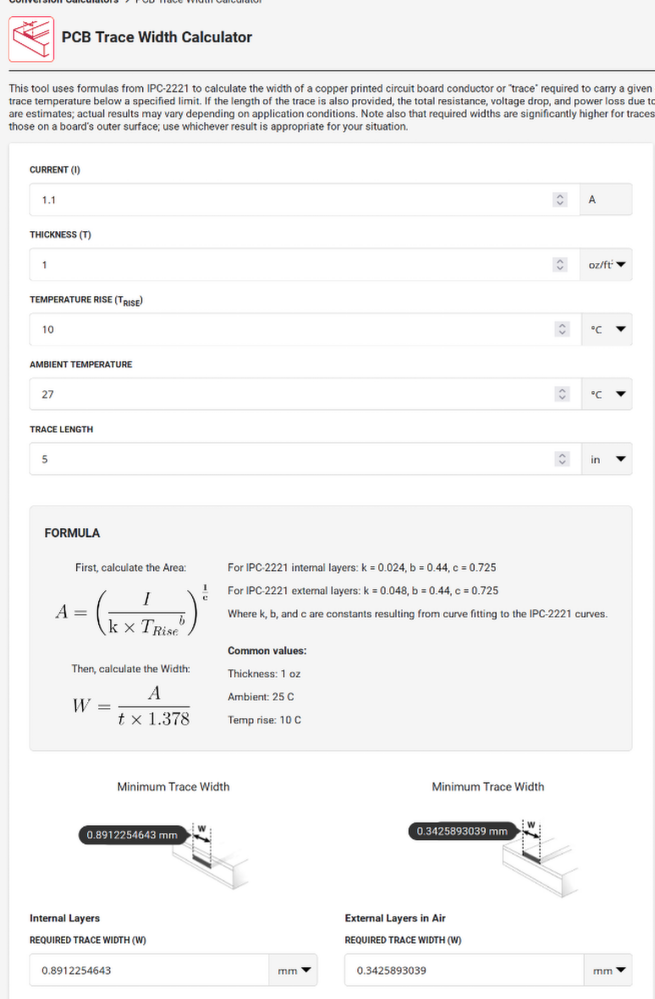

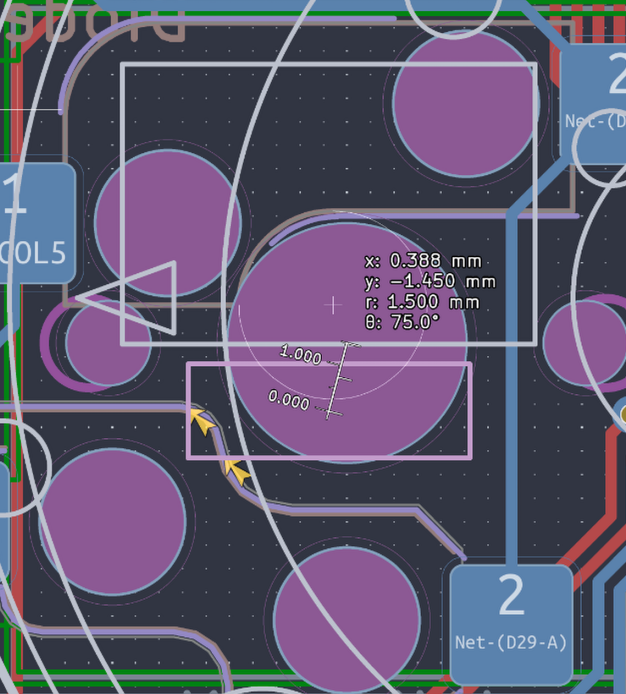

PCB - SK6812 Mini Power Problem

- I also realized that for the LEDS, I felt like them having such thin traces felt wrong so I decided to dive deeper

- After looking through its datasheet by Adafruit, it takes 1mA as static, 12mA per RGB so 37mA total at 3.7V, 29 LEDs per side, resulting in 1.073A per side.

- Going into digikey trace calculator it says the min trace with in external layers, in air would be 0.34mm, so I decided to go with .45mm trace widths to be save IF ANYONES READING THIS PLEASE CHECK IF THIS IS CORRECT

- Then I made sure the led's used their own nets, and then I set them to this new .45mm trace witdth

- This is where I ended this part for the night I will figure out this routing tomorrow morning

BOM Update

- Decided to ditch the encoder and trackpad cover for now among other items that I will save up for and purchase my self at a later date

- Also switched the battery from 2000mAh to the 750mAh one from typeractive because they come with the jst 2.0mm connector so I dont have to buy that + slightly lighter and I don't want

- Also optimized everything to save on shipping so I switched around the connectors to use mouser and yea! I'll hopfully have more progress tomorrow as I am less busy

Time Spent: 2.5 hours

August 3rd

PCB

- After spending a afternoon jumping down the rabithole of powering these sk6812mini's looking in various discord servers I found out you also need level shifters and capacitors for these leds are 5v

- Since by board doesnt really have room for this + this would add tons of complexity I finally made the call to ditch them, they will prob be present in the next revisions of this board

- Also I found leds such as the sk6805 which does work at 3.3v, but they are wayyy too small and difficult to solder for my experience so yea

- Thus now that I didn't need the LED's, instead of having to choose to use the mx or choc sockets in a switch location I remembered that I saw a board that used both

- Since I couldn't find a footprint for this I decided to repeat what I did with the og mxchoc hs footprint and just make it again but the choc socket this time would be on the bottom

- Also I had to turn some of the holes into edge cuts so they wouldn't produce a warning where the two holes were too close

- So after removing the LED's and changing the footprint I routed everything on both sides which took some amount of time and I added a inverted thing to make it look cool

- I also added this pattern which I might change to like a grid later on before ordering

- After that I updated gerbers and got a jlcpcb quote again so its up to date

- Considering cleaning up more of the traces to make this pcb perfect but, everything currently works!!

BOM

- Changed some stuff around for formatting and switched the 10 pin fpc cable to 6cm as that place better fit that.

Time Spent: 4.5 hours

August 4th: Getting ready for review

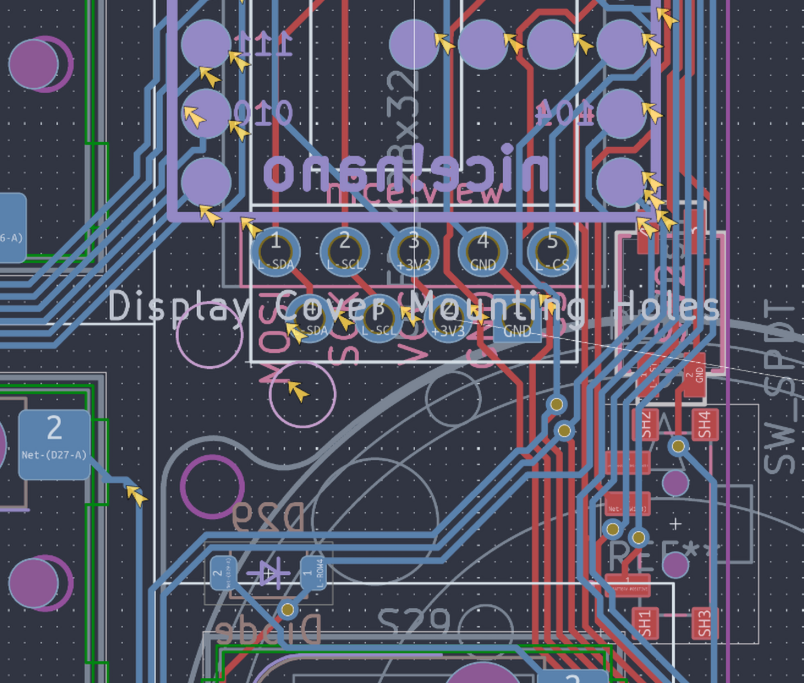

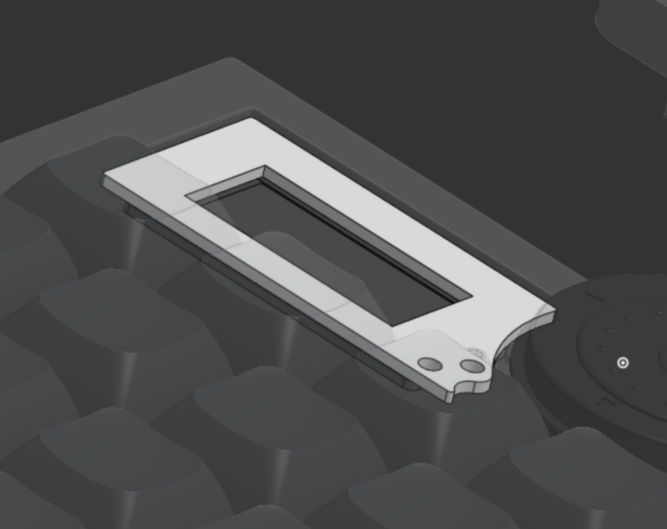

Display

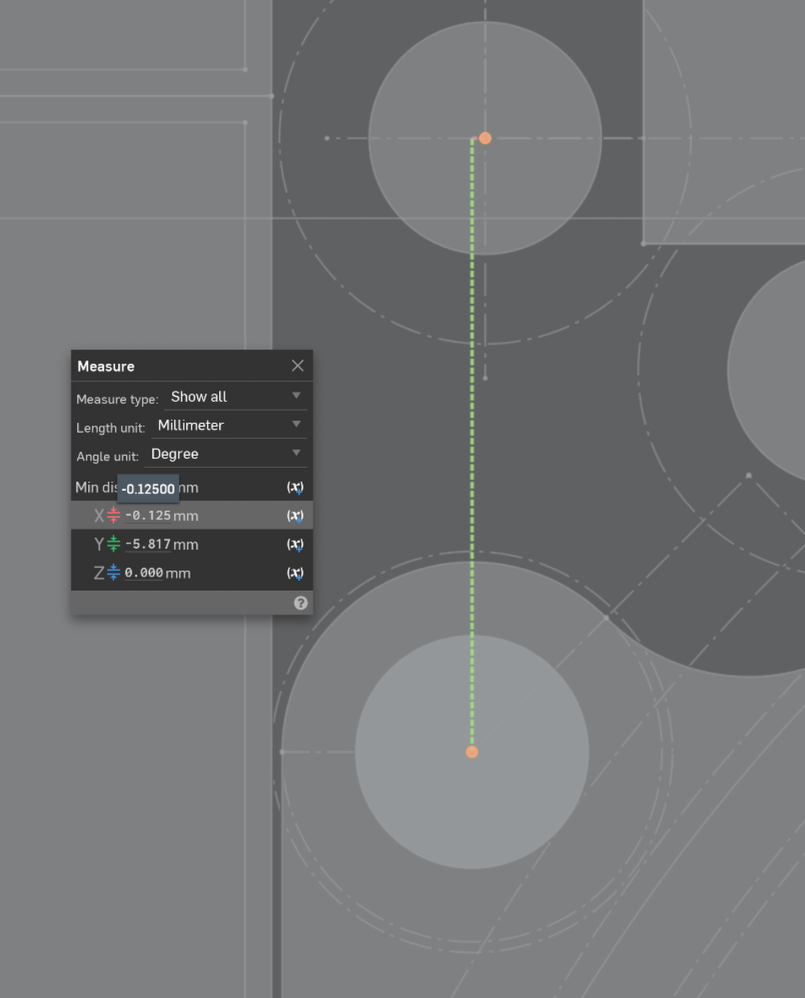

- For the display I realized that having only one pointing point with 1 screw was going to be unreliable due to it being able to rotate the cover while it is there, so I added another hole in the pcb!

- I then added that to the CAD and switched this display cover so that it was 3d printable as the polycarbonate version was out of my price range as now I'm working under the 6 point.

- Although it wasn't until half a day later in the late evening i realized that these hole locations are not the most great.... So I re aranged them again for the 5th time, also requiring to edit the encoder's pcb and foot print to get this perfect

|

|

|---|

- When updating the pcb however the edge cuts would just not line up no matter what even with cords, so this is where I called it for the night on this.

Power Switch and RST Button

- Due to me having a 3D printer and probably wayyy more time to iterate on this cut out to get this absolutely perfect

- I for now settled on this, as anything else currently, due to the gasket mounting would make this extremely complex and it would have to go up and down with the pcb n' stuff

- Eventually when I have the components I want to make something like this as I feel as though it'll be much easier to prodotype this

Magsafe and Battery Mount

- I decided to cad out basic models of these components so then they can go in their corresponding cutout for alignment!

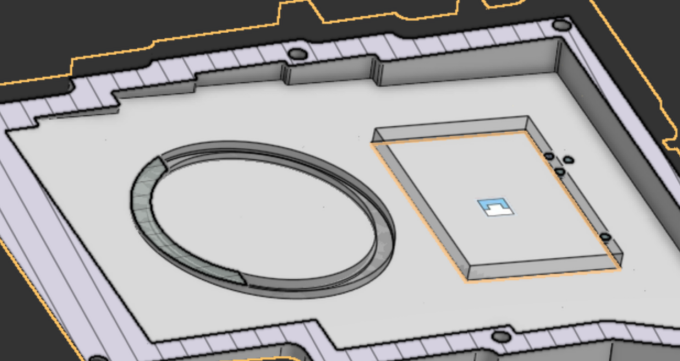

General CAD and Exploded View Experimentation

- I took this time to finally recolor the pcb white, so it matches what it would look like in real life.

- I also started to create a exploded view of the keyboard to show its complexity and to easier explain components, as now there is a really nice visual aid

- To further help I may use Onshape Render Studio to create nice renders of this keyboard

- As for a while I won't be using this keyboard with the encoder as I don't have the funds I also created a version of the keyboard sides without the addons! I will later add them into their own assembly and nessary electronics n stuff!

Time Spent: 5.5 hours

August 5th

- Today I started off just by looking through the stuff and adding the oled screen to see if everything would fit correctly.

- Espically as, I know I am extremely indecisive so I wanted this to also work really well with choc switches if I ever decide to switch to them later.

- When I did this it worked perfectly althought, I might in real life need to trim some of the actual header to make it fit due to the combination of the thumb key placement, the tolderances of copper to outside, causing the daughterboard to be this big, and inability to move the display up

- Although I did move the display .475mm closer, which I didnt before as I had traces running inbetween the pins, additionally I couldnt move it any more up due to the boundaries of the pads

- But after when looking this over in the CAD the headers would overlap soooo I had to move them back :/

Them headers touching

Not Touching/Fixed

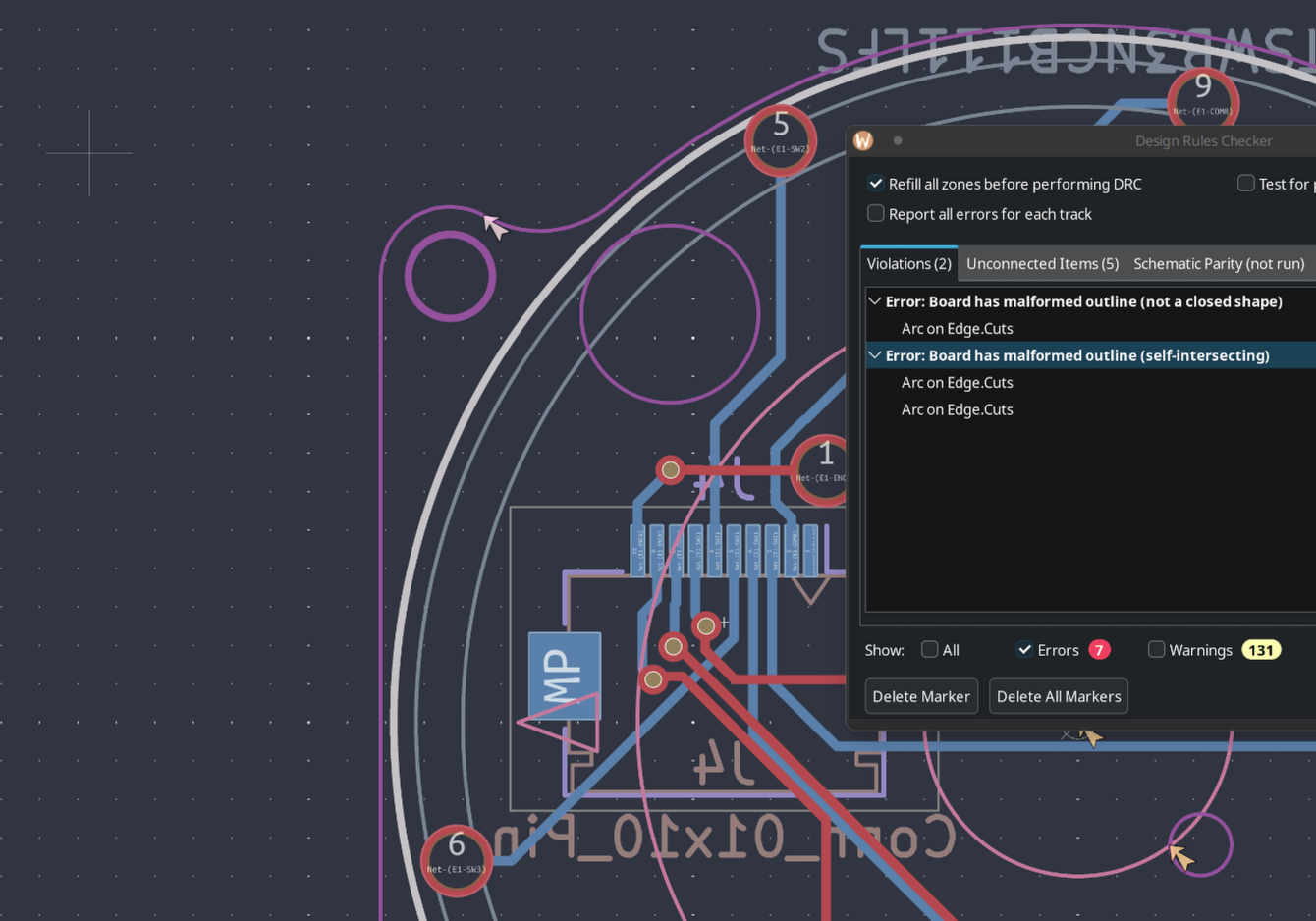

- Working on the daughterboard it just wouldn't remove the self-intersect wrror on the edge cuts, it as ocurring between two arcs so i tried to add a straight line inbetween, and still no luck, I have a theory that i was related to it being connected to another arc so the combonation of these two was causing a error later down the line

- Hours later I finally solved it, it was a combination of this being really complex, with two arcs interspeting and the entire thing not being complete soo I just connected everything (this was really painful to go back and fourth on the onshape and kicad to figure this out)

- This part is a expansion on yesterday so not that indepth

- Because I basically redid the shape of the daughterboard I updated the acording footprint and their location on the pcb so they were still good with the hole locations for the fpc cable pass through, below is it being unaligned and fixed!

|

|  |

|  |

|  |

| :---------------------------------------------: | :-------------------------------------------------: | :--------------------------------------------: |

|

| :---------------------------------------------: | :-------------------------------------------------: | :--------------------------------------------: |

- I also created little indents in the bottom case so my 8.0mmx1.5mm rubber feet can fit snug and are more difficult to remove

- While I was at it I also added a 0.1mm indent for my magsafe just as a visual indicator of where it is

- While looking around the case I found out that some of the fillets were not really lining up between the bottom case and the top case so I decided instead of using the fillet tool that I would just manually do it as I had much more control with the sketch

- thus creating a much better fillet n stuff

- And then when there were places where this wasn't possible I just added a .8 fillet along with a .2 on the insides

- Getting me here, the basically complete CAD!

ALSO my excuse for getting it so close to the deadline is because of summer school (I am in pain.) and onshape while updating one of my context's decided to crashout on me :/ but I fixed it pretty quickly resulting in the picture above!

Time Spent: 6.5 hours